Material Composition:

PET PlasticPrice Range:

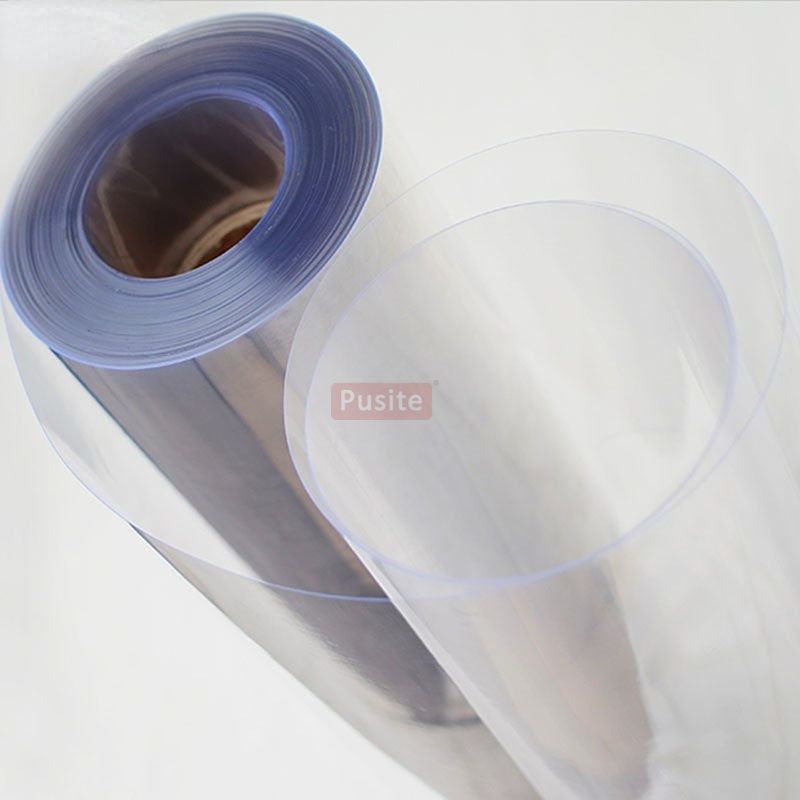

$1.28-$1.92/kgPusite hight clarity and transparency PET Plastic Sheet Rolls for Clamshell Trays.

PET (Polyethylene Terephthalate) plastic sheet rolls are commonly used to manufacture clamshell trays due to their excellent clarity, durability, and formability. Here’s a detailed overview of PET plastic sheet rolls for clamshell trays:

Characteristics of PET Plastic Sheets

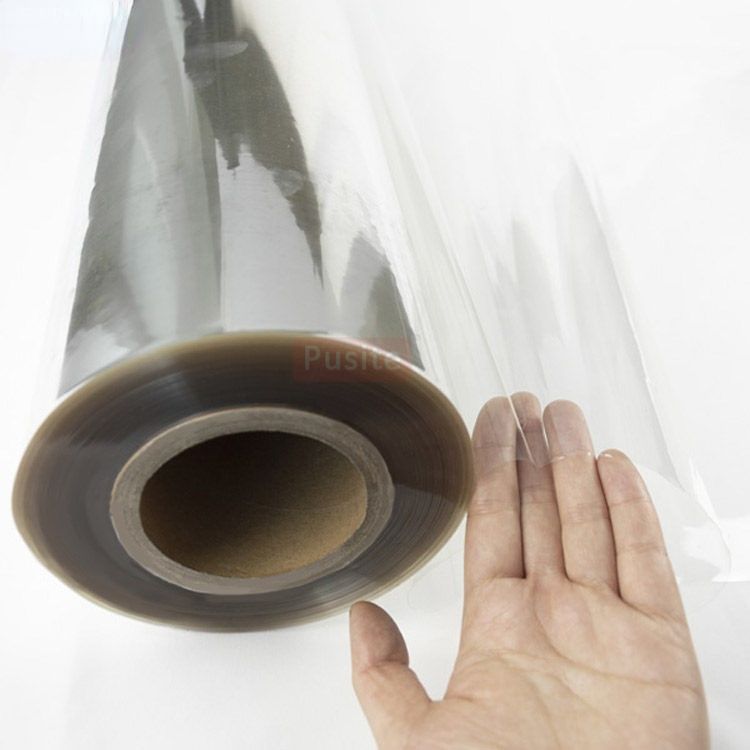

1. Clarity and Transparency: PET plastic sheet rolls offer high optical clarity, making them ideal for packaging applications where visibility of the product is important.

2. Strength and Durability: PET plastic sheet rolls has a high tensile strength and is resistant to impact, ensuring that clamshell trays can protect the contents during handling and transportation.

3. Chemical Resistance: PET plastic sheet rolls is resistant to many chemicals, including oils and greases, which helps in maintaining the integrity of the packaged product.

4. Thermoformable: PET plastic sheet rolls can be easily heated and molded into various shapes, making them suitable for creating clamshell designs that securely encase items.

5. Recyclability: plastic sheet roll is widely recyclable, making it an environmentally friendly option for packaging solutions.

Specifications of PET Plastic Sheet Rolls

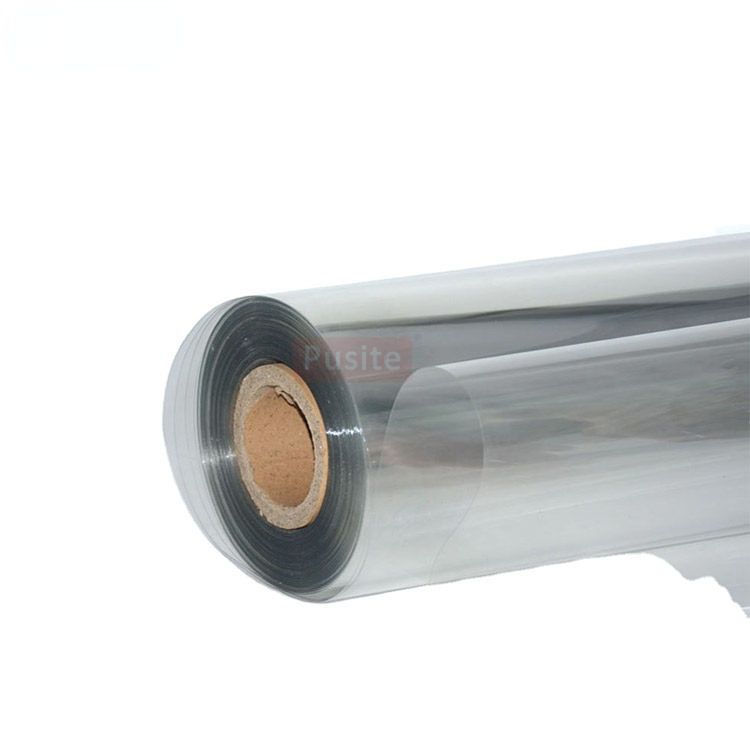

Thickness: PET sheet rolls typically range from0.18~2.0mm.

Width: Standard widths can vary, with common sizes being between 300~1400mm.

Considerations of Clamshell Trays

Temperature Resistance: While PET can withstand a range of temperatures, it may not be suitable for high-heat applications (e.g., microwaving).

Processing Conditions: It’s important to control processing conditions (temperature, pressure) during thermoforming to achieve optimal results.

1. Food Packaging: PET plastic sheet rolls are widely used in food packaging, including refrigerated and frozen foods, prepared foods, snacks, and beverage containers.

2. Pharmaceuticals and Medical Devices: In the medical industry, PET plastic sheet rolls are used to package pharmaceuticals, medical devices, and disposables to ensure their hygiene and safety.

3. Electronics Packaging: Used to package electronic products such as mobile phones, accessories, and other small devices to provide protection and facilitate display.

4. Stationery and Office Supplies: PET plastic sheet rolls can be used to make folders, notebook covers, and other office supplies to provide durability and visual appeal.

5. Toys and Gift Packaging: In the toy industry, PET plastic sheet rolls can be used to make transparent packaging boxes and clamshell boxes to display products and protect their safety during transportation.

6. Display and Advertising Materials: PET plastic sheet rolls can be used to make signs, exhibitions, and display stands, because of its good transparency and durability, it can attract customers' attention.

7. Construction and decoration: In the construction industry, PET plastic sheet rolls can be used to make windows, partitions and decorative elements because of its lightness and good light transmittance.

8. Cosmetic packaging: Used in the packaging of cosmetics and skin care products to provide good product display and protection.

The wide application of PET plastic sheet rolls makes it a common material in many industries due to its excellent performance and environmental protection characteristics.

The benefits of using PET plastic sheet rolls for clamshell trays include:

1. High Clarity and Visibility: PET plastic sheet rolls offer excellent transparency, allowing consumers to easily see the contents, which is especially important for retail packaging.

2. Durability and Strength: PET is known for its toughness and resistance to impact, ensuring that clamshell trays protect the products inside during handling and shipping.

3. Lightweight: PET trays are lightweight, reducing shipping costs and making them easier to handle for both manufacturers and consumers.

4. Thermoformability: PET sheets can be easily heated and molded into various shapes, making them suitable for creating custom clamshell designs that securely hold items.

5. Chemical Resistance: PET is resistant to many chemicals, including oils and greases, ensuring that the contents remain safe and uncontaminated.

6. Recyclability: PET is widely recyclable, making it an environmentally friendly option that appeals to eco-conscious consumers and companies.

7. Cost-Effectiveness: PET plastic sheet rolls are relatively inexpensive compared to other materials, providing an economical solution for manufacturers.

8. Customizability: PET plastic sheet rolls can be customized in terms of thickness, size, and color, allowing manufacturers to tailor the product to their specific needs.

9. Good Barrier Properties: PET offers good moisture and oxygen barrier properties, which can help prolong the shelf life of food products.

10. Safety Features: PET is generally considered safe for food contact, complying with regulatory standards, making it suitable for food packaging applications.

These benefits make PET plastic sheet rolls a popular choice for producing clamshell trays across various industries.

| Product name | Pet plastic sheet rolls, Polyethylene Terephthalate plastic sheet rolls, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

|

Product Name |

PET Plastic Sheet Rolls for Clamshell Trays |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.