Material Composition:

PP PlasticPrice Range:

$1.25-$1.89/kgPP plastic roll factory Shpusite has 12 years of domestic and overseas sales experience. Now Shpusite has long-term cooperation with internationally renowned companies such as Apple, and has won unanimous praise from customers in more than 60 countries. As one of the largest plastic sheet manufacturers and suppliers in China, Shpusite can provide bulk food grade PP polypropylene plastic sheet rolls at very competitive market prices. We sincerely hope to cooperate with you to achieve mutual benefit and win-win results. Welcome to visit our factory and talk with us face to face to create a better future!

PP (Polypropylene) plastic rolls have emerged as a popular choice in the cosmetic packaging industry due to their exceptional properties and versatility. As consumer demand for sustainable and visually appealing packaging grows, PP plastic rolls provide an ideal solution for manufacturers looking to enhance their product presentation while ensuring product integrity.

1. Lightweight and Durable: PP plastic rolls are lightweight but offers excellent strength, making it ideal for packaging that needs to protect products while being easy to handle.

2. Chemical Resistance: Polypropylene plastic rolls are resistant to most chemicals, making it perfect for holding cosmetic products like creams, lotions, and perfumes without degradation.

3. Eco-Friendly: PP plastic rolls are recyclable, contributing to sustainability in cosmetic packaging.

4. Good Transparency: While not as clear as PET, PP can offer a good level of transparency for showcasing products inside the packaging.

5. Moldable: PP plastic rolls can be easily molded into various shapes, ideal for custom cosmetic packaging designs.

PP plastic rolls are not only suitable for cosmetic tray packaging, but can also be widely used in a variety of other product packaging.

1. Food packaging

(1) Frozen food: PP plastic rolls can be used to make frozen food packaging, such as frozen vegetables and ready-to-eat meal boxes.

(2) Cooked food packaging: used to package cooked food, salads and ready-to-eat snacks, with good sealing and moisture resistance.

2. Pharmaceutical packaging

(1) Pharmaceutical bottles and containers: PP is used in the pharmaceutical industry to manufacture bottles and containers for medicines to ensure the safety and stability of medicines.

(2) Capsule packaging: PP plastic rolls are also suitable for the packaging of pharmaceutical capsules and tablets, which can effectively prevent moisture and pollution.

3. Daily necessities packaging

(1) Cleaning products: bottles and containers for various cleaners and detergents.

(2) Personal care products: such as soap, shampoo and conditioner packaging.

4. Industrial product packaging:

(1) Tools and accessories: packaging for hand tools and small accessories, providing good protection and easy storage.

(2) Mechanical parts: can be used for packaging mechanical parts to ensure safety during transportation.

The production of PP plastic sheet rolls for cosmetic packaging involves the following main steps:

1. Raw Material Preparation: Select transparent or semi-transparent polypropylene (PP) pellets and add necessary additives, such as antioxidants and UV absorbers.

2. Extrusion Molding: Heat and melt the PP pellets, then extrude them into a thin film using an extruder. Techniques such as flat film extrusion or blown film forming can be employed.

3. Cooling and Shaping: Rapidly cool the film using cooling rollers or a water tank, and then wind it into rolls.

4. Post-Processing: Perform cutting, rolling, and surface treatments (such as printing or coating) to enhance appearance and performance.

5. Quality Control: Conduct quality checks on the film for thickness, transparency, and other parameters to ensure compliance with cosmetic packaging standards.

6. Packaging and Shipping: Package the qualified film rolls and arrange for shipping.

This process ensures the production of high-quality PP plastic sheet rolls that meet market demands and are widely used in cosmetic packaging.

|

Product Name |

PP Plastic Rolls for cosmetic packaging |

|

Material |

PP vacuum forming material , 100% raw material |

|

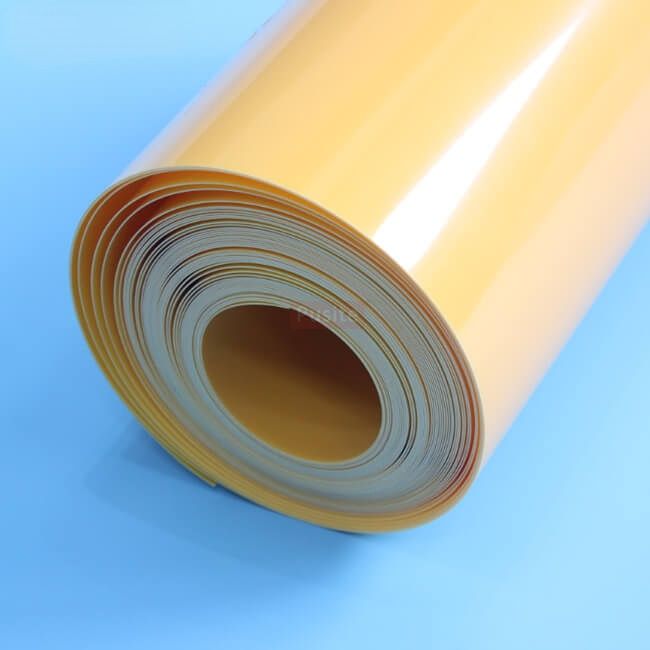

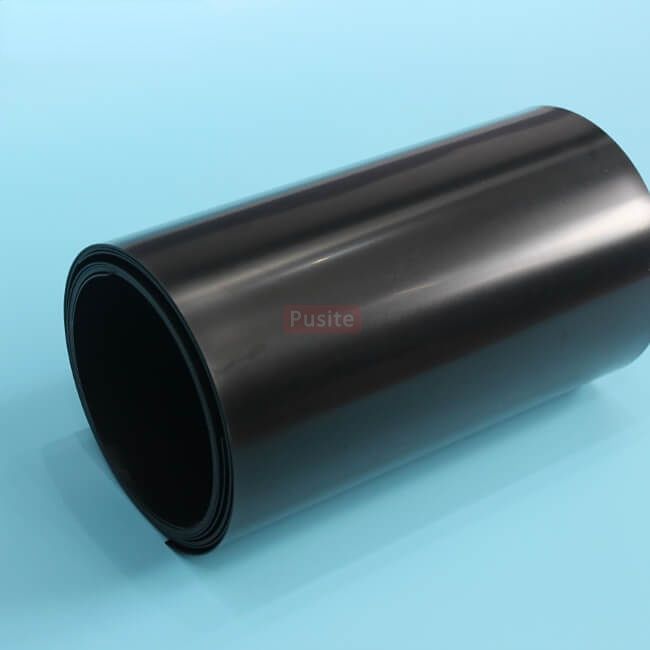

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.