Material Composition:

PETPrice Range:

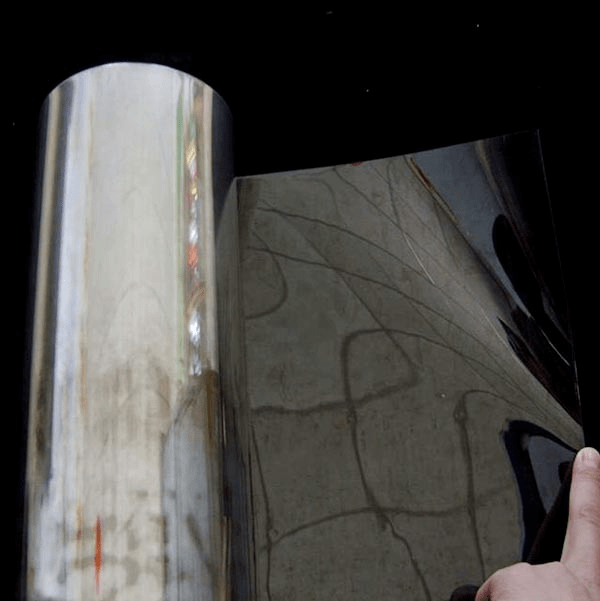

$1.25-$1.89/kgFood grade PET Plastic sheet rolls have excellent light transmittance, tensile strength, and high resistance to oxygen and water vapor.

Food grade PET plastic sheet rolls are designed for safe and effective food packaging. Manufactured from high-quality polyethylene terephthalate (PET), these sheets comply with food safety standards, ensuring they are non-toxic and free from harmful chemicals.

Key Features of Food Grade PET Plastic Sheet Rolls

1. Safety Assurance: FDA-approved for direct food contact, ensuring consumer safety.

2. High Clarity: Offers excellent transparency, showcasing product visibility while enhancing presentation.

3. Durability: Resistant to moisture, chemicals, and UV light, ensuring long-lasting performance in various environments.

4. Customizable Thickness: Available in various thicknesses to meet specific packaging needs.

5. Versatile Applications: Ideal for food trays, clamshell containers, and various packaging solutions in the food industry.

Benefits of Food Grade PET Plastic Sheet Rolls

1. Eco-Friendly Option: 100% recyclable, contributing to sustainable packaging solutions.

2. Cost-Effective: Provides excellent value without compromising quality, suitable for bulk production.

3. Easy to Process: Compatible with various printing and sealing technologies for seamless production.

Choose our Food Grade PET Plastic Sheet Rolls for reliable, safe, and high-quality food packaging solutions.

Food Grade PET Plastic Sheet Rolls are versatile and widely used in the food packaging industry. Here are some of their key applications:

1. Food Trays: Ideal for producing trays used in ready-to-eat meals, fresh produce, and bakery items, providing excellent presentation and protection.

2. Clamshell Containers: Perfect for clamshell packaging for fruits, vegetables, and baked goods, ensuring visibility while maintaining freshness.

3. Flexible Packaging: Used in the production of pouches and bags for snacks, candies, and frozen foods, offering moisture and barrier protection.

4. Deli and Takeout Packaging: Food Grade PET Plastic Sheet Rolls Commonly used for deli containers and takeout boxes, allowing for safe and convenient food storage.

5. Cosmetic and Nutritional Products: While primarily food-focused, these sheets are also suitable for packaging cosmetics and nutritional supplements, maintaining safety and quality.

6. Custom Applications: Can be tailored for specific applications such as vacuum packaging and thermoforming, meeting diverse industry needs.

These applications highlight the flexibility and effectiveness of Food Grade PET Plastic Sheet Rolls in ensuring safe, efficient, and visually appealing food packaging solutions.

| Specification | Properties | UNIT | METHOD | Virgin PET | Pre-consumer/Post Recycled PET | |||

|---|---|---|---|---|---|---|---|---|

| Data | (ASTM) | 100% PET | RPET 25% | RPET 30% | ||||

| Sheet Specification | Thickness Tolerance | %/mm | / | ±5% | ±5% | ±5% | ||

| Thickness Range | mm | / | 0.18 – 1.8 | 0.18 – 1.8 | 0.12 – 1.8 | |||

| Width Tolerance | mm | / | ±2mm | ±2mm | ±2mm | |||

| Width Range | mm | / | 200 – 1400 | 200 – 1400 | 200 – 1400 | |||

| Weight Tolerance | % | / | ±3% | ±3% | ±3% | |||

| Physical Property | Elongation at break | X direction | % | D882 | 19 | 17 | 17 | |

| Y direction | D882 | 19 | 19 | 19 | ||||

| Heat Shrinkage | Horizontal | % | D1204 | <2.0 (0.45mm) | <2.0 (0.45mm) | <2.0 (0.45mm) | ||

| Vertical | 110°C(5min) | <8.0 (0.45mm) | <8.0 (0.45mm) | <8.0 (0.45mm) | ||||

| Specific Gravity | g/cm3 | D792 | 1.35 | 1.35 | 1.35 | |||

| Tensile strength | X direction | Mpa | D882 | 56.8 | 54 | 54 | ||

| Y direction | 57.3 | 54 | 54 | |||||

| Surface Resistivity (25°C 50%RH) | ohms/sq (Ω) | D257 | <1013 | <1013 | <1013 | |||

| Glass Transition Temperature | °C | (DSC) | 73.6 | 73.6 | 73.6 | |||

| Melting point | °C | (DSC) | 249.4 | 247.4 | 247.4 | |||

| Printing Capability | Dynes | D2578 | 34-36 | 34-36 | 34-36 | |||

| Impact Strength (Dart) | g | D1709 | >2400 (0.45mm) | >2100 (0.45mm) | >2100 (0.45mm) | |||

| Water Absorption | % | D570 | 0.64 | 0.72 | 0.72 | |||

| Surface Hardness | D3363 | B | 4B | 4B | ||||

| Vacuum Forming / Static Friction | / | D1894 | <0.35 (0.45mm) | <0.35 (0.45mm) | <0.35 (0.45mm) | |||

| Folding Box/ Printing / Dynamic Friction | / | D1894 | <0.28 (0.45mm) | <0.28 (0.45mm) | <0.28 (0.45mm) | |||

| Light Transmittance | % | D1003 | >88 | >87 | >87 | |||

| Haze | % | D1003 | <5 | <5 | <5 | |||

Here are some precautions for using food-grade PET plastic sheet rolls:

1. Check Certification: Ensure that the PET sheets are certified as food-safe and meet relevant food contact regulations.

2. Storage Conditions: Store sheets in a cool, dry place away from direct sunlight to prevent degradation.

3. Cleaning: Clean surfaces before contact with food. Use mild detergents and avoid harsh chemicals that could compromise safety.

4. Temperature Limits: Be aware of the temperature range for safe use; avoid exposing PET sheets to extreme heat or cold.

5. Avoid Contamination: Prevent contact with non-food-safe materials during storage and handling to avoid contamination.

6. Proper Cutting Tools: Use appropriate tools to cut the sheets to prevent damage and ensure safety.

7. Monitor for Damage: Regularly inspect sheets for any signs of wear or damage, and replace as necessary to maintain food safety.

8. Disposal: Follow local guidelines for disposing of PET plastic sheet rolls to minimize environmental impact.

|

Product Name |

Food grade PET Plastic sheet rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.