About Indonesia Customers

With the change of consumer lifestyle and the increase in demand for convenient packaging materials, the application of packaging industry, especially PET plastic sheet rolls in food, beverage and personal care fields will continue to expand.

The packaging market in Indonesia is expected to see a surge in demand in the next few years, so our customer chose to open a new packaging company in Indonesia. He contacted us through our official website. Through communication, we learned that the customer himself owns a food company and can be the first customer of the new packaging company. This internal demand not only ensures the initial sales volume, but also helps the company quickly establish a production and sales system and reduce the risk of market development.

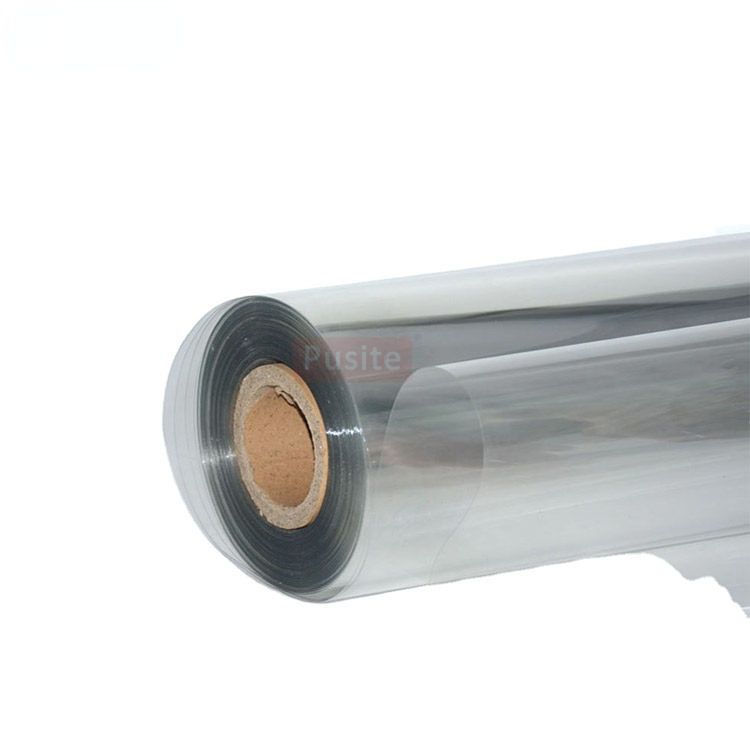

Based on customer needs, the sales team recommended 1.25mm thick and 900mm wide transparent PET plastic sheet rolls for food packaging. This specification is the most widely used in the market and is very suitable for customers' food packaging needs.

Indonesia customer felt that we were very professional in both products and services, so he placed an order of 8 tons with us. The following is our delivery video:

About PET plastic sheet rolls

PET (polyethylene terephthalate) plastic sheet roll is a material widely used in the packaging industry, favored for its unique characteristics and versatility.

Features of Pet plastic sheet rolls

1. High safety: PET plastic sheet roll meet food safety standards, do not contain harmful substances to the human body, and can be safely used to hold food.

2. High transparency and gloss: PET plastic sheet roll have high transparency and good gloss, making them very suitable as packaging materials that require high visibility and aesthetics.

3. Good mechanical properties: PET plastic sheet roll have high strength and rigidity, are wear-resistant, and are suitable for making products of various shapes and sizes.

4. Heat resistance: PET plastic sheet roll can withstand high temperatures and are not easily deformed or softened, so they are suitable for packaging applications that require high temperature processing.

5. Easy to process: PET plastic sheet rolls can be efficiently produced through processes such as extrusion and injection molding, with high production efficiency and suitable for large-scale production.

6. Recyclability: PET plastic sheet rolls can be recycled, reducing the impact of waste on the environment, and are an environmentally friendly material.

Application of Pet plastic sheet rolls

PET plastic sheet rolls are widely used in the field of food packaging, used to hold yogurt, jelly, beverages and other foods. In addition, PET sheets can also be used in electronic components, pharmaceutical packaging, industrial supplies and other fields.

We can supply Pet plastic sheet rolls

| Product name | Pet plastic sheet rolls, Polyethylene Terephthalate sheet rolls, PET Roll stock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

Future development prospects of Pet plastic sheet rolls

PET (Polyethylene Terephthalate) plastic sheet rolls have several promising future development prospects, driven by both technological advancements and market demands:

1. Recycling Innovations: There's a growing emphasis on sustainability and recycling in the plastics industry. Innovations in PET recycling technologies will likely lead to increased use of recycled PET (rPET) in sheet roll production. This supports circular economy principles and reduces dependence on virgin PET.

2. Advanced Processing Techniques: Continuous advancements in extrusion and forming technologies allow for thinner, stronger, and more cost-effective PET plastic sheet rolls. This includes developments in inline processing, which improve efficiency and reduce energy consumption.

3. Functional Additives: Incorporating additives such as UV stabilizers, antimicrobial agents, and barrier coatings enhances PET sheet rolls' performance. These additives expand the applications of PET in packaging, construction, and automotive industries by providing tailored properties like enhanced durability and barrier protection.

4. Application Diversification: PET plastic sheet rolls are versatile and find applications in various industries beyond traditional packaging, such as automotive interiors, electronics, and medical packaging. As new applications emerge, demand for PET sheet rolls is expected to grow.

5. Regulatory Landscape: Increasing regulations on single-use plastics and packaging materials encourage manufacturers to develop sustainable alternatives. PET, being recyclable and lightweight, is well-positioned to meet these regulatory requirements, further boosting its demand.

6. Global Market Growth: The global market for PET plastic sheet rolls is expanding, driven by economic growth, urbanization, and increasing disposable incomes in emerging markets. This growth provides opportunities for manufacturers to expand their production capacities and innovate new products.

Overall, the future of PET plastic sheet rolls looks promising, supported by technological advancements, regulatory trends, and expanding market opportunities across various industries.