Material Composition:

HIPS PlasticPrice Range:

$1.25-$1.89/kgWholesale high impact polystyrene sheet at competitive factory price from Shanghai Pusite. Shanghai Pusite is one great food grade plastic sheet roll manufacturer and supplier in China, owns 39 new product patents, 6000 square meters high impact polystyrene sheet production workshop, can supply at least 5000 metric tons output each month to meet your large quantity needs at the peak season. As the leading China high impact polystyrene sheet factory, Shanghai Pusite always put the high quality at the first place, only use 100% virgin high impact polystyrene sheet raw material. Meanwhile, Shanghai Pusite has exclusive and advanced high impact polystyrene sheet production technology and equipments, can be able to offer you very competitive cheap price based on the same quality in the market. So, if you want to find a reliable and professional food grade plastic sheet roll supplier in China, feel free to contact us, we can help you with your business!

Food Grade HIPS plastic sheet rolls are commonly used in food packaging due to their durability, transparency, and ability to meet food safety standards. They are typically FDA-approved or meet relevant regulatory requirements for food contact materials.

Key Features of Food Grade HIPS Plastic Sheet rolls

1. Non-toxic and Safe for Food Contact: Compliant with food safety regulations like FDA or EU standards.

2. Durability: High impact resistance, making them suitable for food packaging that requires strength and protection.

3. Ease of Processing: Food grade HIPS plastic sheet rolls can be thermoformed, printed on, and easily cut to the required dimensions.

4. Temperature Resistance: Suitable for a wide range of temperatures, though not ideal for high-heat applications.

5. Recyclability: Food grade HIPS plastic sheet rolls often recyclable, making it an environmentally friendly option.

Food Grade HIPS plastic sheet rolls have a variety of applications in the food industry due to their versatility, impact resistance, and ability to maintain food safety standards. Here are some of the key applications:

1. Food Packaging

Trays and Containers: Food grade HIPS plastic sheet rolls are commonly used to produce trays and containers for pre-packaged foods like fruits, vegetables, meats, and bakery products. Their clarity helps to present the food attractively.

Clamshell Packaging: This type of packaging is popular for fresh produce, sandwiches, snacks, and bakery items, offering visibility while protecting the contents.

Lids and Covers: Food containers often require a rigid lid. Food grade HIPS plastic sheet rolls is ideal for this, providing a strong, covering that maintains freshness product.

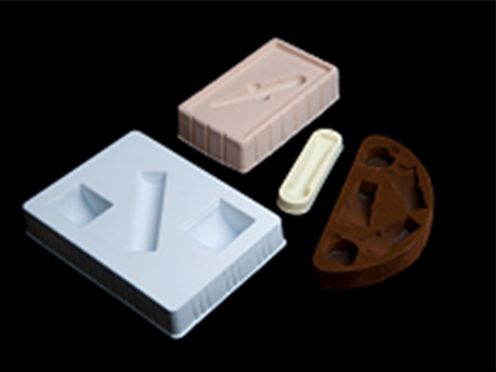

2. Thermoformed Packaging

Ready Meals and Takeout Packaging: HIPS plastic sheet rolls are easy to thermoform, allowing it to be molded into a variety of shapes to hold prepared meals, takeout, and deli foods.

Meat and Poultry Packaging: The material can be used for creating vacuum-sealed trays for meats, ensuring the food stays fresh for longer.

Deli Food Trays: For foods such as sliced meats, cheeses, and prepared salads, HIPS plastic sheet rolls offers a durable, sanitary packaging option that helps preserve food quality.

Bakery Goods: HIPS plastic sheet rolls are used in the production of clamshells or trays for bakery items like cakes, pastries, and muffins, where product visibility is important.

3. Food Transport and Shipping

Shipping Trays and Boxes: For transporting bulk food items, HIPS is used to create rigid, durable trays or boxes that can withstand handling during shipping while keeping the food safe from contamination.

4. Medical and Pharmaceutical Food Applications

Packaging for Nutritional Supplements: Food-grade HIPS is sometimes used to package vitamins, nutritional supplements, or other health-related food items where transparency and stability are required.

5. Custom Applications

Custom Molding for Specific Food Products: Due to its versatility in thermoforming, HIPS plastic can be custom-molded for specific food products that require unique shapes or sizes for packaging.

Benefits in Food Packaging

1. High Impact Resistance: Ensures the packaging is strong enough to withstand physical stress during transport and handling.

2. FDA Approval: Food grade HIPS plastic sheet rolls are manufactured to meet FDA or EU food safety standards, ensuring it is safe for food contact.

3. Good Aesthetics: The material’s transparency makes it visually appealing and perfect for showcasing the food inside.

4. Cost-Effective: HIPS is relatively inexpensive compared to other plastic materials, making it a popular choice for mass production.

Limitations:

5. Temperature Sensitivity: Food grade HIPS plastic sheet rolls are are not ideal for high-heat food processing applications, such as microwaveable meals that require the material to withstand high temperatures.

6. Brittleness: Food grade HIPS plastic sheet rolls are while it has good impact resistance, it can be prone to cracking under certain conditions, particularly if exposed to high temperatures.

The processing of food grade HIPS (high impact polystyrene) plastic sheet rolls mainly includes the following steps:

1. Raw material preparation: Purchase polystyrene resin and additives that meet food safety standards.

2. Extrusion molding: Heat the raw materials to a molten state and form uniform plastic sheets through an extruder.

3. Cooling and shaping: The cooling system allows the sheet to cool quickly to ensure uniform size and thickness.

4. Rolling into rolls: The cooled sheets are rolled into large rolls for easy storage and transportation.

5. Processing and trimming: If necessary, cutting, trimming, printing, thermoforming and other processing can be carried out.

6. Quality testing: Check thickness, size, physical properties and food safety tests to ensure compliance with standards.

7. Packaging and transportation: The final product is packaged to ensure safety, meet food grade requirements, and is ready for shipment.

This process ensures the quality and food safety of food grade HIPS plastic sheet rolls, which are suitable for a variety of applications such as food packaging and containers.

When selecting Food grade HIPS plastic sheet rolls, food packaging manufacturers should mainly consider the following factors:

1. Food safety certification: Ensure that the material complies with relevant food contact material certifications such as FDA or EU to ensure that no harmful substances are released.

2. Physical properties: The material must have good impact resistance, strength and toughness to protect food from damage during transportation and storage.

3. Processability: The material should be easy to thermoform, cut, weld, etc., and suitable for the production process of food packaging.

4. Environmental protection: Choose recyclable materials, meet environmental protection requirements, and reduce packaging waste.

5. Supplier reputation and service: Choose a reputable supplier to ensure the quality of the material and timely delivery.

In summary, food packaging manufacturers should comprehensively consider aspects such as food safety, packaging needs, processing convenience and environmental protection standards to choose the appropriate HIPS plastic sheet roll.

|

Product Name |

Food Grade HIPS Plastic Sheet Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.