Polypropylene (PP) plastic sheet rolls are indeed suitable for frozen food packaging. PP is a versatile and durable material known for its excellent moisture barrier properties, resistance to low temperatures, and ability to maintain its strength and flexibility even when exposed to freezing conditions. These qualities make PP plastic sheet rolls ideal for packaging frozen foods, as they help preserve the food's freshness and protect it from freezer burn.

Additionally, PP is a food-safe material that is resistant to many chemicals and does not leach harmful substances, making it a popular choice in the food packaging industry. The material is also recyclable, contributing to sustainability efforts in packaging.

What is PP Plastic Sheet Rolls for frozen food packaging?

Polypropylene plastic sheet roll is a polymer formed by addition polymerization of propylene. It is a colorless, odorless, non-toxic, and translucent solid substance. Polypropylene particles are dyed, plasticized at high temperature and extruded into polystyrene sheets. PP sheets have chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties. PP sheet has high transparency, good barrier properties, low density, non-toxic and hygienic, and can be recycled. It will not produce toxic and harmful gases when heated or burned, does not harm human health, and does not corrode equipment. It is a new type green environmental protection packaging materials.

PP Plastic Sheet Rolls Physical and Chemical Properties

| Melting temperature | 130°C |

| Typical injection temperature | 32-66 °C |

| Heat distortion temperature | 100°C (under 0.46 MPa pressure) |

| Tensile strength | 32 MPa |

| Flexural strength | 41 MPa |

| Specific gravity | 0.91 |

| Shrinkage rate | 1.5-2.0% |

Features and advantages of PP Plastic Sheet Rolls

1. Chemical resistance: Diluted alkalis and acids do not react with PP plastic sheet rolls, which makes it an ideal container for this type of liquid.

2. Elasticity and toughness: PP plastic sheet roll is elastic within a certain range of deflection, and will undergo plastic deformation without cracking in the early stage of deformation, so it is usually regarded as a “tough” material.

3. Fatigue resistance: PP retains its shape after a lot of twisting and bending.

4. Insulation: PP plastic sheet rolls has high resistance and is an insulating material.

5. Transmittance: It can be made into a transparent color, but it is usually made into a natural opaque color with a certain color transmittance.

PP Plastic Sheet Rolls for frozen food packaging

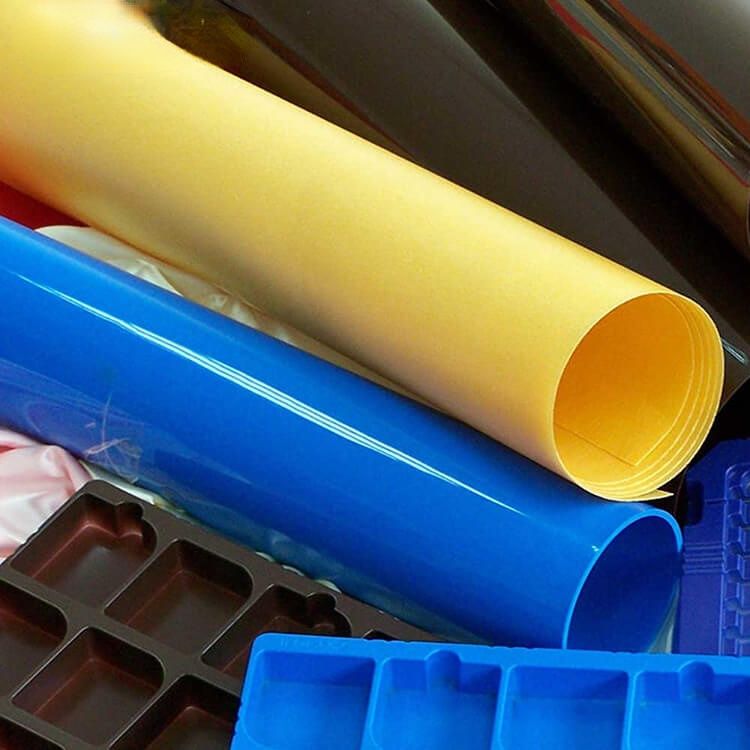

Common specifications of PP blister sheets include the following:

Thickness: 0.2mm-2.0mm

Width: 300mm-850mm

Color: clear, Natural, Black, White, Color, Customized according to needs.

Length: customized according to customer needs

Applications of PP Plastic Sheet Rolls

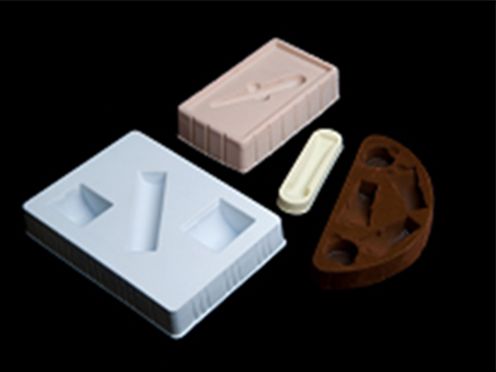

PP plastic sheet rolls have made our lives more changes and improvements, and made our lives more convenient. PP products are common in our lives, and PP sheets are used in a wide range. There are many products made of it in our lives. It can be made into various products through secondary processing such as thermoforming, which are mainly used for packaging of food, medicine, medical equipment, etc.

1. Medical device packaging: PP plastic sheet rolls medical device packaging boxes are used to hold medical devices. They have good sterilization performance and can ensure the health and safety of medical devices.

2. Cosmetic packaging: PP plastic sheet rolls cosmetic boxes are used to package cosmetics with exquisite appearance and can enhance product quality.

3. Stationery packaging: PP plastic sheet rolls stationery boxes are used to package stationery, which are lightweight, durable and easy to store.

4. Industrial parts packaging: PP plastic sheet rolls industrial parts trays are used to hold industrial parts, are dust-proof and moisture-proof, and are easy to transport.

What are the advantages of PP Plastic Sheet Rolls in frozen food packaging?

Advantages of PP (Polypropylene) Plastic Sheet Rolls in Frozen Food Packaging:

1. Low-Temperature Resistance: PP material exhibits good toughness and impact resistance under low-temperature conditions. It does not become brittle due to freezing, ensuring the integrity of the packaging during freezing and thawing processes.

2. High Chemical Resistance: PP plastic sheet roll is highly resistant to water, acids, alkalis, and various chemicals, preventing chemical reactions between the packaging material and the food, thereby maintaining food safety and flavor.

3. Good Transparency: PP plastic sheet rolls can be made into transparent or semi-transparent packaging, allowing consumers to directly observe the condition of the food, enhancing product display appeal.

4. Excellent Barrier Properties: PP plastic sheet rolls has certain gas and water vapor barrier properties, effectively extending the shelf life of food by preventing moisture and oxygen from entering the packaging, thus maintaining the freshness of the food.

5. Environmental Friendliness: PP plastic sheet roll is a recyclable plastic material, reducing environmental pollution. Moreover, it does not release harmful gases when burned, offering good environmental performance.

6. Lightweight and High Strength: PP plastic sheet rolls are lightweight but have high tensile strength and abrasion resistance, helping to protect food during transportation and storage, and reducing the risk of packaging damage.

7. Cost-Effective: Compared to other high-performance packaging materials, PP plastic sheet rolls are lower in cost, making them a cost-effective packaging choice.

These characteristics make PP plastic sheet rolls an ideal material for frozen food packaging, widely used in packaging various frozen foods such as meat, seafood, vegetables, and pasta.

More products