Material Composition:

PET PlasticPrice Range:

$1.25-$1.89/kgPusite (Shanghai) is one great PET plastic sheet rolls for disposable drink cup supplier, PET plastic sheet rolls manufacturer in the plastic sheet industry. Due to the exclusive advanced technology, Pusite (Shanghai) has gained 39 new product patents, can be able to supply high quality conductive plastic sheet with very affordable competitive market price. With more than 10 years foreign trade export experience, Pusite (Shanghai) has gained a great reputation from more than 60 countries' clients. With reasonable price, high quality guarantee, win-win cooperation principle, Pusite (Shanghai) will continue to spread business partners with global customers.

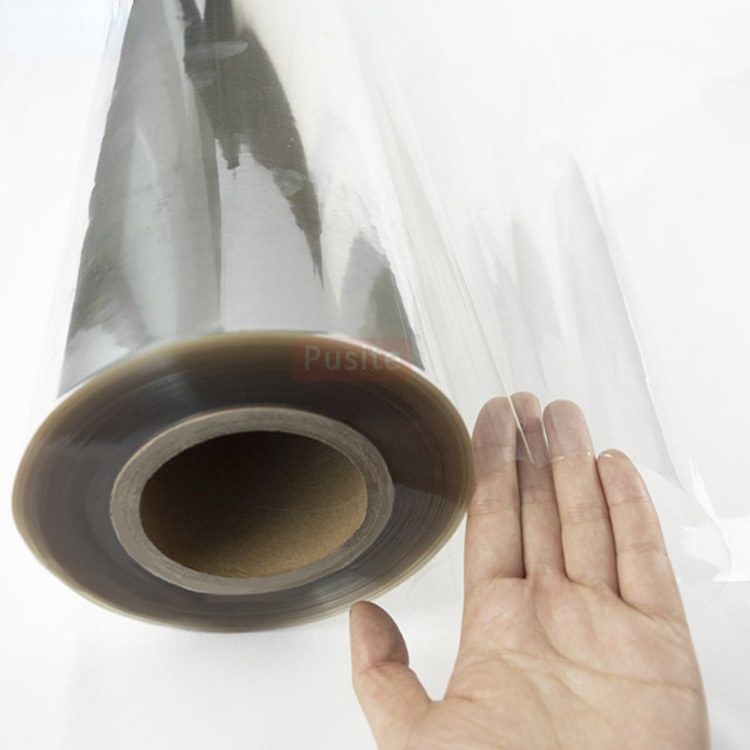

PET plastic sheet rolls for disposable drink cups are lightweight, transparent, and have excellent barrier properties, making them ideal for food packaging. They're commonly used in the production of clear drink cups due to their durability and safety for food contact.

PET (Polyethylene Terephthalate) plastic sheet rolls are widely used in the production of disposable drink cups due to their favorable properties. These rolls are made from a thermoplastic polymer that is both lightweight and robust, ensuring that the cups can withstand temperature variations and maintain structural integrity.

1. Clarity and Aesthetic Appeal: PET plastic sheet rolls offer excellent transparency, enhancing the visual presentation of beverages.

2. Barrier Properties: They provide effective barriers against moisture, gases, and odors, helping to preserve the freshness and flavor of the drinks.

3. Safety: PET plastic sheet rolls are FDA-approved for food contact, making it safe for use in food and beverage applications.

4. Recyclability: PET plastic sheet rolls are one of the most widely recycled plastics, supporting sustainability efforts in packaging.

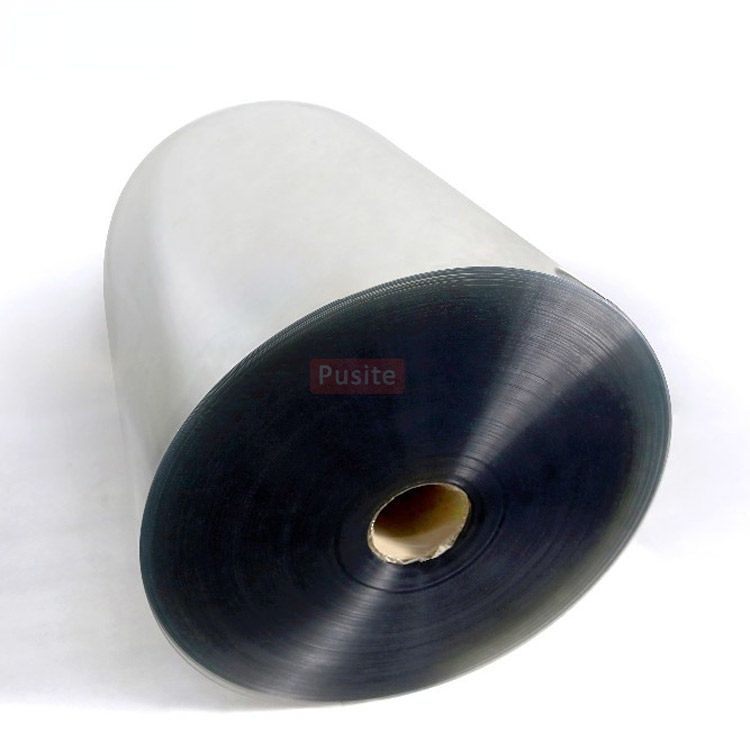

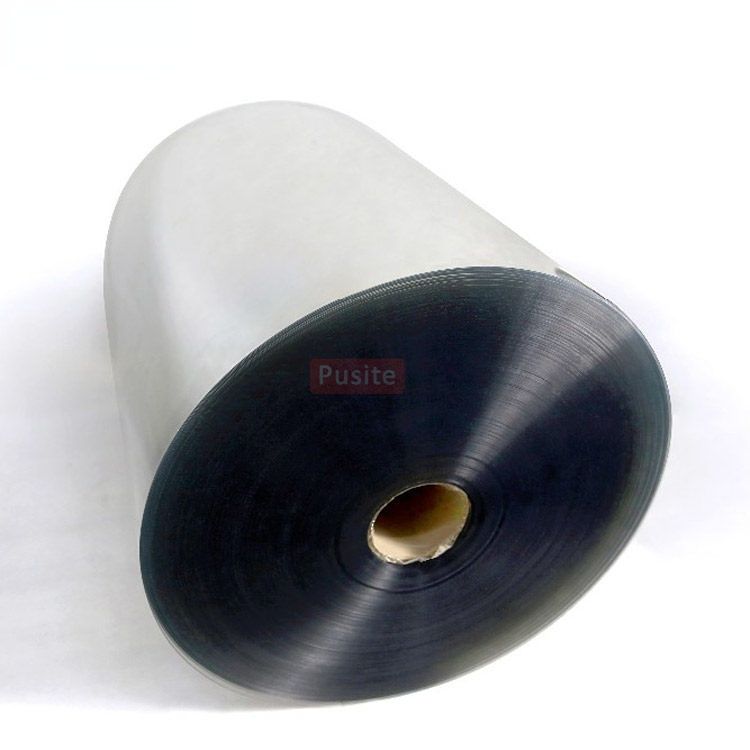

5. Customization: The PET plastic sheet rolls can be easily customized in terms of thickness, size, and color, catering to various design requirements.

1. Disposable Cups: Commonly used for serving cold drinks, such as sodas, juices, and iced coffees.

2. Food Service: Ideal for fast food and catering services due to their convenience and disposability.

Disposable plastic drink cups are designed for single-use and are typically made from materials like polyethylene (PET). Their main functions include:

1. Convenience: They can be discarded after use, eliminating the need for washing and saving time.

2. Hygiene: Each cup is a new product, reducing the risk of cross-contamination.

3. Lightweight and Portable: They are suitable for various occasions, such as parties, picnics, and fast-food restaurants.

4. Variety: They can be produced in different shapes and sizes to meet diverse beverage needs.

5. Cost-Effectiveness: They are relatively low-cost to produce, making them suitable for large-scale use.

In summary, disposable plastic drink cups play an important role in providing convenience and hygiene.

Choosing PET plastic sheet rolls for making disposable drink cups offers several advantages:

1. Lightweight and Durable: PET plastic sheet rolls are lightweight yet strong, making it suitable for transport and use without compromising structural integrity.

2. Excellent Clarity: The transparency of PET plastic sheet rolls enhances the visual appeal of beverages, allowing consumers to see the drink inside.

3. Good Barrier Properties: PET plastic sheet rolls provides effective protection against moisture, oxygen, and flavors, helping to maintain the freshness and quality of beverages.

4. FDA Approval: PET plastic sheet rolls are safe for food contact and complies with health regulations, ensuring consumer safety.

5. Recyclability: PET plastic sheet rolls are one of the most recyclable plastics, contributing to environmental sustainability and reducing landfill waste.

6. Versatility: PET plastic sheet rolls can be customized in thickness, size, and color, allowing manufacturers to create unique designs for branding and marketing.

7. Cost-Effective: PET plastic sheet rolls are generally economical to produce, making it a cost-effective choice for large-scale manufacturing.

These benefits make PET plastic sheet rolls a popular choice for disposable drink cups in the food and beverage industry.

PET plastic sheet rolls are a continuous roll of polyethylene terephthalate (PET) plastic film, widely used for various applications. It is known for its excellent clarity, strength, and chemical resistance. Key features include:

1. Transparency: PET plastic sheet rolls are highly transparent, making them ideal for packaging and display purposes.

2. Durability: They offer good impact resistance and are less prone to breakage compared to other materials.

3. Barrier Properties: PET plastic sheet rolls provides effective barriers against moisture and gases, helping to preserve the freshness of packaged products.

4. Versatility: They can be easily customized in terms of thickness, size, and finish, suitable for a range of applications, from food packaging to industrial uses.

5. Recyclability: PET plastic sheet rolls are one of the most widely recycled plastics, supporting environmental sustainability efforts.

PET plastic sheet rolls

Thickness: 0.18-2.0mm

Width: 300-1400mm

Color: Transparent or Customized

Special performance customization: Anti-fog, Printing, Coating, High impact, Waterproof, Oil-proof, Anti-UV, etc.

Delivery time: 7~15 days since receipt of PO and down payment.

Payment Accepted: D/A, D/P, T/T, L/C, Westunion etc.

Samples: Free samples supply

Overall, PET plastic sheet rolls are a popular choice in industries like packaging, food service, and manufacturing due to their performance and versatility.

To produce PET plastic sheet rolls for disposable drink cups, the following steps are typically involved:

1. Raw Material Preparation

PET Resin Selection: Begin by selecting high-quality PET (Polyethylene Terephthalate) resin. This resin is typically in pellet or granule form, and for drink cups, food-grade PET (FDA approved) is necessary.

Drying Process: PET resin absorbs moisture, which can negatively affect the material's properties. The resin is dried in a dehumidifying dryer to reduce the moisture content, typically below 0.005%.

2. Extrusion Process

Extruder Feeding: The dried PET resin is fed into an extruder. Inside the extruder, the resin is melted by high temperature and mechanical shear.

Screw Design: The extruder screw design ensures consistent melting, mixing, and homogenizing of the resin. The temperature is carefully controlled, usually between 250°C and 290°C, to maintain material integrity.

Additives: Additives like colorants, UV stabilizers, or anti-block agents may be mixed into the resin if required for specific properties like transparency or UV resistance.

3. Sheet Formation

Sheet Die: The molten PET is forced through a sheet die, which forms a flat, thin, and continuous sheet. The width and thickness of the sheet are controlled at this stage. For drink cup applications, common thicknesses range from 0.2mm to 0.8mm.

Calendering: The extruded sheet passes through calender rolls, which cool and further control the thickness. The rolls are usually water-cooled to ensure the sheet solidifies evenly without warping.

Surface Finishing: The calendering process also imparts surface finishes like gloss or matte, depending on the requirements.

4. Cooling and Trimming

Cooling: After calendering, the PET plastic sheets are cooled down on a cooling conveyor or in water baths to stabilize its dimensions and prevent shrinkage.

Trimming: The edges of the sheet are trimmed to the desired width to ensure consistency. The trimmed material is often recycled back into the production process.

5. Winding

Rewinding into Rolls: Once cooled and trimmed, the PET plastic sheets are wound into large rolls for easy handling and transportation. The winding tension must be carefully controlled to avoid wrinkles or creases in the sheet.

6. Quality Control

Inspection: The PET plastic sheet rolls are inspected for defects like thickness uniformity, clarity, and surface finish. They also undergo mechanical tests to ensure they meet the required properties for thermoforming into disposable drink cups.

7. Thermoforming (Optional)

In some facilities, the PET plastic sheet rolls may directly proceed to thermoforming, where the rolls are heated and molded into the final shape of drink cups using molds.

The resulting PET plastic sheet rolls can then be sent to manufacturers that will use thermoforming machines to create disposable drink cups for various applications.

|

Product Name |

PET plastic sheet rolls for disposable drink cup |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.