Material Composition:

HIPS PlasticPrice Range:

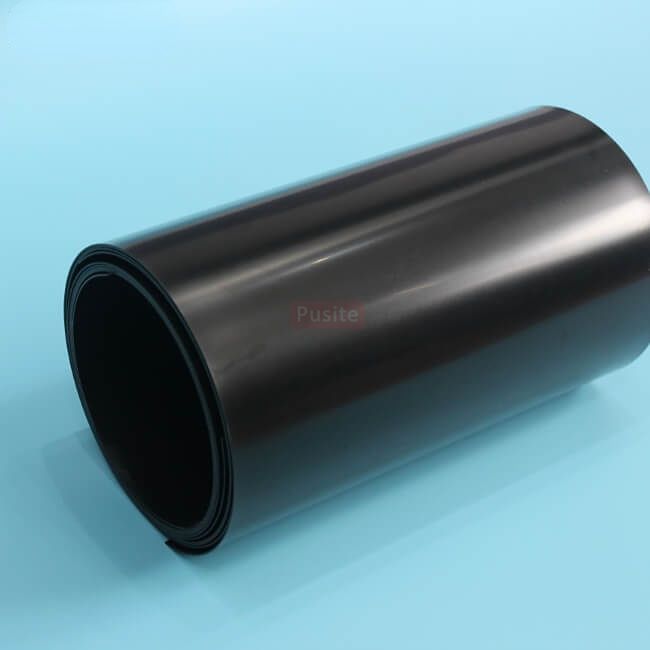

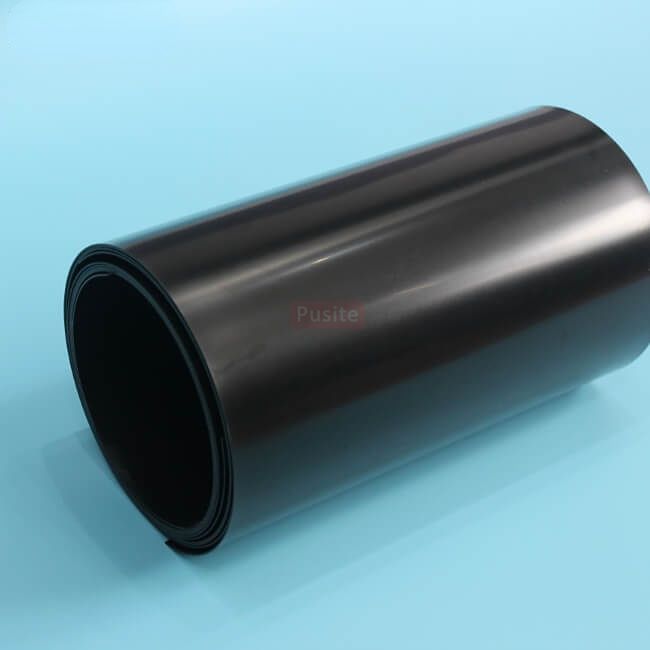

1.25-1.89$Double-sided bright HIPS plastic sheet rolls Purchase large quantities of high-quality double-sided bright HIPS plastic sheet rolls from Pusite, one of the largest HIPS sheet factories in China. Pusite was founded in 2009 and is located in Shanghai, China, specializing in the production and sales of many different types of HIPS plastic sheet rolls With more than 10 years of domestic and international sales experience. Pusite has now established a good reputation in the global HIPS sheet trading market. More than one hundred global customers have established good win-win cooperation relationships with Pusite, and many internationally renowned companies such as Apple regard Pusite as an excellent Chinese partner. If you want to know more about our products and services, please feel free to let us know, we will do our best to serve you and achieve mutual benefit and win-win results together.

Double-sided bright HIPS (High-Impact Polystyrene) plastic sheet rolls are versatile and durable materials widely used in various industries. Known for their exceptional impact resistance, these sheets offer a combination of strength and lightweight properties, making them ideal for both indoor and outdoor applications.

1. Durability: Double-sided bright HIPS (High-Impact Polystyrene) plastic sheet rolls are renowned for its toughness and resistance to impacts, making these sheets suitable for demanding environments.

2. Aesthetic Appeal: The bright surface finish provides a visually appealing look, making them suitable for applications where appearance matters.

3. Lightweight: These sheets are lightweight, which facilitates easy handling and installation, reducing transportation costs.

4. Versatility: Double-sided bright HIPS (High-Impact Polystyrene) plastic sheet rolls can be used in various applications, including signage, displays, packaging, and protective coverings.

5. Easy to Fabricate: They can be easily cut, formed, and printed on, allowing for customization to meet specific requirements.

6. Chemical Resistance: Double-sided bright HIPS (High-Impact Polystyrene) plastic sheet rolls are resistant to a variety of chemicals, making these sheets suitable for use in environments where exposure to solvents or cleaning agents is common.

Double-sided bright HIPS plastic sheet rolls are an excellent choice for businesses looking for a reliable and attractive material for various applications. Their combination of durability, lightweight nature, and aesthetic qualities make them a preferred choice in multiple industries.

The production process of Double-sided bright HIPS plastic sheet rolls mainly includes the following steps:

1. Raw material preparation: polystyrene resin, plasticizer, stabilizer and other raw materials are mixed evenly in a certain proportion to make polystyrene resin.

2. Extrusion molding: the prepared polystyrene resin is heated and melted, and extruded into a continuous sheet through an extruder.

3. Cooling and shaping: the extruded sheet is quickly cooled by a cooling water bath or air cooling to shape it.

4. Surface treatment: in order to achieve the effect of double-sided bright, both sides of the sheet need to be treated. Common surface treatment methods are:

| Product Name | HIPS plastic sheet roll |

|---|---|

| Material | HIPS vacuum forming material , 100% raw material |

| Color | Transparent,black,green or any customized color |

| Thickness Tolerance | According to GB (higher than GB) |

| Application | Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

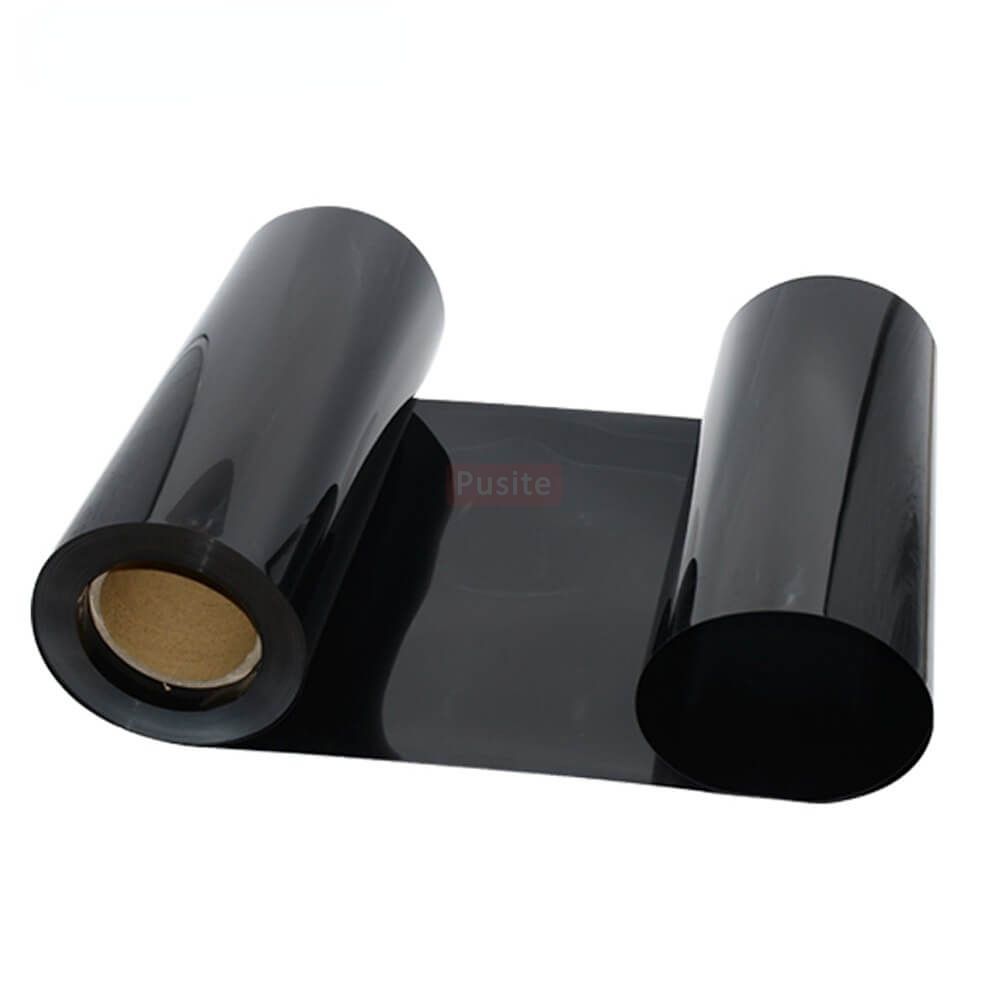

| Width | 300~1400mm or Customized |

| Thickness | 0.15~3mm or Customized |

| Special Treatment | Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive. |

| Features | 1.High temperature resistance, not easily melted 2.Easy to peel off and no residue requirement 3.Printable, good inking effect 4.Widely used in food and drug industry 5.Uniform thickness, smooth surface/beautiful sand ripples 6.No grains, contamination control and good processing performance |

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping ,air transportation, express,land transportation |

| Payment Term | Credit card ,T/T,L/C,Western Union,Paypal |

| Mass Production Lead Time | 3-15 days depend on order quantity |

| Certificate | ROHS,MSDS,TDS,SGS,ISO9001 |

| Core Diameter | 3 inch or 6 inch depend on customer requirement |

| Packing | Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet for each roll |

The realization of double-sided bright HIPS plastic sheet rolls mainly relies on the following aspects:

1. Purity and uniformity of resin: High-purity and uniform resin can reduce impurities and bubbles, ensure the uniformity of the internal structure of the sheet, and thus improve the surface brightness.

2. Control of extrusion process parameters: By controlling the temperature, pressure, screw speed and other parameters of the extruder, the fluidity of the melt and the thickness of the sheet can be adjusted, thereby affecting the surface quality of the sheet.

3. Cooling speed: Rapid cooling can reduce grain growth and improve the transparency and glossiness of the sheet.

4. Choice of surface treatment process: Different surface treatment processes are suitable for different sheets and different surface effect requirements.

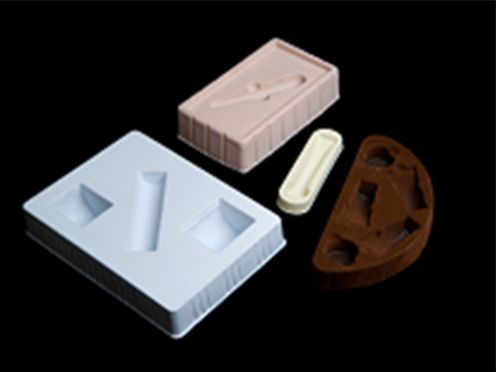

Double-Sided bright HIPS plastic sheet rolls is widely used in the packaging of various products due to its superior properties and beautiful appearance. Here are some common application areas:

1. Food packaging: Used in the packaging of products such as cakes, candies, chocolates, etc. to ensure the freshness of the products and attract consumers.

2. Cosmetic packaging: Commonly used in the packaging of skin care products, makeup and perfumes, providing protection while enhancing the appearance of the products.

3. Electronic product packaging: Suitable for the packaging of small electronic devices and accessories, providing good protection and display effects.

4. Toy packaging: Used for the packaging of various toys, providing protection while attracting children's attention.

5. Gift packaging: Making gift boxes and packaging, adding beauty and enhancing the overall image of gifts.

6. Pharmaceutical packaging: Used in the packaging of medicines and health products to ensure the safety and stability of the products.

7. Daily necessities packaging: Used in the packaging of household cleaning products and personal care products, providing practicality and attractiveness.

8. Stationery product packaging: Suitable for the packaging of stationery and office supplies to keep the products neat and presentable.

| Sheet type | Width mm | Thickness mm | Color | Resistance value Ω |

|---|---|---|---|---|

| HIPS normal sheet | 200-800 | 0.3-2 | Any | / |

| High impact HIPS | Any | / | ||

| HIPS black conductive | 200-800 | 0.3-2 | Black | 10^4-10^6 |

| HIPS black semi-conductive | Black | 10^6-10^9 | ||

| HIPS black volume conductive | Black | 10^4-10^6 | ||

| HIPS polymer sheet | Any | 10^8 | ||

| HIPS anti-static sheet | Any | 10^9-10^11 | ||

| HIPS coated sheet | Any | 10^3-10^9 |

|

Product Name |

Double-sided bright HIPS plastic sheet rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.