Material Composition:

HIPS PlasticPrice Range:

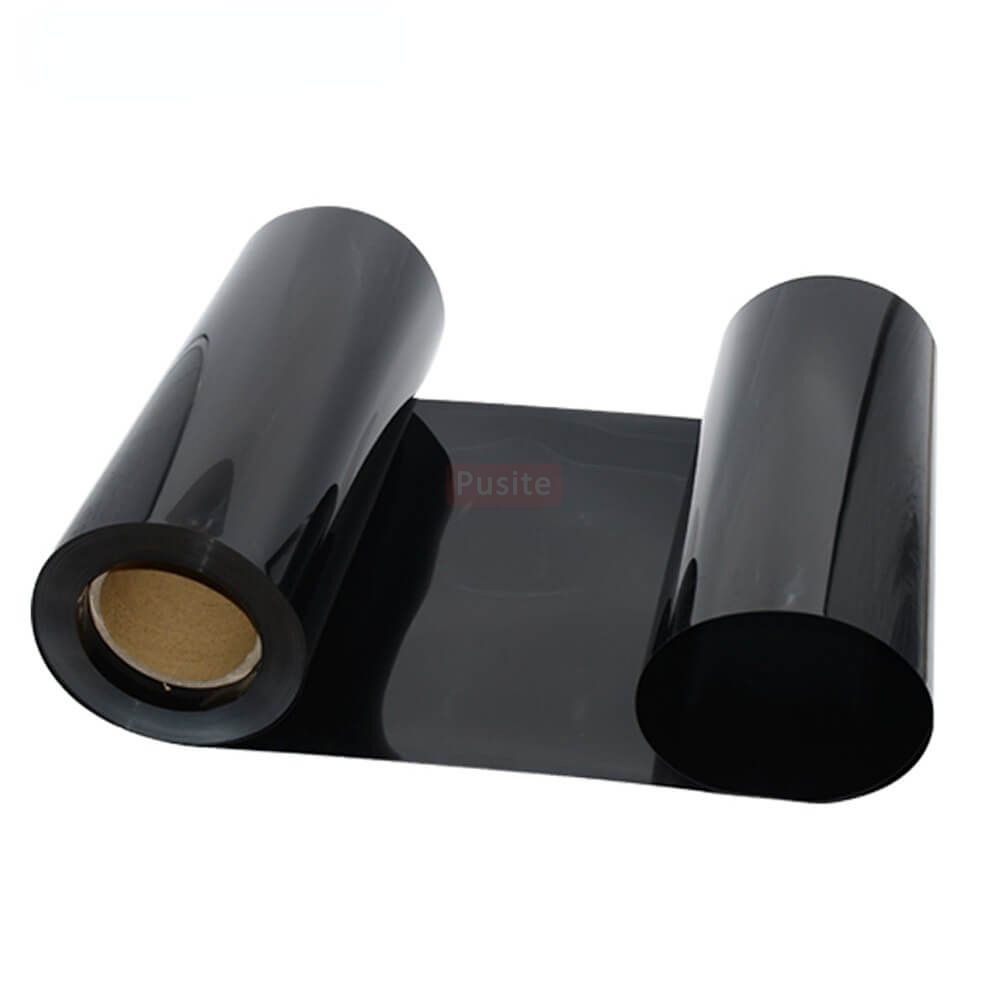

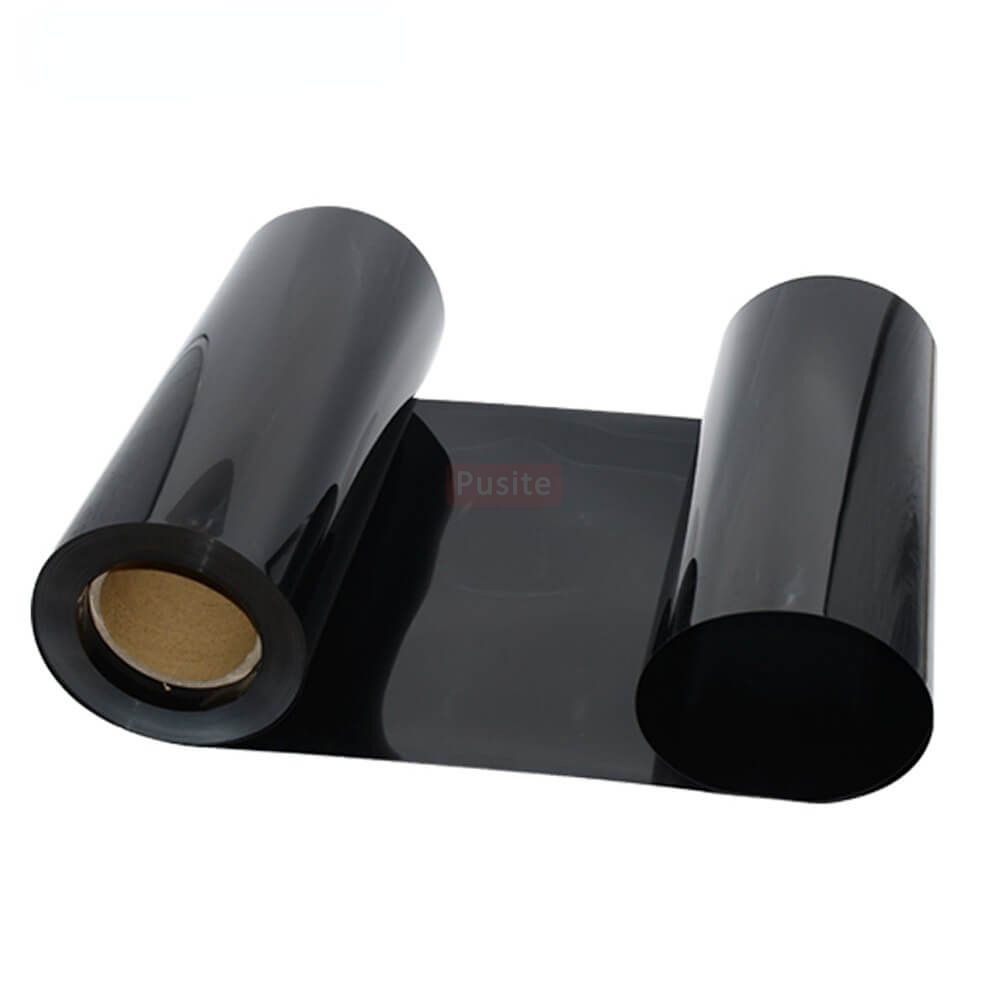

Price Range: 1.25-1.89$HIPS (High Impact Polystyrene) Plastic Rolls are a popular choice for food packaging due to their combination of impact resistance, ease of thermoforming, and cost-effectiveness. The material’s ability to be molded into various shapes, along with its excellent transparency and rigid structure, makes it ideal for creating attractive and functional food packaging solutions.

High Impact Polystyrene (HIPS) plastic rolls are a premium packaging solution designed to meet the diverse needs of the food packaging industry. Known for their superior durability and versatility, HIPS plastic rolls provide an ideal packaging material for a wide range of food products, from fresh produce to processed snacks and ready-to-eat meals.

HIPS plastic rolls are a thermoplastic material with a high impact resistance, which ensures that food products remain protected during transportation and storage. It is lightweight yet strong, offering the perfect combination of structural integrity and aesthetic appeal. HIPS plastic rolls are ideal for thermoforming, a popular method used to produce packaging like trays, clamshells, and blister packs.

1. Superior Impact Resistance

HIPS plastic rolls are highly resistant to impact and shock, making them an excellent choice for packaging fragile food items, such as fresh fruits, vegetables, snacks, and confectioneries. This resistance helps prevent damage during handling, reducing product loss and maintaining food quality.

2. Crystal Clear Transparency

The clarity of HIPS plastic rolls allows consumers to see the packaged food, enhancing the visual appeal of products. Its glossy finish highlights the freshness of the contents, making it a popular choice for packaging fresh produce, bakery items, and premium products.

3. Excellent Thermoforming Properties

HIPS plastic rolls are easily thermoformed into various shapes and sizes, making it adaptable for a wide variety of food packaging applications. Whether it’s for pre-formed trays, vacuum-formed packaging, or clamshell containers, HIPS plastic rolls offer high flexibility for custom designs that fit the specific needs of food manufacturers.

4. Food Safety Compliance

HIPS plastic rolls are FDA-approved and meet food contact material regulations, ensuring that they are safe for use in direct contact with food products. This makes HIPS a trusted material in the food industry, as it helps preserve product freshness without compromising food safety.

5. Eco-Friendly and Recyclable

As sustainability becomes an increasing priority in the packaging industry, HIPS offers an eco-friendly solution. It is fully recyclable, allowing food producers and consumers to contribute to reducing plastic waste and supporting a circular economy.

6. Cost-Effective Solution

HIPS plastic rolls are relatively cost-effective compared to alternative materials like PET or PVC. Their affordability, combined with their durability and versatility, makes them a preferred choice for large-scale food packaging applications.

1. Fresh Produce Packaging: HIPS plastic rolls are widely used for packaging fruits, vegetables, and other fresh produce, offering protection and visibility while maintaining freshness.

2. Snack Food and Confectionery: With its excellent impact resistance and clear, glossy finish, HIPS is ideal for packaging snack foods, chips, candies, and other confectionery products, enhancing both product appeal and safety.

3. Ready-to-Eat and Frozen Meals: HIPS is commonly used in packaging ready-to-eat meals and frozen food items due to its ability to preserve product integrity during transportation and storage.

4. Bakery Items: HIPS provides a secure and visually appealing packaging solution for baked goods, such as pastries, cakes, and cookies, keeping them fresh while showcasing their quality.

| Parameter | Description |

|---|---|

| Material Type | High Impact Polystyrene (HIPS) |

| Thickness | 0.3 mm to 2.0 mm (customizable) |

| Width | 300 mm to 850 mm (customizable) |

| Length | Up to 3000 meters (depending on order) |

| Transparency | Clear, Glossy Finish |

| Impact Resistance | High impact resistance, ideal for fragile items |

| Food Safety Compliance | FDA-approved for direct food contact |

| Color | Clear (custom colors available upon request) |

| Temperature Range | -40°C to 90°C (for food packaging purposes) |

| Recyclability | Fully recyclable |

| Applications | Fresh produce, snacks, frozen meals, bakery items, etc. |

| Customization Options | Custom sizes, thickness, and perforation options available |

HIPS plastic rolls are an excellent choice for manufacturers looking to balance durability, safety, aesthetics, and cost-effectiveness. Whether you're packaging fresh produce, snacks, or frozen meals, HIPS plastic provides the perfect solution for delivering high-quality, visually appealing, and safe food products to consumers.

With the ability to be easily formed into various shapes, along with its compliance with food safety standards, HIPS is poised to remain a leading material in the food packaging industry.

|

Product Name |

HIPS plastic rolls for food packaging |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.