EVOH is a crystalline polymer with a chain structure. It combines the good processability of ethylene polymer with the extremely high gas barrier properties of vinyl alcohol polymer. It is a new type of barrier material. Its gas barrier property is 100 times higher than that of PA (polyamide), 10,000 times higher than that of PE and PP, and dozens of times higher than that of the commonly used high barrier material PVDC (polyvinylidene chloride).

In addition, EVOH is excellent in transparency, gloss, mechanical strength, stretchability, abrasion resistance, cold resistance and surface strength. At the same time, it has the highest thermal stability of high-performance barrier resins, which allows the waste produced in processing to be recycled.

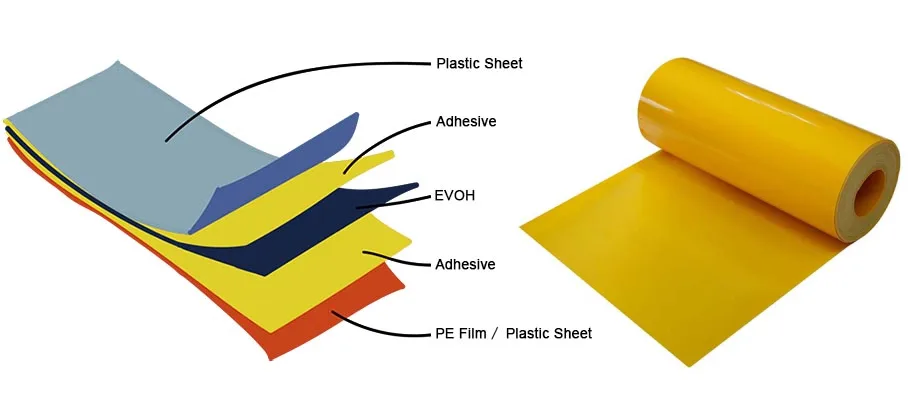

Features of EVOH composite plastic sheet:

1. High barrier: The performance of isolation by different plastic materials is very different. Five/seven layers of co-extruded film can achieve the actual effect of high barrier to oxygen, water, carbon dioxide, odor, etc.

2. Strong effect: acid and alkali resistance, wet and cold resistance, continuous high temperature steaming at 120 ℃, resistance to low temperature refrigeration, quality assurance, refrigeration, and odor preservation, and can be used for vacuum preservation, aseptic testing outer packaging, and inflatable packaging bags.

3. Low cost: Relatively environmentally friendly packaging, aluminum foil bags and other plastic packaging products, to achieve the same actual blocking effect, the five/seven-layer co-extruded film has great advantages in cost. Because the processing technology is simple, the cost of the manufactured film product can be reduced by 10%-20% compared with the dry test composite film and other composite films.

In terms of packaging materials, EVOH has excellent gas barrier properties, which can significantly prolong the storage time of food and improve the aroma retention of food. It can be used to package ketchup, sugar juice, dairy products, meat products, vegetables, juices and beverages. The use of plastic containers containing EVOH resin can completely replace glass and metal containers.

The addition of EVOH not only greatly improves the multi-layer film's high barrier to oxygen and aroma, composite release strength, anti-mirror resistance and refrigerated storage period, but also completes the effect of various materials, low cost, suitable secondary The process performance has replaced many packaging design sales markets with dry test compounding as the core, and there is no residual environmental pollution of adhesives.

The seven-layer co-extruded film is most suitable for the outer packaging of food crops, food, chemical raw materials, fertilizers, acetamiprid, mining tools, and pharmaceutical products with high oxygen barrier, waterproof and strength requirements. It has become a new type overseas. The development trend of packaging bags.