Material Composition:

PET PlasticPrice Range:

$1.28-$1.92/kgPET (Polyethylene Terephthalate) plastic sheet rolls are commonly used in medical blister packaging due to their durability, clarity, and ability to create a strong, protective barrier for sensitive medical products.

PET (Polyethylene Terephthalate) plastic sheet rolls are commonly used in medical blister packaging due to their durability, clarity, and ability to create a strong, protective barrier for sensitive medical products.

1. High Clarity: PET Plastic Sheet Rolls offers excellent transparency, allowing for clear visibility of the medical product inside the blister pack. This is crucial for quality control and product identification.

2. Barrier Properties: PET provides a strong barrier against moisture, gases, and contaminants, protecting the integrity and sterility of the medical products.

3. Durability: PET Plastic Sheet Roll is resistant to impact and has good mechanical strength, ensuring that the blister packaging can withstand handling and transportation without damage.

4. Lightweight: Despite its strength, PET Plastic Sheet Roll is lightweight, which helps in reducing shipping costs and the overall weight of medical packaging.

5. Chemical Resistance: PET Plastic Sheet Rolls is resistant to many chemicals, which is important in the medical field where the packaging may come into contact with various substances.

1. Pharmaceutical Packaging: PET plaastic sheet rolls are used for packaging tablets, capsules, and other small medical devices that require protection from environmental factors.

2. Sterile Packaging: PET blister packs are often used for sterile medical instruments, ensuring that they remain uncontaminated until use.

3. Single-Use Medical Devices: Items like syringes, needles, and small surgical instruments are commonly packaged in PET blister packs.

PET (Polyethylene Terephthalate) plastic sheet rolls offer several key advantages in medical blister packaging, making them a preferred choice in the industry. Here are the primary benefits:

1.High Clarity and Transparency

(1) Visibility: PET plastic sheet rolls provides excellent clarity, allowing healthcare professionals and consumers to easily see and identify the product inside the packaging without opening it.

(2) Quality Control: The transparency of PET plastic sheet rolls makes it easier to inspect products for defects or contamination, ensuring that only high-quality items reach the end-user.

2. Strong Barrier Properties

(1) Moisture Resistance: PET plastic sheet rolls creates an effective barrier against moisture, helping to maintain the integrity and efficacy of moisture-sensitive medical products like tablets and capsules.

(2) Gas Barrier: PET’s ability to block out gases, such as oxygen, ensures that the contents remain uncontaminated, extending the shelf life of the product.

(3) Contaminant Protection: PET plastic sheet rolls provides a strong barrier against dust, bacteria, and other contaminants, keeping sterile medical devices and pharmaceuticals safe.

3. Durability and Impact Resistance

(1) Protection: PET plastic sheet rolls is highly durable and resistant to impact, protecting the packaged products from damage during transportation, handling, and storage.

(2) Integrity: The strength of PET plastic sheet rolls ensures that the blister pack maintains its shape and does not crack or deform, even under stress.

4. Lightweight and Cost-Effective

(1) Material Efficiency: PET plastic sheet roll is a lightweight material, which reduces shipping costs and the overall weight of the packaging.

(2) Cost Savings: PET plastic sheet roll is cost-effective compared to other materials with similar properties, making it an economical choice for large-scale medical packaging needs.

5. Chemical Resistance

(1) Compatibility: PET plastic sheet roll is resistant to a wide range of chemicals, making it suitable for packaging products that may be exposed to various substances during storage or use.

(2) Sterilization: PET blister packs can withstand common sterilization methods, such as gamma radiation or ethylene oxide, without degrading or compromising the package's integrity.

6. Recyclability and Environmental Friendliness

(1) Recyclable: PET plastic sheet roll is fully recyclable, which aligns with the increasing demand for sustainable packaging solutions in the medical industry.

(2) Reduced Environmental Impact: The ability to recycle PET plastic sheet rolls helps in reducing waste and the environmental footprint associated with medical packaging.

7. Ease of Thermoforming

(1) Customizable: PET plastic sheet rolls can be easily thermoformed into complex shapes, allowing for the creation of customized blister packs that fit specific medical devices or pharmaceuticals.

(2) Precision: The thermoforming process with PET plastic sheet rolls ensures precise and consistent packaging, which is crucial for the safety and efficacy of medical products.

8.Compliance with Regulatory Standards

(1) Safety Assurance: PET plastic sheet rolls is widely recognized and accepted by regulatory bodies like the FDA for use in medical packaging, providing assurance that the material is safe and suitable for medical applications.

These advantages make PET plastic sheet rolls a versatile and reliable choice for medical blister packaging, ensuring that medical products are well-protected, visible, and compliant with industry standards.

When using PET (Polyethylene Terephthalate) plastic sheet rolls in medical blister packaging, several important considerations must be taken into account to ensure the packaging's effectiveness, safety, and compliance with regulatory standards. Here are key factors to consider:

1. Sterilization Compatibility

(1) Sterilization Methods: PET plastic sheet rolls must be compatible with the sterilization processes commonly used in the medical industry, such as gamma radiation, ethylene oxide (EtO), or steam autoclaving. PET’s ability to maintain its integrity and barrier properties during and after sterilization is crucial.

(2) Thermal Stability: Consideration must be given to the thermal stability of PET during sterilization, especially for processes that involve heat, to avoid warping or compromising the packaging.

2. Regulatory Compliance

(1) FDA and International Standards: PET used in medical packaging must comply with regulations set by the FDA, ISO, and other relevant bodies. These standards govern aspects such as material safety, biocompatibility, and performance.

(2) Material Traceability: Ensure that the PET material can be traced back to its source and meets the necessary certifications for medical use, which is important for quality control and regulatory audits.

3. Product Compatibility

(1) Chemical Interaction: Assess the potential for chemical interaction between the PET packaging and the medical products. While PET is chemically resistant, it’s important to confirm that there will be no adverse reactions with the packaged products, especially with pharmaceuticals.

(2) Product Sensitivity: Consider the sensitivity of the product to factors like moisture, oxygen, or light. PET’s barrier properties should be matched to the specific needs of the medical product to ensure long-term protection.

4. Environmental Conditions

(1) Storage and Transportation: Evaluate how the PET plastic sheet rolls packs will perform under various environmental conditions, including temperature fluctuations, humidity, and exposure to light during storage and transportation.

(2) Durability: Ensure that the PET packaging is durable enough to protect the product under the expected conditions, including rough handling and potential impacts during shipping.

5. Recycling and Environmental Impact

(1) End-of-Life Considerations: PET plastic sheet roll is recyclable, but it’s important to consider how the packaging will be disposed of or recycled after use. Developing a recycling strategy or using recycled PET (rPET) can contribute to sustainability goals.

(2) Eco-Friendly Design: Consider the environmental impact of the packaging design, including the amount of material used and the potential for reducing waste.

6. Printing and Labeling

(1) Adhesion of Inks and Labels: Ensure that printing and labeling can adhere well to PET surfaces. The packaging may require special treatments to enhance ink adhesion, especially for critical information such as batch numbers and expiration dates.

(2) Legibility and Durability: The printed information on PET platic sheet roll packs must remain legible and intact throughout the product’s lifecycle, including after exposure to sterilization processes or environmental stress.

7. Thermoforming Process

(1) Forming Consistency: PET must be consistently thermoformed to ensure that each blister pack meets the exact specifications required for the medical product. Inconsistent forming can lead to defects that compromise the packaging’s integrity.

(2) Tooling and Equipment: The design and quality of the thermoforming equipment and tools must be optimized for PET, taking into account the material’s properties to achieve precise and uniform packaging.

8. Cost Considerations

(1) Material Costs: While PET is cost-effective, it’s important to balance material costs with performance requirements, especially for high-volume production. Evaluate the overall cost-benefit ratio, considering long-term factors like recyclability and material efficiency.

(2) Production Efficiency: Consider the efficiency of producing PET blister packs, including potential waste, cycle times, and energy consumption during manufacturing. Optimizing these factors can lead to cost savings.

9. Patient and User Safety

(1) Ease of Use: Ensure that the PET blister packaging is easy to open and handle by patients and healthcare providers, while still maintaining tamper-evidence and child-resistance features where necessary.

(2) Tamper Evidence: Incorporate features that clearly show if the packaging has been tampered with, which is crucial for ensuring the safety of medical products.

|

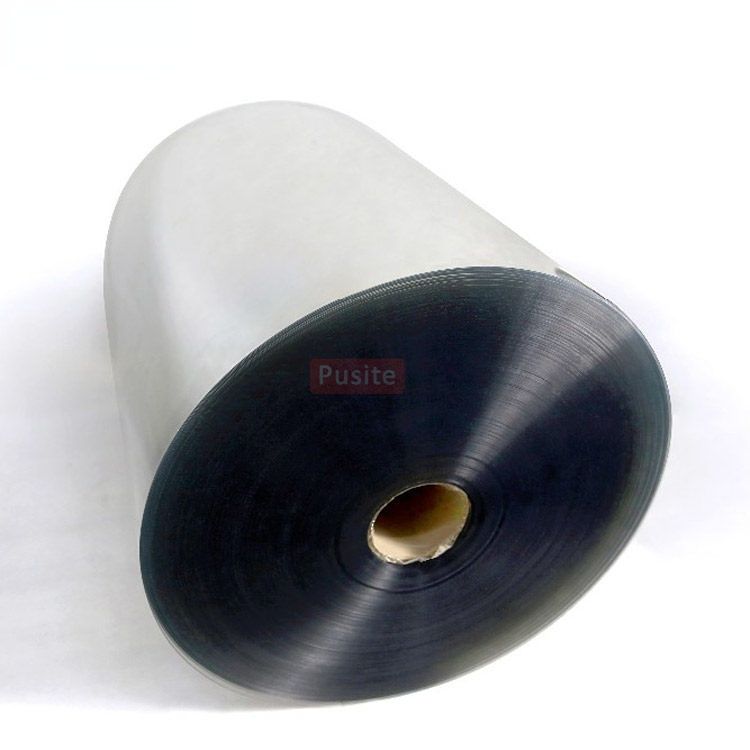

Product Name |

PET Plastic Sheet Rolls for Medical Blister Packaging |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.