Material Composition:

HIPS PlasticPrice Range:

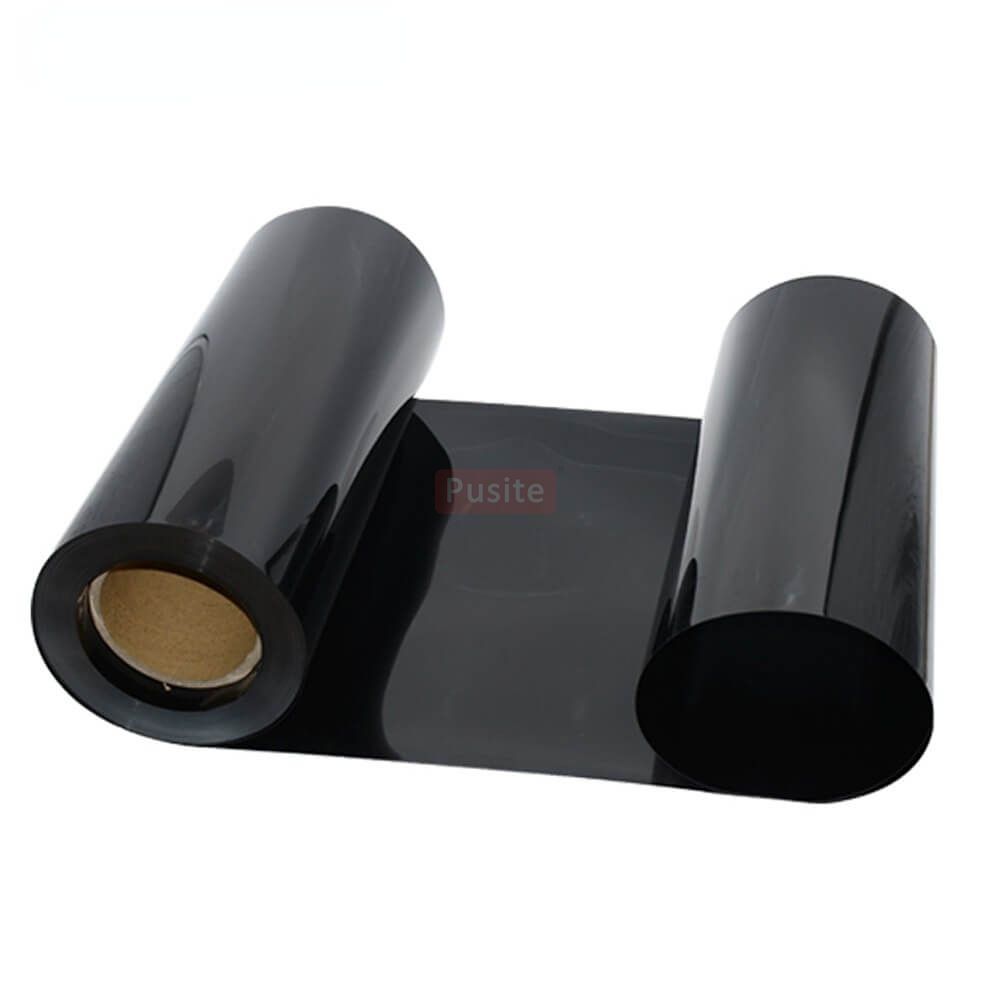

$1.28-$1.92/kgAntistatic HIPS plastic rolls are typically modified with additives that help dissipate static electricity rather than allowing it to build up on the surface. Antistatic HIPS plastic rolls factory Shanghai Pusite has a large numberr of high quality plastic conductive HIPS plastic rolls for sale online, you can get same free samples for quality check before placing an bulk order. Shanghai Pusite is one great China HIPS plastic roll manufacturer and supplier. if you want to find a professional and responsible HIPS film roll supplier in China, Shanghai Pusite will be your great choice!

High Impact Polystyrene (HIPS) plastic rolls that are antistatic are often used in various applications where static electricity buildup needs to be minimized or controlled. Here are some key points about antistatic HIPS plastic rolls:

Material Composition: Antistatic HIPS plastic rolls are typically modified with additives that help dissipate static electricity rather than allowing it to build up on the surface.

Applications: They are used in packaging materials, electronic components trays, and other applications where static electricity can damage sensitive electronics or attract dust and particles.

Properties: These rolls maintain the mechanical and physical properties of standard HIPS, such as impact resistance and ease of processing, while also providing antistatic properties.

Handling: When using antistatic HIPS rolls, it's important to handle them properly to maintain their antistatic effectiveness, such as avoiding excessive handling or exposure to contaminants that could reduce their antistatic properties.

Antistatic HIPS plastic rolls offer several benefits, making them a popular choice in various industries. Here are some of the key benefits:

Enhanced Safety: Reduced risk of static discharge, which can ignite flammable materials.

Improved Cleanliness: Less dust and particulate attraction, maintaining cleaner surfaces.

Increased Efficiency: Reduced sticking and clinging during manufacturing processes.

Better Product Protection: Protects sensitive electronic components from ESD damage.

Regulatory Compliance: Meets industry standards for static control in specific applications.

Cost-Effective: Antistatic HIPS plastic roll is generally more affordable compared to other engineering plastics, making it a cost-effective choice for applications requiring static control and impact resistance.

Versatility: Antistatic HIPS plastic roll can be easily thermoformed, extruded, and fabricated, allowing for a wide range of shapes and sizes. This makes it adaptable for various packaging, housing, and component applications.

Chemical Resistance: Antistatic HIPS plastic roll offers good resistance to many chemicals, making it suitable for use in environments where it might come into contact with oils, acids, and other substances.

Antistatic HIPS plastic rolls are used in a variety of applications across different industries due to their unique properties. Here are some common applications:

Electronics Packaging: Antistatic HIPS is widely used for packaging sensitive electronic components such as circuit boards, semiconductors, and computer parts to prevent static discharge that can damage these components.

Trays and Containers: Used for manufacturing trays and containers that store and transport electronic devices and components, ensuring protection against static buildup.

Consumer Electronics: Utilized in the production of housings and cases for various consumer electronics, including smartphones, tablets, and laptops packing.

Display Packaging: Employed in packaging for retail products, especially those that include electronic components, providing both protection and an attractive presentation.

Industrial Applications: Used for making parts and components in industrial machinery that need to be protected from static electricity packing.

Pharmaceutical Packaging: Applied in the packaging of pharmaceutical products where static control is necessary to prevent contamination and ensure product integrity.

Food Industry: Used in certain food packaging applications where static control is needed to prevent dust and particles from contaminating the product.

These applications highlight the versatility and importance of antistatic HIPS plastic rolls in various sectors, especially where static electricity poses a risk to product quality and safety.

Proper storage of antistatic HIPS plastic rolls is crucial to maintaining their quality and functionality. Here are some best practices for storing antistatic HIPS plastic rolls:

Cool, Dry Environment: Store the rolls in a cool, dry environment to prevent moisture absorption and degradation of the material. Ideal storage temperatures are typically between 10°C and 30°C (50°F to 86°F).

Avoid Direct Sunlight: Keep the rolls away from direct sunlight and UV light exposure, as UV radiation can cause the material to degrade over time.

Clean Storage Area: Ensure the storage area is clean and free from dust, dirt, and other contaminants that could compromise the antistatic properties of the rolls.

Humidity Control: Maintain a controlled humidity level, ideally below 50%, to prevent moisture absorption which can affect the material's properties.

Flat Surface Storage: Store the rolls on a flat surface or on proper storage racks designed to hold rolls. This prevents deformation or damage to the rolls.

Avoid Heavy Loads: Do not stack heavy objects on top of the rolls to prevent crushing or deforming the material.

Protection from Chemicals: Keep the rolls away from chemicals, solvents, and other corrosive substances that could react with the plastic.

Proper Labeling: Clearly label the rolls with relevant information, such as material type, antistatic properties, and production date, to ensure proper identification and usage.

Rotate Stock: Use a first-in, first-out (FIFO) inventory system to ensure that older rolls are used before newer ones, minimizing the risk of material degradation over time.

Packaging: Keep the rolls in their original packaging until ready for use to provide an extra layer of protection against environmental factors.

By following these storage guidelines, you can ensure that antistatic HIPS plastic rolls maintain their properties and remain in optimal condition for use in various applications.

|

Product Name |

Antistatic HIPS plastic roll |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.