Blister is a production process in which PP, PET, PS and other plastic sheets are heated at high temperature and vacuum formed on the mold. Blister packaging is a general term for plastic products manufactured by the blister process, and the molded produc

Anti -ultraviolet PET plastic sheet can block ultraviolet light, avoid damage, and extend the service life. Widely used in the packaging of cosmetics, food, electronics, toys, toys...

The polyester sheet series includes PETG, APET, CPET, etc., which are new sheet products developed and developed rapidly in recent years.

PS blister is a blister product made of PS sheet through a vacuum blister forming process. The production principle of the product is to heat the flat blister hard sheet material to soften it, adsorb it on the surface of the blister packaging mold with va

PET blister is a blister product made of PET sheets through a vacuum forming process.

Plastic products such as cups, boxes, and trays can be seen everywhere in life. We often see numbers 1 to 7 on plastic products. What do these seven numbers represent?

In terms of packaging materials, EVOH has excellent gas barrier properties, which can significantly prolong the storage time of food and improve the aroma retention of food.

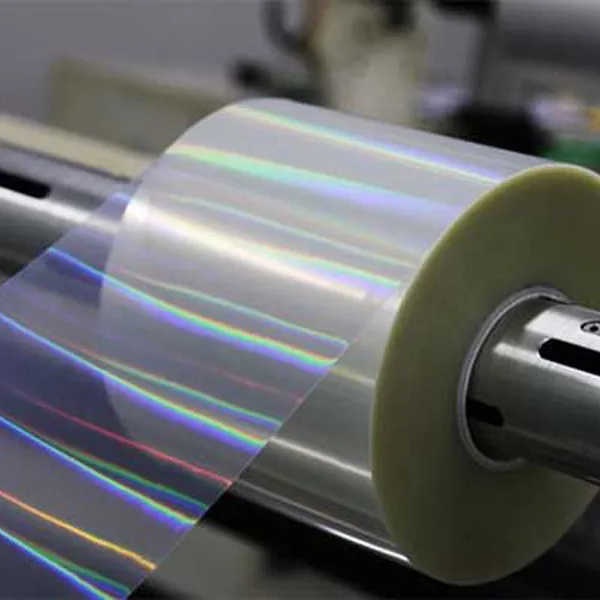

PET sheet is gradually favored by consumers and producers due to its excellent toughness, high strength, high transparency, recyclability and excellent environmental protection performance that does not produce harmful gases during combustion.

Pusite is an excellent PP plastic sheet manufacturer in China and a leader in the industry. We use 100% pure plastic masterbatch raw materials, and all products are of high quality and guaranteed.

Plastic can be said to be closely related to our lives. The plastic family is very rich, there are six common plastics, let's learn about them.