Material Composition:

HIPS PlasticPrice Range:

$1.28-$1.92/kgWholesale double color HIPS plastic sheet roll from the leading plastic HIPS sheet factory Pusite in China. Pusite owns 39 patents, covers 6000 square meters HIPS sheet workshop, can make 5000 metric tons black HIPS sheets within one month to meet your urgent large quantity requirement at the peak season. Because of our exclusive and advanced technology, Pusite can be able to produce high quality Double color HIPS plastic sheet roll effectively and cost-saving. You can save much product cost and gain much more business profit if you do business with us. Pusite always put the quality at the first place, use only 100% virgin HIPS raw material to make sure all kinds of HIPS sheets feature high quality. Pusite always pursuit for spreading high value to global clients and getting a great long-term win-win cooperation, so please feel free to let us know if you are interested in our products.

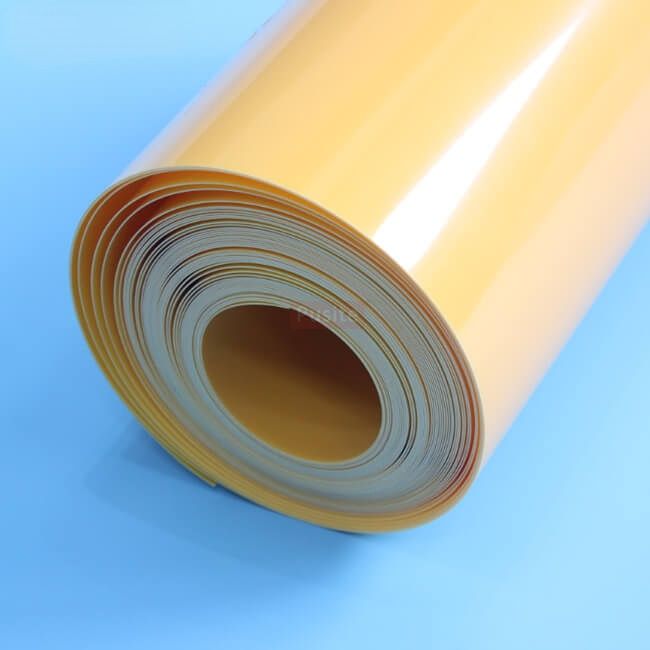

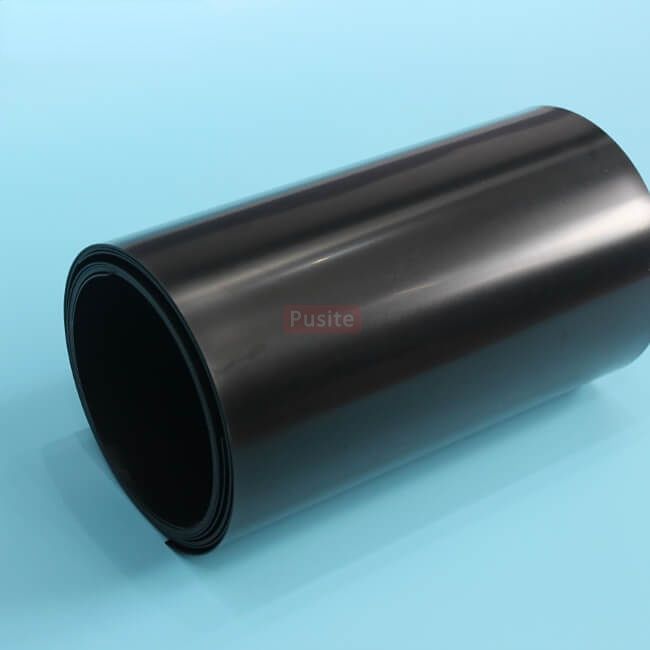

Double Color HIPS (High Impact Polystyrene) Plastic Sheet Roll is a versatile material created by co-extruding two layers of HIPS in different colors.

This dual-color design not only enhances the aesthetic value of the material but also retains the high impact strength and flexibility that HIPS is known for. It is lightweight, easy to form, and offers excellent dimensional stability, making it ideal for various packaging and thermoforming applications.

Some key features of double color HIPS plastic sheet rolls include:

1. High Impact Resistance: Double color HIPS plastic sheet rolls provides excellent durability and resistance to impact, making it suitable for products that require strength and flexibility.

2. Aesthetic Appeal: The dual-color feature enhances the visual appearance, making it ideal for packaging applications where presentation is important.

3. Easy Thermoforming: Double color HIPS plastic sheet roll is well-known for its ease of thermoforming, making it popular in industries like food packaging, electronics, and medical devices.

4. Applications: Commonly used in packaging, trays, clamshells, and other products that require both functional protection and aesthetic value.

Double Color HIPS plastic sheet rolls are widely used in various product packaging due to their excellent strength, impact resistance, and dual-color design. Below are some typical applications:

1. Food Packaging

Food Trays: Double Color HIPS plastic sheet rolls are commonly used to make food trays, enhancing visual appeal, and suitable for fast food, pastries, and refrigerated food packaging.

Takeout Boxes: These sheets can be used for takeout food packaging, providing protection while adding visual appeal with different colors.

Blister Packaging: Used in food blister packaging, such as for fruits, vegetables, and ready-to-eat meals, ensuring both safety and attractiveness.

2. Electronics Packaging

Electronic Accessories Packaging: The dual-color design enhances product appearance, suitable for blister packaging of items like earphones, USB cables, and phone accessories.

Appliance Casings and Protective Covers: Double Color HIPS plastic sheet roll Provides a durable and eye-catching packaging solution for small appliances or consumer electronics.

3. Cosmetics and Personal Care Products Packaging

Cosmetic Trays: Ideal for packaging perfumes, skincare products, and makeup tools, offering protection and enhancing a premium look.

Gift Boxes: The dual-color design is used for high-end gift boxes, drawing customer attention and adding brand value.

4. Toys and Gift Packaging

Toy Blister Packaging: Double Color HIPS plastic sheet roll is used for toy blister packaging, such as for models, building blocks, and electronic toys, enhancing product display.

Gift Boxes: Suitable for custom gift boxes or display packaging, adding design sophistication and premium quality.

5. Medical Device Packaging

Medical Equipment Trays: The dual-color design can be used for packaging various medical devices, such as syringes and surgical instruments, ensuring hygiene and making differentiation and management easier.

6. Stationery Packaging

Stationery Blister Packaging: Ideal for packaging stationery items like pens, rulers, erasers, and staplers, where the dual-color design enhances the packaging’s appeal.

These applications demonstrate the broad use of double color HIPS plastic sheet roll in the packaging industry, improving both aesthetics and functionality.

Double Color HIPS (High Impact Polystyrene) plastic sheet rolls offer several advantages, making them popular for various applications. Here are some key benefits:

1. Aesthetic Appeal: The two-tone design allows for creative and attractive products, enhancing visual appeal in displays, signage, and packaging.

2. Durability: Double Color HIPS Plastic Sheet Roll is known for its high impact resistance, making the sheets robust and less prone to cracking or breaking under stress.

3. Lightweight: Double Color HIPS Plastic Sheet Rolls are lightweight, which facilitates easy handling and reduces shipping costs.

4. Versatile Processing: These sheets can be easily thermoformed, cut, and printed on, allowing for a wide range of applications in industries such as packaging, advertising, and construction.

5. Chemical Resistance: Double Color HIPS Plastic Sheet Rolls offers good resistance to various chemicals, making it suitable for use in environments where exposure to substances might occur.

6. Cost-Effectiveness: Double color HIPS sheets are generally more affordable than other materials with similar properties, providing a cost-effective solution for businesses.

7. Recyclability: HIPS is recyclable, contributing to environmental sustainability and allowing for the reuse of materials.

8. UV Stability: Many Double Color HIPS Plastic Sheet Rolls are treated to be UV-resistant, ensuring that they maintain their appearance and structural integrity when exposed to sunlight.

These advantages make double color HIPS plastic sheet rolls a preferred choice in various sectors, including retail, construction, and packaging.

The production process for double color High Impact Polystyrene (HIPS) plastic sheet rolls involves several key steps. Here’s a concise overview:

1. Raw Material Preparation

Polymer Selection: High Impact Polystyrene (HIPS) is chosen as the primary material. Colorants and additives are prepared based on the desired colors and properties.

Color Masterbatch: A color masterbatch is created by mixing HIPS with pigments and additives, ensuring uniform color distribution.

2. Extrusion Process

Extruder Setup: The prepared HIPS and color masterbatch are fed into an extruder. The extruder uses heat and mechanical shear to melt the polymers and mix them thoroughly.

Die Configuration: A specialized die is designed to produce a double-color sheet. This can involve a co-extrusion process where two different colors of HIPS are extruded simultaneously to form a layered sheet.

3. Cooling and Solidification

Cooling: The molten HIPS sheet is passed through a cooling system, often using water baths or air cooling to solidify the material.

Thickness Control: The sheet thickness is monitored and adjusted during the cooling process to meet specifications.

4. Cutting and Trimming

Sheet Cutting: Once cooled and solidified, the HIPS sheets are cut into the desired roll lengths and widths.

Edge Trimming: Edges may be trimmed to ensure uniformity and eliminate any imperfections.

5. Quality Control

Inspection: The double color sheets undergo quality checks to ensure they meet color consistency, thickness, and other physical properties.

Testing: Samples may be tested for impact resistance, flexibility, and other mechanical properties.

6. Packaging and Storage

Roll Formation: The finished double color HIPS sheets are rolled onto cores for easier handling and transportation.

Packaging: The rolls are packaged to protect them during storage and shipping, ensuring they remain free from damage and contamination.

This process can vary slightly depending on specific manufacturing capabilities and the desired final product characteristics.

|

Product Name |

Double Color HIPS Plastic Sheet Roll |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.