Material Composition:

PET plasticPrice Range:

$1.25-$1.89/kgClear PET plastic rolls offer a combination of transparency, durability, recyclability, chemical resistance, and cost-effectiveness, making them a preferred choice for packaging various products across industries.

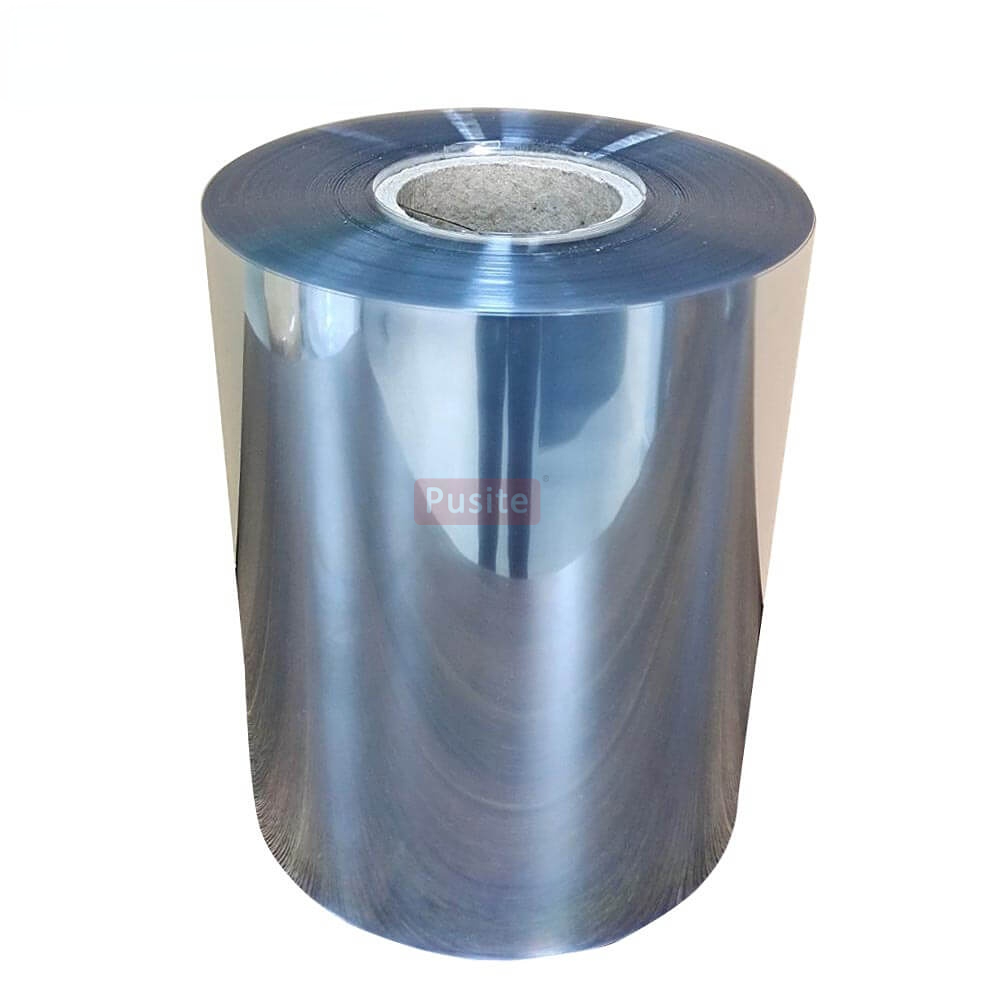

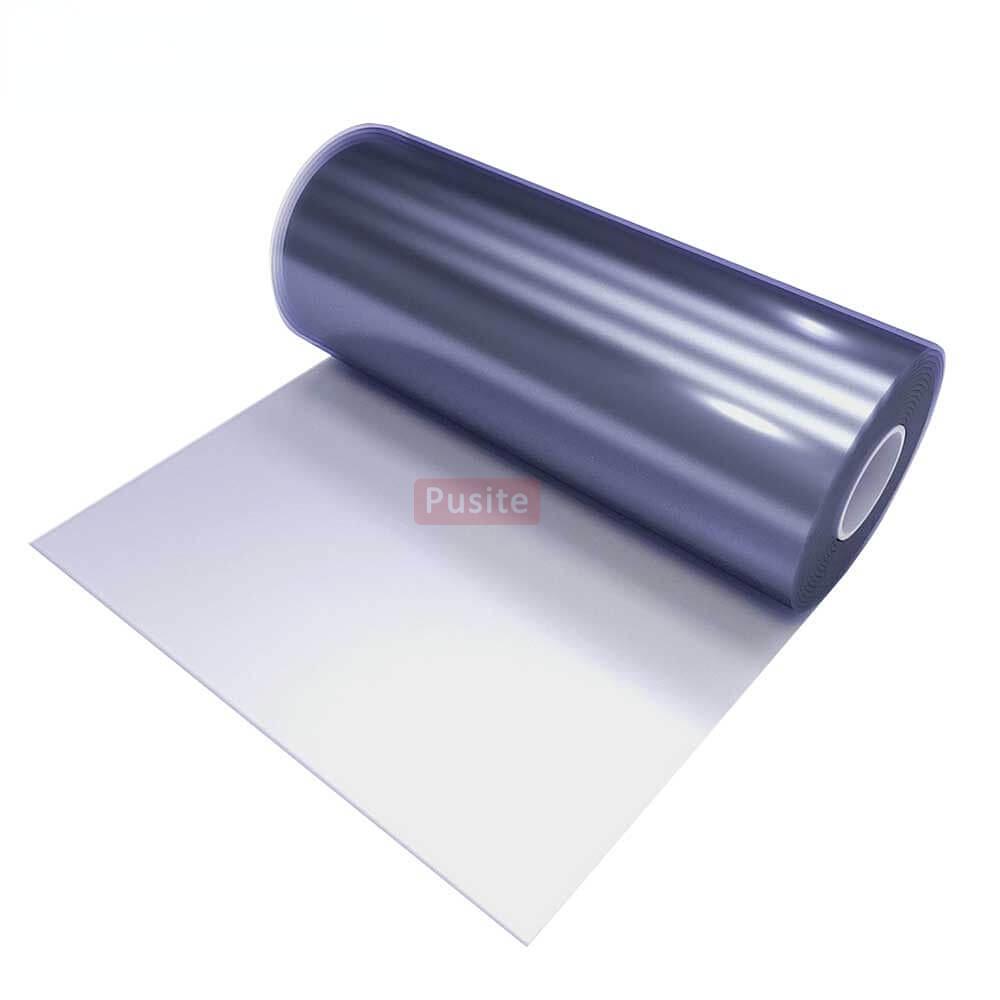

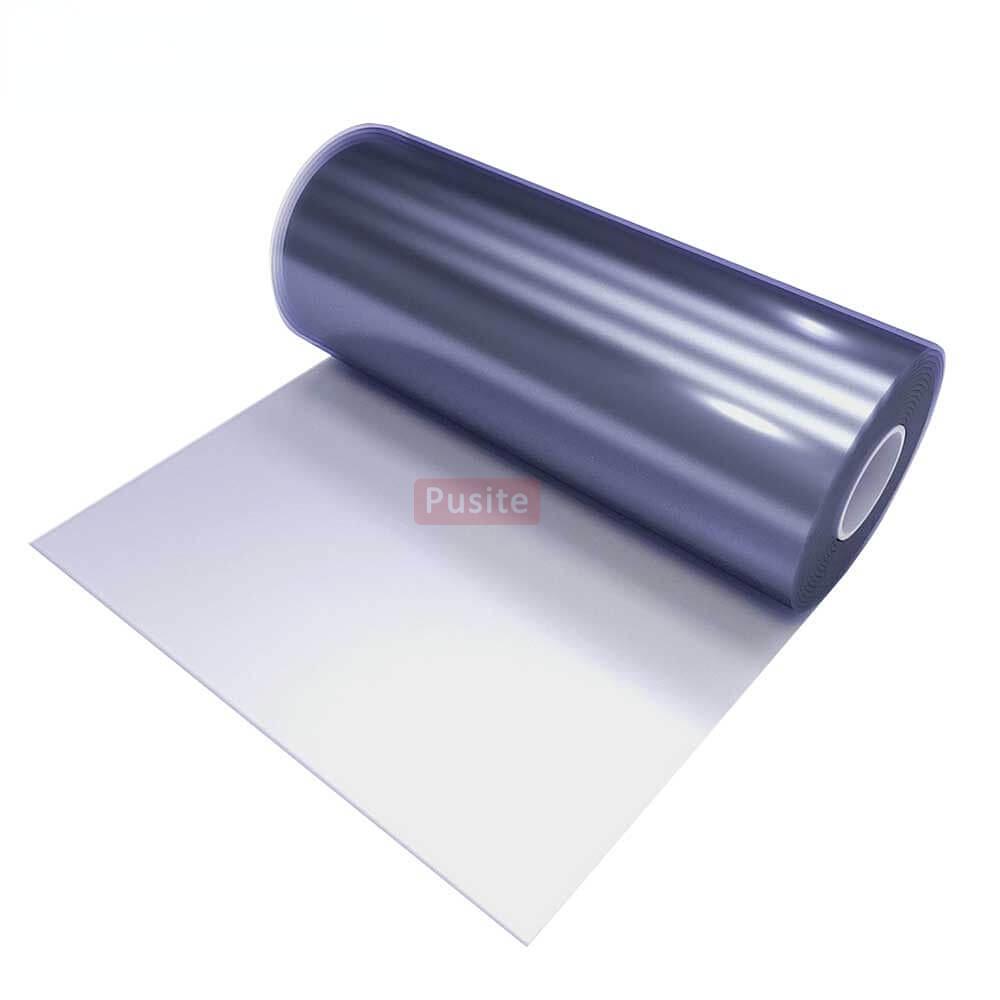

Clear PET plastic roll typically refers to a roll of plastic film made from PET (Polyethylene Terephthalate) material that is transparent or clear in appearance. Clear PET plastic rolls is commonly used in various packaging applications due to its clarity, strength, and recyclability.

Clear PET plastic rolls are often used in industries such as food packaging, where transparency is important for displaying products while providing protection from external elements. Clear PET plastic rolls may also find applications in other sectors such as manufacturing, printing, and agriculture.

Clear PET plastic rolls are available in various thicknesses and widths to suit different packaging needs. Additionally, clear PET plastic rolls may be used for creating labels, laminates, or other flexible packaging solutions.

|

|

| Name | Clear PET Plastic Rolls |

| Category | PETG, APET, GAG,RPET |

| Brand | PULIXIN |

| Certificate | Certificate SGS, ROHS, ISO, TDS, MSDS, etc. |

| Origin | China |

| Color | Transparent/ Custom colors |

| Width | 300-1400 mm |

| Thickeness | 0.18-1.0 mm |

| Length | No limit |

| Weight per roll | 50-200 kg or customized |

| MOQ | 500 kg |

| Monthly production | 3000-5000 tons |

| Delivery Methods | Ocean shipping, air transportation, express, land transportation. |

| Global market | Europe, South America, North America, Europe, Central Asia, Southeast Asia, South Asia, Middle East, Australia, etc. |

| Payment Term | Payment Term Credit card, T/T, L/C, Western Union, Paypal. |

Clear PET plastic roll have a wide range of applications across various industries due to their transparency, durability, and versatility. Some common applications include:

1. Food Packaging: Clear PET plastic rolls are commonly used for packaging food products such as fresh produce, bakery items, confectionery, snacks, and dairy products. They offer excellent visibility of the contents, ensuring that consumers can see the quality and freshness of the food.

2. Beverage Packaging: Clear PET plastic rolls are extensively used for packaging beverages such as water, soft drinks, juices, sports drinks, and alcoholic beverages. PET bottles made from clear plastic rolls provide a lightweight and shatter-resistant packaging solution for liquid products.

3. Personal Care and Cosmetics: Clear PET plastic rolls are used to create packaging for personal care products such as shampoo, conditioner, body wash, lotions, and skincare products. The transparent packaging allows consumers to see the color and consistency of the product.

4. Pharmaceutical Packaging: Clear PET plastic rolls are suitable for packaging pharmaceutical products such as tablets, capsules, syrups, and ointments. PET containers offer a combination of durability and chemical resistance, ensuring the integrity of the medication.

5. Household Products: Clear PET plastic rolls are used for packaging various household products such as cleaning agents, detergents, air fresheners, and pet care products. The transparent packaging allows consumers to easily identify the product and its usage instructions.

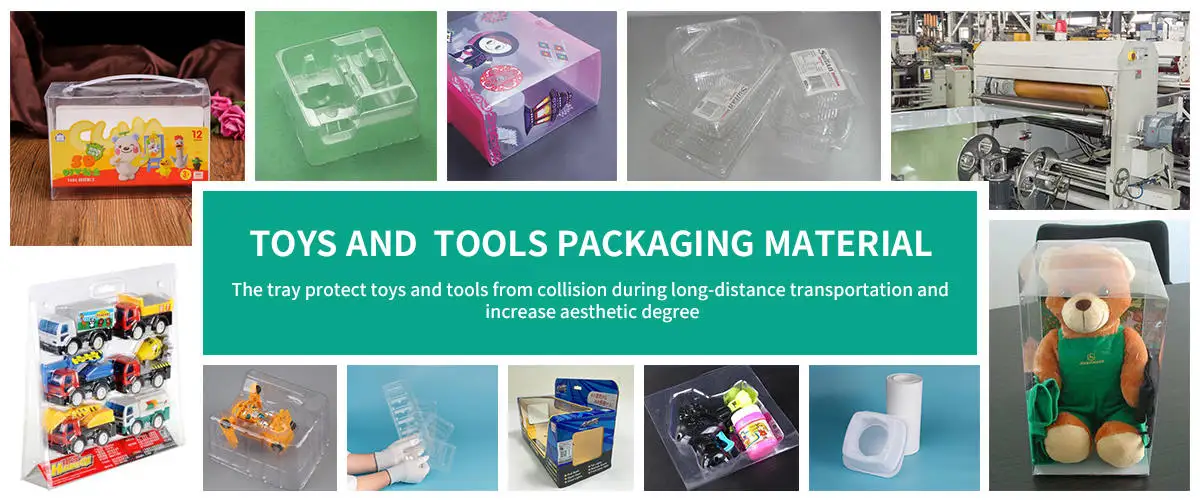

6. Retail Packaging: Clear PET plastic rolls are used to create retail packaging for a wide range of products sold in supermarkets, convenience stores, and retail outlets. They can be converted into clamshells, trays, blister packs, and display boxes to showcase products effectively on store shelves.

7. Electronics Packaging: Clear PET plastic rolls are used for packaging electronic products such as mobile phone accessories, computer peripherals, and small appliances. PET packaging provides protection against dust, moisture, and impact during shipping and handling.

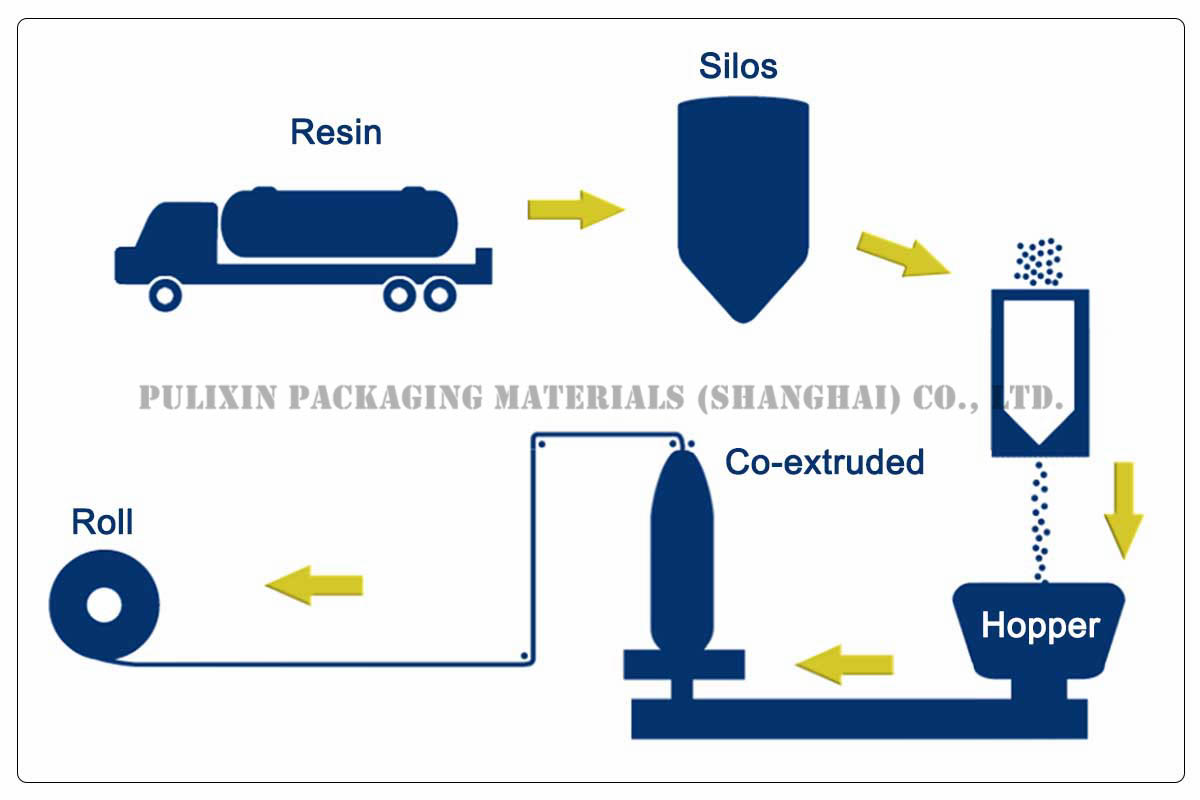

The production of clear PET plastic roll usually involves the following steps:

1. Raw material preparation: First, PET resin needs to be prepared as raw material. PET resin is usually supplied in pellet or pellet form and can include additives to improve its properties such as reinforcing agents, antioxidants, etc.

2. Extrusion: During the extrusion process, the PET resin is heated to its melting point and then extruded through an extruder into a film or sheet shape. This extrusion process involves pressing molten PET plastic through a die into a film of the desired width and thickness.

3. Cooling and solidification: The extruded clear PET plastic roll enters the cooling area, where it is cooled and solidified to ensure that it maintains the desired shape and size.

4. Cutting and Rewinding: Once the clear PET plastic roll have cooled and solidified, they are cut to the desired length and then rolled into rolls. This can be done with automatic or semi-automatic cutting and coiling machines.

5. Quality Control and Packaging: During the production process, quality control is very important. This includes checking the Clear PET plastic roll thickness, width, transparency and any possible defects. Once the rolls are confirmed to meet the requirements, they will be packaged into rolls or other forms for easy transportation and storage.

Choosing the right clear PET plastic roll involves considering several factors to ensure it meets your specific requirements. Here's a guide to help you make an informed decision:

1. Application Requirements: Determine the specific application for which you need the clear PET plastic roll. Consider factors such as whether it will be used for food packaging, beverage packaging, personal care products, pharmaceuticals, or other industrial applications.

2. Size and Dimensions: Consider the dimensions of the clear PET plastic roll required for your packaging needs. Determine the width, length, and thickness of the roll based on the size and quantity of products you intend to package.

3. Clarity and Transparency: Evaluate the clarity and transparency of the PET plastic roll. Opt for a roll that offers high optical clarity and transparency to showcase the contents of the packaging effectively.

4. Durability and Strength: Assess the durability and strength of the PET plastic roll. Ensure that it offers sufficient tensile strength, puncture resistance, and impact resistance to protect the packaged products during handling, shipping, and storage.

5. Chemical Compatibility: Consider the chemical compatibility of the clear PET plastic roll with the contents of the packaging. Ensure that the roll is suitable for use with food products, beverages, pharmaceuticals, or other chemicals without compromising the integrity of the packaging or the safety of the contents.

6. Recyclability: Check if the clear PET plastic roll is recyclable. Opt for rolls made from recyclable PET material to minimize environmental impact and support sustainability efforts.

7. Regulatory Compliance: Ensure that the clear PET plastic roll complies with relevant regulatory standards and guidelines, such as FDA (Food and Drug Administration) regulations for food contact materials or regulations governing pharmaceutical packaging.

8. Supplier Reputation and Quality Assurance: Choose a reputable supplier known for providing high-quality clear PET plastic rolls. Verify the supplier's certifications, quality control processes, and track record to ensure consistency and reliability in product performance.

9. Cost Considerations: Compare the cost of different clear PET plastic roll while considering factors such as quality, performance, and suitability for your application. Balance cost considerations with the desired quality and performance requirements to make a cost-effective choice.

10. Customization Options: Determine if customization options are available for the clear PET plastic roll, such as custom widths, lengths, thicknesses, printing, or embossing. Customized rolls can meet specific packaging requirements and enhance branding and product presentation.

|

Product Name |

Clear PET plastic roll |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.