Material Composition:

HIPS PlasticPrice Range:

$1.28-$1.92/kgFood Grade HIPS (High Impact Polystyrene) Plastic Roll for Thermoforming refers to a type of plastic material that is specifically designed and certified for use in food packaging and related applications.

Food Grade HIPS (High Impact Polystyrene) Plastic Roll for Thermoforming refers to a type of plastic material that is specifically designed and certified for use in food packaging and related applications.

1. Material Composition: HIPS is a form of polystyrene that has been modified to improve its toughness and impact resistance. It is commonly used in food-grade applications due to its ability to maintain food safety and hygiene standards.

2. Food Grade Certification: This type of HIPS plastic undergoes specific certifications and testing to ensure that it meets regulatory requirements for direct contact with food. This includes considerations for toxicity, migration of substances, and overall safety.

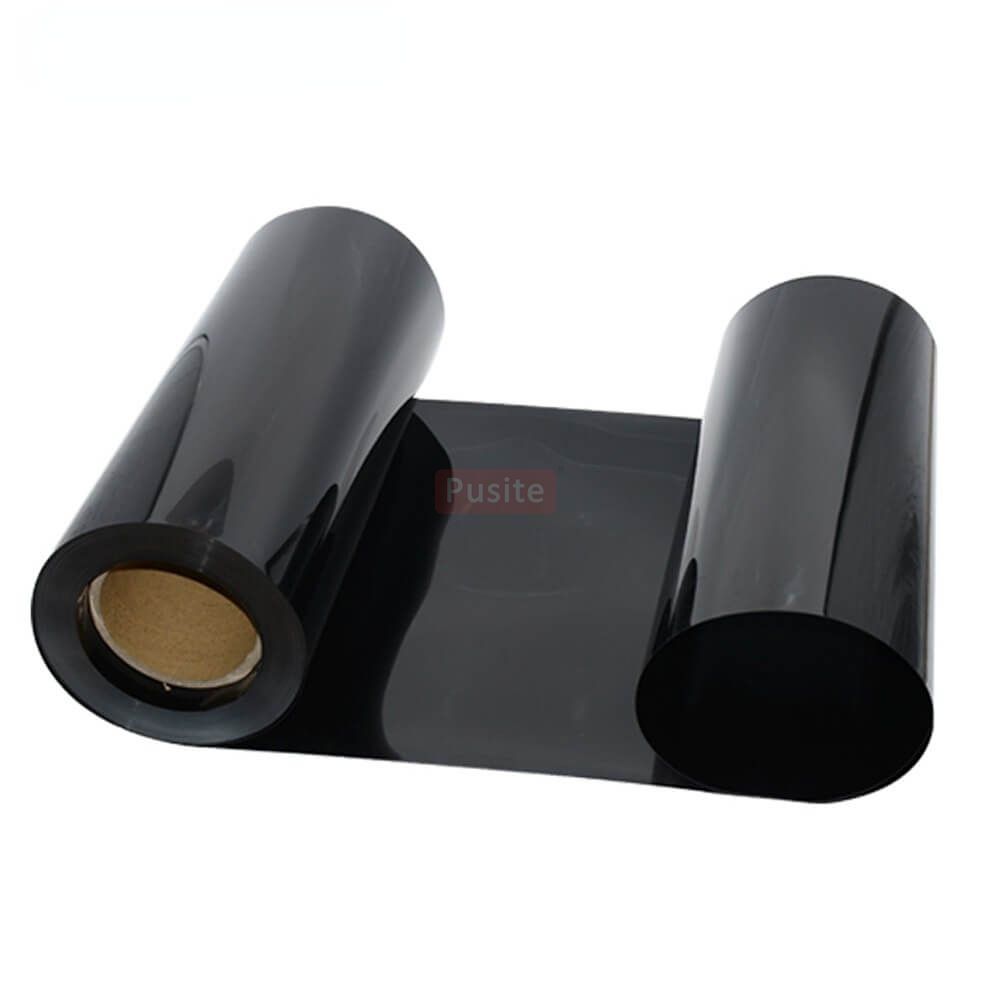

3. Roll Format: The plastic is typically supplied in roll form, which is convenient for thermoforming processes. Thermoforming involves heating the plastic sheet until it becomes pliable, then forming it into the desired shape using a mold.

4. Applications: Food Grade HIPS Plastic Rolls are used extensively in the food packaging industry for products such as trays, containers, clamshells, and lids. It is chosen for its combination of affordability, ease of processing, and suitability for food contact.

Food Grade HIPS Roll For Thermoforming

Overall, Food Grade HIPS Plastic Roll for Thermoforming ensures that the packaging used for food products maintains high standards of safety, hygiene, and compliance with food regulations.

Food Grade HIPS Plastic Roll for Thermoforming offers several advantages, making it a popular choice in the food packaging industry:

1. Impact Resistance: Enhanced toughness and durability, protecting food products during transportation and handling.

2. Cost-Effective: Generally more affordable compared to other food-grade plastics like PET or PVC, providing cost savings for manufacturers and consumers.

3. Thermoformability: Excellent processing characteristics, easily molded into various shapes and sizes, suitable for a wide range of packaging designs.

4. Lightweight: Reduces shipping and handling costs while maintaining structural integrity.

5. Good Barrier Properties: Provides an effective barrier against moisture and gases, helping to preserve the freshness and quality of food products.

6. Printable Surface: Can be easily printed on, allowing for high-quality branding, labeling, and product information.

7. Recyclability: HIPS is recyclable, contributing to sustainability efforts and reducing environmental impact.

8. Versatility: Suitable for a wide range of applications, including trays, clamshells, lids, and other types of food packaging.

9. Aesthetic Appeal: Offers a clean, professional look with options for various finishes and colors to enhance product presentation.

These advantages make Food Grade HIPS Plastic Roll for Thermoforming a preferred material for food packaging, balancing performance, cost, and safety.

Food Grade HIPS Plastic Roll for Thermoforming is widely used in various applications within the food packaging industry due to its beneficial properties. Some common applications include:

1. Food Trays: Used for packaging ready-to-eat meals, snacks, and fresh produce. These trays can be found in supermarkets, delis, and convenience stores.

2. Clamshell Packaging: Ideal for packaging sandwiches, salads, fruits, and baked goods. Clamshells provide an airtight seal and protect the contents from contamination and damage.

3. Lids and Covers: Used for sealing cups, bowls, and other food containers, ensuring freshness and preventing spills.

4. Dairy Containers: Suitable for yogurt, cheese, and other dairy products, providing a barrier against moisture and extending shelf life.

5. Meat and Poultry Packaging: Used for packaging fresh and processed meat products, offering durability and protection during transportation and storage.

6. Bakery Packaging: Ideal for packaging cakes, pastries, and other baked goods, maintaining freshness and providing an attractive display.

7. Frozen Food Packaging: Suitable for frozen meals, vegetables, and desserts, withstanding low temperatures without becoming brittle.

8. Confectionery Packaging: Used for packaging chocolates, candies, and other sweets, protecting them from damage and contamination.

9. Takeaway and Delivery Containers: Commonly used by restaurants and food delivery services for packaging takeaway meals, ensuring food remains secure and intact during transit.

10. Medical and Pharmaceutical Packaging: Though primarily used in food packaging, food grade HIPS can also be used in packaging medical and pharmaceutical products due to its safety and hygiene properties.

These applications highlight the versatility and practicality of Food Grade HIPS Plastic Roll for Thermoforming, making it a popular choice for a wide range of food packaging needs.

HIPS (High Impact Polystyrene) and PET (Polyethylene Terephthalate) are two commonly used plastics in food packaging. Here’s a comparison of their properties and applications:

| HIPS plastic rolls | PET plastic rolls |

| Advantages | |

| Cost-Effective: HIPS is generally cheaper than PET, making it a cost-effective option for many packaging applications. | High Clarity: PET is known for its excellent clarity and transparency, making it ideal for packaging that requires product visibility. |

| Impact Resistance: It has good impact resistance, which helps protect the contents during transportation and handling. | Superior Barrier Properties: PET has superior barrier properties against moisture, oxygen, and CO2, extending the shelf life of food products. |

| Thermoformability: HIPS is easy to thermoform into various shapes and sizes, making it versatile for different packaging needs. | Strength and Durability: PET is stronger and more durable than HIPS, providing better protection for the contents. |

| Lightweight: It is lightweight, reducing shipping costs. | Recyclability: PET is widely recyclable, which is a significant advantage in terms of environmental sustainability. |

| Good Barrier Properties: Provides a decent barrier against moisture and gases, helping to preserve the freshness of food products. | Chemical Resistance: PET offers better resistance to chemicals compared to HIPS. |

| Disadvantages | |

| Lower Barrier Properties: HIPS has lower barrier properties against oxygen and CO2 compared to PET, which can affect the shelf life of some products. | Cost: PET is generally more expensive than HIPS, which can increase packaging costs. |

| Less Transparent: HIPS is not as clear as PET, which may affect product visibility. | Thermoformability: While PET is thermoformable, it is more challenging to thermoform than HIPS and requires higher temperatures and more specialized equipment. |

| Heavier: PET is slightly heavier than HIPS, which may increase shipping costs. | |

| Applications in Food Packaging | |

| Food Trays: Commonly used for packaging ready-to-eat meals, snacks, and fresh produce. | Beverage Bottles: Widely used for water, soda, and other beverages due to its clarity and barrier properties. |

| Clamshell Packaging: Suitable for sandwiches, salads, fruits, and baked goods. | Clamshell Packaging: Ideal for salads, fruits, and bakery items where product visibility is important. |

| Lids and Covers: Used for sealing cups, bowls, and other food containers. | Thermoformed Containers: Used for various food packaging applications requiring high clarity and strong barrier properties. |

Both HIPS and PET have their unique advantages and disadvantages. The choice between the two depends on the specific requirements of the food packaging application, including cost, barrier properties, clarity, and recyclability. HIPS is favored for its cost-effectiveness and ease of thermoforming, while PET is preferred for its superior barrier properties and high clarity.

|

Product Name |

Food Grade HIPS Plastic Roll For Thermoforming |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.