Material Composition:

Red HIPS PlasticPrice Range:

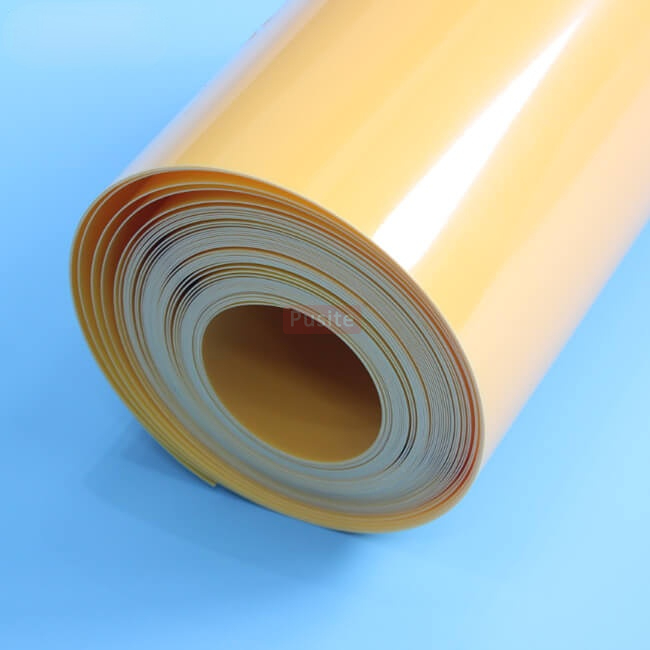

$1.35-$1.88/kgRed HIPS plastic roll is a versatile plastic material known for its toughness, impact resistance, and affordability. It is commonly used in food, toy, automotive parts and consumer goods various packing.

Red HIPS plastic rolls refer to rolls of High Impact Polystyrene (HIPS) plastic that are tinted or dyed red. HIPS is a versatile plastic material known for its toughness, impact resistance, and affordability. It is commonly used in food, toy, automotive parts and consumer goods various packing.

The red HIPS plastic rolls is both practical and beautiful. For example, in the packaging of some special products, red plastic packaging boxes can be used to attract attention or convey specific information. In packaging, red HIPS rolls can be used for branding or to differentiate a product from competitors.

These rolls often come in different thicknesses and widths to suit different fabrication or fabrication needs. We can then also customize the red HIPS plastic rolls according to the customer' s specific requirements.

|

|

1. Packaging: Red HIPS plastic rolls can be used to create packaging materials such as blister packs, clamshells, trays, and containers for products ranging from electronics to food items.

2. Thermoforming: Red HIPS plastic can be easily thermoformed into various shapes using heat, making it suitable for manufacturing products like cups, lids, and other disposable items.

3. Printing: Red HIPS plastic rolls can be printed on directly, allowing for branding, labeling, or adding instructional information to packaging materials.

4. Point-of-Purchase Displays: The bright red color can be eye-catching, making it suitable for point-of-purchase displays in retail environments.

5. Crafts and DIY Projects: Hobbyists and DIY enthusiasts may use red HIPS rolls for crafting projects, model making, or prototyping due to its ease of manipulation and affordability.

6. Signage: Red HIPS plastic rolls can be used for indoor signage or displays, where a vibrant color is desired.

|

Product Name |

Red HIPS Plastic Rolls Manufacturer China Factory Price |

|

Material |

HIPS vacuum forming material , 100% raw material |

|

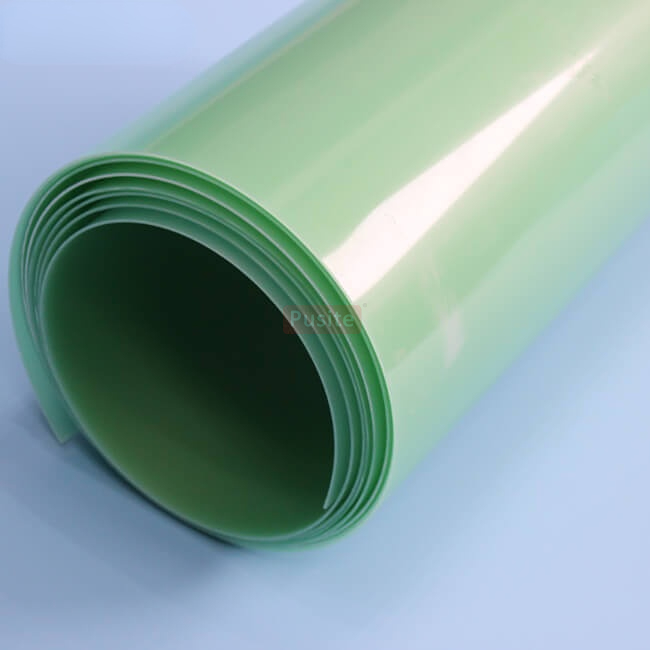

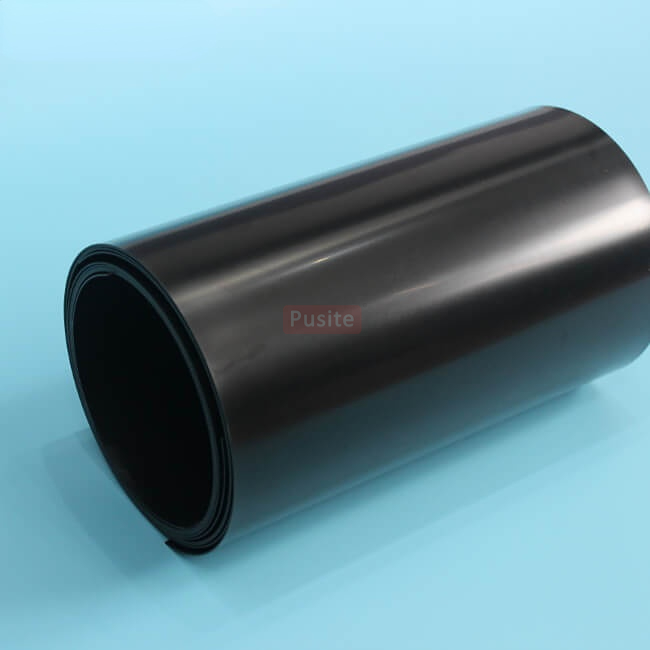

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

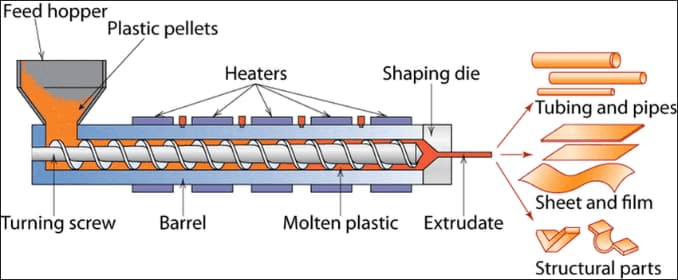

The production process of red HIPS (High Impact Polystyrene) plastic rolls typically involves several steps, including compounding, extrusion, coloring, and rolling. Here’s an overview of the production process:

1.Raw Material Preparation

The production begins with the preparation of raw materials. Polystyrene resin, which is derived from petroleum, is the primary raw material used in HIPS production. The resin is typically supplied in pellet form.

2. Compounding

In the compounding stage, additives such as impact modifiers, colorants (in this case, red pigments), UV stabilizers, and processing aids are mixed with the polystyrene resin pellets. The compounding process ensures that the final HIPS material meets the desired specifications for strength, impact resistance, color, and other properties.

3. Extrusion

The compounded HIPS material is then fed into an extruder, which melts the resin and forms it into a continuous molten mass. The extruder consists of a screw mechanism that applies heat and pressure to the material, forcing it through a die to shape it into a thin, continuous sheet or film.

4. Coloring

During the extrusion process, colorants are added to achieve the desired red hue. The red pigments are thoroughly mixed with the molten HIPS material to ensure uniform color distribution throughout the plastic sheet.

5. Calendering

After extrusion, the molten HIPS material may undergo calendering, a process where the plastic sheet is passed between a series of polished rollers to improve its surface finish and thickness uniformity. Calendering can also enhance the mechanical properties of the HIPS plastic sheet.

6. Cooling and Solidification

Once the red HIPS sheet is formed, it is rapidly cooled using air or water to solidify the material and prevent distortion. Cooling rates and conditions are carefully controlled to ensure uniformity and quality in the final product.

7. Rolling

The cooled and solidified HIPS sheet is then fed into a series of rollers, where it is wound onto large rolls. These rolls of red HIPS plastic represent the final product and can vary in width, thickness, and length according to customer specifications.

8. Quality Control

Throughout the production process, quality control measures are implemented to monitor the physical, mechanical, and visual properties of the red HIPS plastic rolls. This ensures that the final product meets industry standards and customer requirements.

When choosing red HIPS (High Impact Polystyrene) plastic rolls, there are a few key factors to consider to ensure you choose a product that meets your needs:

1. Application requirements: First, determine your specific application requirements. Consider how you plan to use these red HIPS plastic rolls, such as packaging, printing, thermoforming, etc. Different applications may require different thicknesses, sizes and properties.

2. Thickness and Size: Choose the appropriate thickness and size based on your application requirements. Thicker HIPS rolls generally have higher impact resistance and stiffness and are suitable for applications requiring more strength, while thinner rolls may be better suited for flexible packaging or printing purposes.

3. Color Uniformity: Ensure that the red HIPS plastic roll you purchase is uniform in color. Color differences between batches may affe

|

Product Name |

Red HIPS Plastic Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.