When it comes to PET sheet, most people will be relatively unfamiliar, but they don't know that it has a wide range of uses. PET sheet is a kind of thermoplastic environmental protection plastic product, which is widely used for packaging in cosmetics, food electronics, toys, printing and other industries. Many downstream customers of PET sheet manufacturers will respond to a problem, that is, the problem of product yellowing. Are there any additives that can solve this problem.

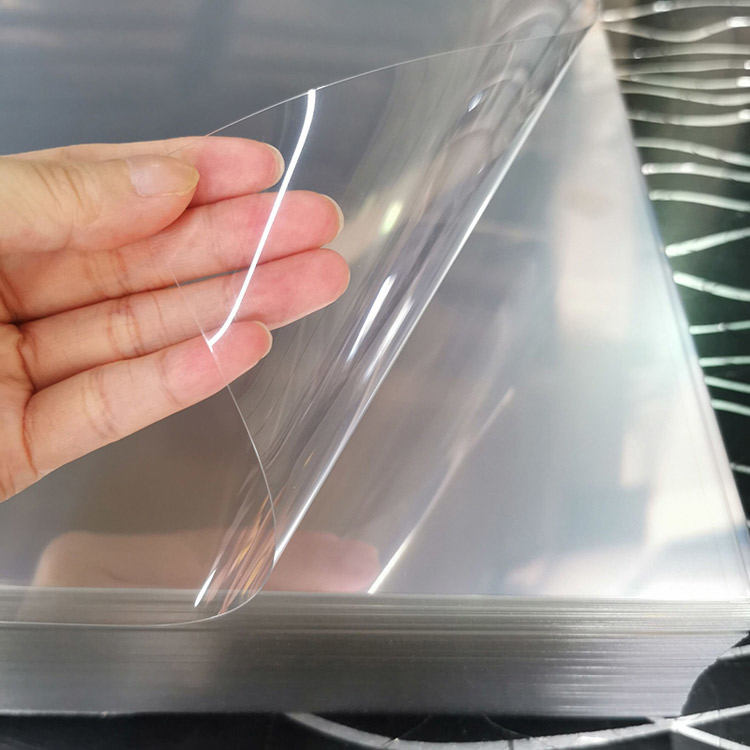

PET sheet is also called polyester rigid film. Its edge material and waste can be recycled. PET products have the characteristics of no crystal points, high transparency, good gloss, and strong impact resistance. It is a newly developed material. , It has excellent toughness, high strength, good transparency, coupled with strong recycling performance, it is currently sought after by many manufacturers.

However, many PET sheet manufacturers will encounter problems such as product yellowing and lack of transparency during the production process, which directly affects sales. To solve this problem, we suggest adding a yellowing and whitening agent in the production process. In the PET sheet, the amount of the yellowing and whitening agent added is very small, only the amount of 0.02%-0.05% is added, the whiteness value and brightness value of the product Will improve a lot.

In addition, the anti-yellow whitening agent has good weather resistance. We all know that ultraviolet rays are the culprit that causes the article to turn yellow and fade. The anti-yellow whitening agent can absorb ultraviolet light and effectively increase the service life of the product. Even if it is used for a long time, the product will not turn yellow. fade.

Sheets added with yellowing and whitening agents not only improve the appearance, but also greatly reduce production costs for PET sheet manufacturers. After all, the recycling performance of PET sheets is relatively strong. In the case of lack of raw materials, many manufacturers will use them. Recycling the old materials for production, and adding the yellowing and whitening agent to the recycled materials, the appearance of the products made is the same as that of the new materials.