Store High impact polystyrene (HIPS) plastic rolls in a cool, dry environment. Avoid exposure to direct sunlight or heat, as prolonged exposure can cause the material to degrade.

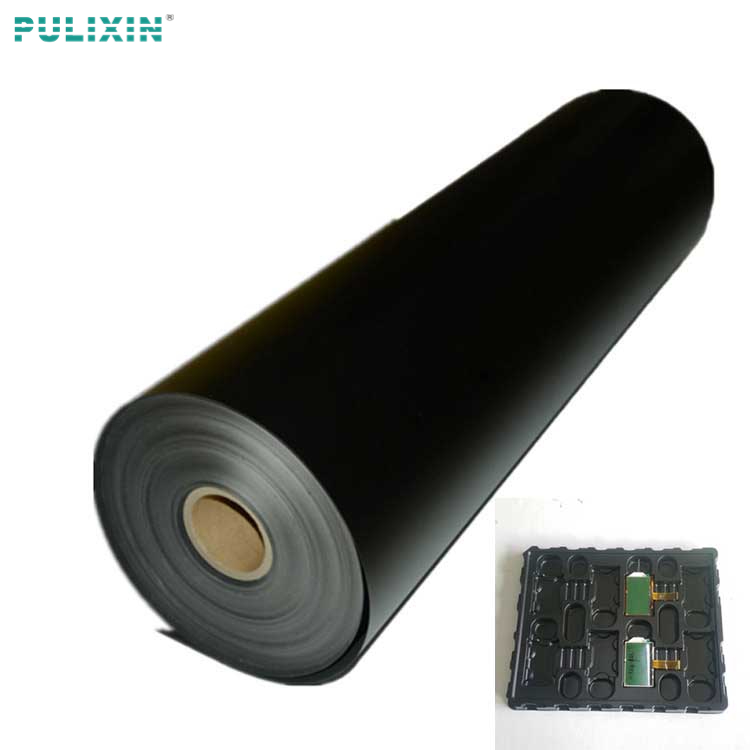

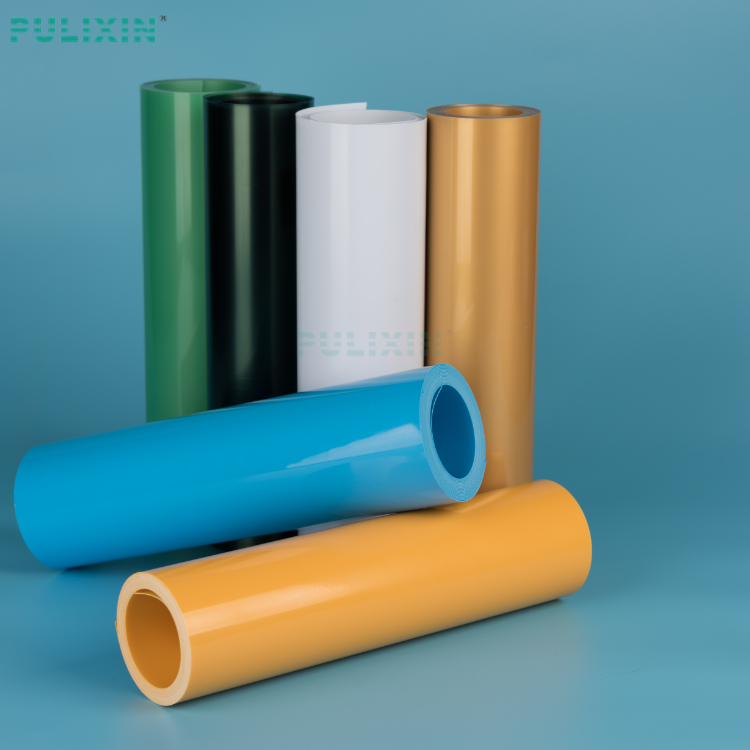

HIPS plastic roll has the advantages of impact resistance, rigidity, cost effectiveness, easy manufacturing, electrical insulation, chemical resistance, etc., is a suitable choice for electronic pallet.

HIPS plastic rolls has good impact resistance, making it suitable for packaging applications where protection of the enclosed product is important.

When processing HIPS plastic rolls, you need to pay attention to temperature control, safe operation, selecting appropriate equipment and tools, maintaining good ventilation and waste disposal, avoiding over-processing, and rationally designing products.

There are a lot of materials that we don’t know are widely used in daily life, such as PP materials, household utensils and containers such as plastic bowls, cups, boxes, etc. are all made of PP materials, so in the end PP What material is it? h

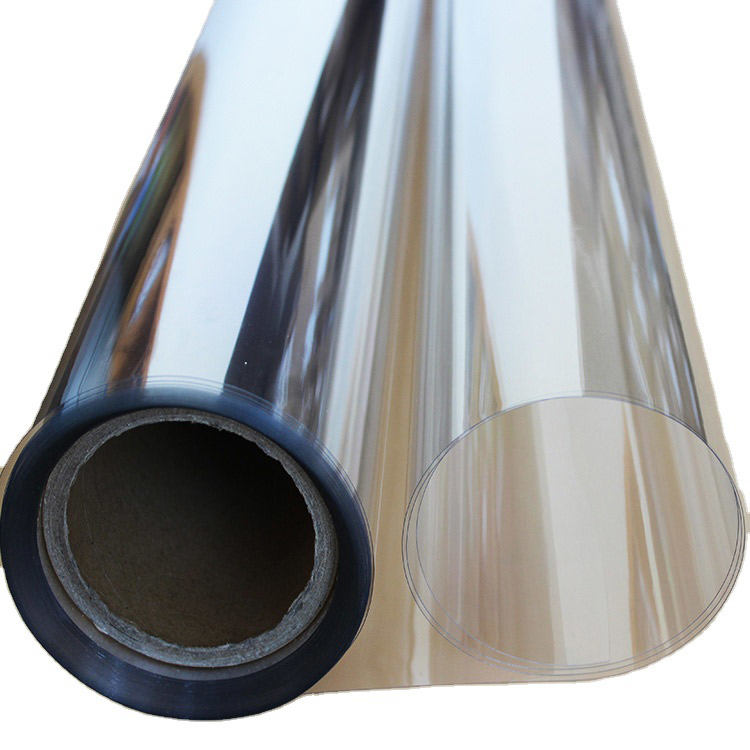

PET sheet is a new type of plastic product recently developed in recent years, so what is the difference between it and our traditional plastic? First of all, the production process of this material is more complicated. It is produced through a series of

PP sheets can be made into various products through secondary processing such as thermoforming, and are mainly used for packaging of food, medicine, medical equipment, etc.

Compared with PET, the biggest feature of PETG is that PETG conforms to the concept of environmental protection and food FDA certification.

Blister is the process of heating, vacuum forming, cooling and other processes of PVC, PS, PET and other resin sheets in a blister molding machine to make it according to the shape of the mold, and then stamping it into a single product with a knife die o

PS blister is a blister product made of PS sheet through a vacuum blister forming process. The production principle of the product is to heat the flat blister hard sheet material to soften it, adsorb it on the surface of the blister packaging mold with va