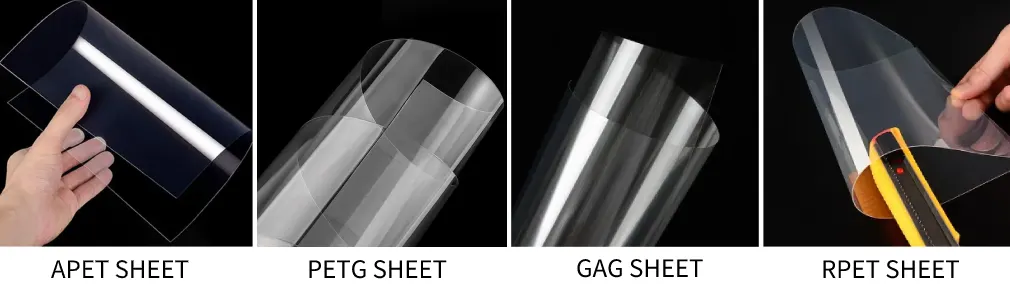

The polyester sheet series includes PETG, APET, CPET, etc., which are new sheet products developed and developed rapidly in recent years.

Polyester sheet has many advantages such as excellent comprehensive performance, high transparency, good strength, and easy post-processing. Due to its good strength, products of the same thickness have significantly better protection than PVC sheets. The polyester sheet is non-toxic, odorless and tasteless, and meets the hygienic requirements of food packaging. The processing of polyester sheet (blister or folding box) is convenient, and the ordinary blister machine can process it normally, and the efficiency is the same as that of PVC sheet.

APET plastic sheet

1. Properties

APET English full name: Amorphous Polyethylene Terephthalate, chemical name: Amorphous Polyethylene Terephthalate, is a blister material.

APET plastic sheet has a glossy surface, good electrical insulation, and is resistant to organic solvents such as dilute acid and dilute alkali. It has high safety and can be directly used in food packaging.

2. Advantages

① Lighter specific gravity: PET (specific gravity 1.33) is 3.7% lower than PVC (specific gravity 1.38).

② High strength: PET plastic sheet can withstand -40 ℃ without embrittlement, so usually a 10% thinner sheet is used to replace PVC.

③ Good folding resistance: PET sheet does not appear self-cracking crease like PVC.

④ PET sheet has high transparency and better gloss than PVC sheet, which is more suitable for exquisite packaging.

⑤ The PET sheet has no pollution and no crystal points.

3. Application of APET sheet

A-PET environmentally friendly plastic sheets are widely used in packaging of cosmetics, food, electronics, toys, printing and other industries, such as various blister packaging, folding boxes, plastic tubes, windows, etc.

APET film

Transparent and clean APET ordinary sheet, suitable for folding box, printing, blister.

APET color sheet

Transparent or opaque sheets of various colors, suitable for high-demand packaging of cosmetics and food.

APET extruded sheet

Immediately after molding, apply a transparent protective film. It can be single-sided lamination or double-sided lamination. It is suitable for packaging or printing with extremely high requirements on the surface of the sheet.

APET anti-UV sheet

UV means ultraviolet, anti-ultraviolet APET sheet.

CPET plastic sheet

1. Properties

CPET is a new type of material with good transparency, good permeability resistance, colorless, odorless, non-toxic, fresh-keeping, good barrier properties, high temperature resistance of 240°C and low temperature resistance of 40°C.

2. Purpose

● Applied to airline lunch box

● Applicable to tableware that can be heated in microwave ovens

● Oven plate

PETG plastic sheet

1. PETG characteristics

● Outstanding thermoforming properties

PETG plastic sheets are easy to produce products with complex shapes and large stretch ratios. Also, unlike PC board and impact-modified acrylic, this board does not require pre-drying prior to thermoforming. Compared with PC board or acrylic, its molding cycle is short, the temperature is low, and the yield is higher.

● Toughness

Extruded sheets of PETG sheet are typically 15 to 20 times tougher than general-purpose acrylic and 5 to 10 times tougher than impact-modified acrylic. PETG sheet has sufficient bearing capacity during processing, transportation and use to help prevent cracking.

● Weather resistance

PETG sheet provides excellent weather resistance. It keeps the product tough and prevents yellowing. It contains UV absorbers that can be co-extruded into a protective layer that protects the sheet from the harmful effects of UV rays.

● Easy to process

PETG sheets can be sawed, die-cut, drilled, punched, sheared, riveted, edge-milled and cold-formed without breaking. Minor scratches on the surface can be removed with a heat gun. Solvent bonding is also routine. It is easier to process than general-purpose acrylic, impact-modified acrylic or PC board, and can be processed by flocking, electroplating, static electricity, etc.

● Excellent chemical resistance

PETG sheets are resistant to many chemicals and common cleaning agents.

● Environmental friendly

PETG sheet substrates are all environmentally friendly materials and meet the requirements of food contact management.

● Economy

It is cheaper than PC board and more durable than acrylic.

2. PETG application fields

Films and sheets: all kinds of food, medicine, non-toxic and sterile packaging materials; packaging materials for textiles, precision instruments, and electrical components; Electrical insulating materials, capacitor films, flexible printed circuit boards and membrane switches and other electronic fields and mechanical fields.

Application of packaging bottle: its application has been developed from carbonated beverages to beer bottles, edible oil bottles, condiment bottles, medicine bottles, cosmetic bottles, etc.

Electronic appliances: manufacture of connectors, coil bobbins, integrated circuit housings, capacitor housings, transformer housings, TV accessories, tuners, switches, timer housings, automatic fuses, motor brackets and relays, etc.

Auto parts: such as switchboard covers, ignition coils, various valves, exhaust parts, distributor covers, measuring instrument covers, small motor covers, etc., and the excellent paintability, surface gloss and rigidity of PET can also be used to manufacture automobiles exterior parts.

Mechanical Equipment: Manufacture of gears, cams, pump housings, pulleys, motor frames and clock parts.