Material Composition:

PETG PlasticPrice Range:

$1.28-$1.92/kgA 0.5mm PETG plastic sheet is a thermoplastic polymer known for its durability, transparency, and ease of fabrication. It is commonly used as packaging material in various fields.

PETG (Polyethylene Terephthalate Glycol) is a thermoplastic polymer known for its durability, clarity, and ease of fabrication. A 0.5mm PETG plastic sheet is relatively thin and is commonly used in various applications due to its excellent properties.

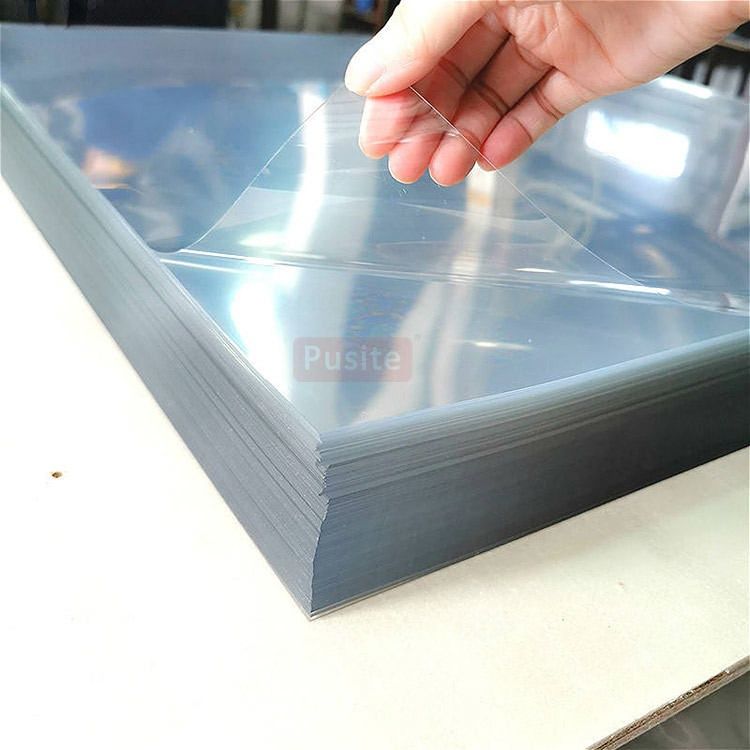

1. Clarity: 0.5mm PETG plastic sheet is highly transparent, making it suitable for applications where visual clarity is essential.

2. Durability: 0.5mm PETG plastic sheet has high impact resistance and is less prone to cracking compared to other plastics.

3. Chemical Resistance: 0.5mm PETG plastic sheet is resistant to a wide range of chemicals, enhancing its usability in various environments.

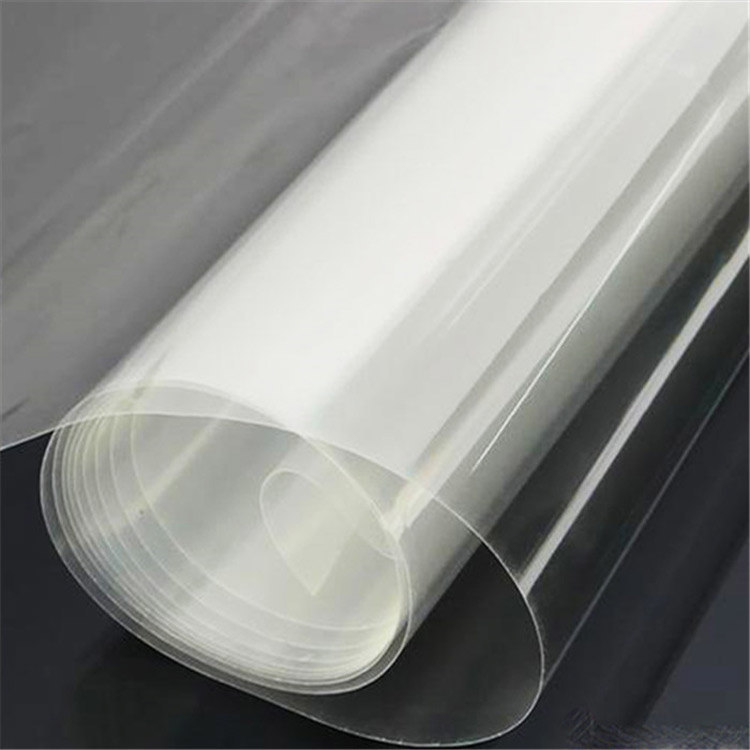

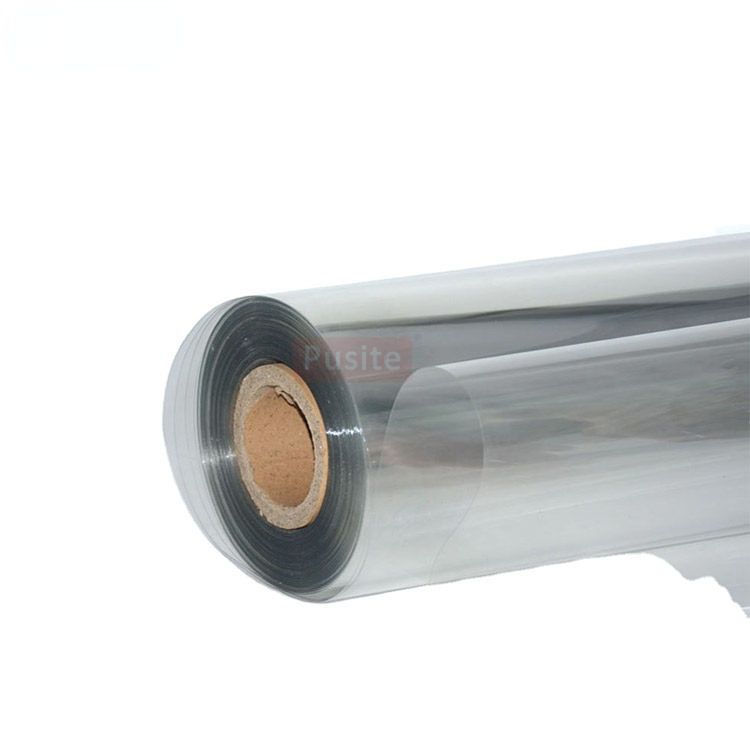

4. Thermoformability: 0.5mm PETG plastic sheet can be easily thermoformed, cut, and bent, making it versatile for different shapes and designs.

5. FDA Compliance: 0.5mm PETG plastic sheet is often FDA-approved for food contact, making it suitable for packaging and containers.

0.5mm PETG (Polyethylene Terephthalate Glycol) plastic sheet is a common packaging material known for its high transparency, strong toughness, and chemical resistance. Here are some common application areas:

1. Electronics Packaging: Used for packaging phones, tablets, laptops, and other electronic products, providing transparent protection and easy display.

2. Food Packaging: PETG plastic sheet has good food safety properties, making it suitable for packaging fruits, vegetables, pastries, and other food items, ensuring freshness and hygiene.

3. Medical Device Packaging: PETG's non-toxicity and transparency make it suitable for packaging medical devices and pharmaceuticals, facilitating inspection of the contents.

4. Cosmetics Packaging: High transparency and glossiness make it ideal for packaging cosmetics and skincare products, enhancing product appeal.

5. Stationery and Gift Packaging: PETG plastic sheets are used for making stationery and gift boxes, which are both aesthetically pleasing and protective.

6. Toy Packaging: Used for packaging toys, allowing product display while preventing dust and damage.

7. Tool and Component Packaging: Used for packaging various small tools and components, offering protection and easy display.

8. Clothing and Accessories Packaging: Used for packaging clothing, belts, scarves, and other items, with transparent packaging to showcase product details.

Storing 0.5mm PETG plastic sheets properly is essential to maintain their quality and usability. Here are some guidelines for storing PETG plastic sheets:

1. Storage Environment

Temperature: Store 0.5mm PETG plastic sheets in a cool, dry place with a stable temperature. Avoid areas with extreme temperatures or fluctuations, ideally between 10°C to 25°C (50°F to 77°F).

Humidity: Maintain low humidity levels to prevent moisture absorption, which can lead to warping or other deformations.

2. Storage Position

Flat Storage: Store the 0.5mm PETG plastic sheets flat to prevent bending or warping. If flat storage is not possible, ensure the sheets are stored vertically with support to prevent sagging.

Support: Use flat, smooth surfaces and avoid sharp edges or objects that could damage the sheets.

3. Protection from Elements

Sunlight: Keep 0.5mm PETG plastic sheets out of direct sunlight to prevent UV degradation, which can cause yellowing or brittleness over time.

Dust and Dirt: Cover the sheets with a protective layer, such as a plastic film or a clean cloth, to keep them free from dust and debris.

4. Handling

Clean Hands: Always handle PETG sheets with clean hands or wear gloves to avoid transferring oils, dirt, or fingerprints onto the surface.

Careful Handling: Avoid dragging the sheets across surfaces to prevent scratches. Lift and move them carefully.

5. Stacking

Limited Height: If stacking is necessary, do not stack too high to avoid excessive weight that could cause deformation. Use interleaving materials like soft foam or cardboard between sheets to prevent scratching.

6. Labeling

Identification: Clearly label stored PETG sheets with relevant information such as thickness, dimensions, and date of purchase to ensure proper inventory management and easy identification.

7.Ventilation

Air Circulation: Ensure good ventilation in the storage area to avoid buildup of fumes or odors, especially if the sheets are newly manufactured or have been recently cut.

|

Product Name |

0.5mm PETG Plastic Sheet |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.