Surface conductive polystyrene (PS) plastic rolls are commonly used for thermoforming applications, including the production of electronic trays. These trays are essential for safely handling and transporting electronic components, which are often sensitive to static electricity.

Key Features

The following are the advantages of surface conductive PS plastic rolls for thermoformed electronic pallets

1. Surface Conductivity

Antistatic Properties: Surface conductive PS plastic has antistatic properties, which help in dissipating static electricity. This is crucial for protecting electronic components from electrostatic discharge (ESD).

Surface Resistivity: The material typically has a surface resistivity in the range of 10^5 to 10^9 ohms/square, which ensures effective static dissipation.

2. Thermoformability

Heat Resistance: Surface conductive PS plastic rolls can be easily heated and molded into various shapes, making it ideal for thermoforming processes.

Precision Forming: The material can be formed with high precision, ensuring that the resulting trays have the exact dimensions and features needed for electronic components.

3. Durability

Impact Resistance: Surface conductive PS plastic rolls is known for its good impact resistance, which is essential for protecting delicate electronic parts during transport and handling.

Chemical Resistance: It also offers resistance to many chemicals, adding an extra layer of protection for sensitive electronic components.

4. Cost-Effectiveness

Material Cost: Polystyrene is relatively inexpensive compared to other engineering plastics, making it a cost-effective choice for large-scale production.

Product Application

Surface conductive polystyrene (PS) plastic rolls are especially suitable for creating various types of packaging solutions aimed at protecting electronic components. Here’s an overview of how these applications are leveraged:

1. Electronic Component Trays

Organization: These trays help in systematically arranging electronic components, making it easier to identify and retrieve specific parts.

Storage: They provide a safe environment for storing components, minimizing the risk of damage.

Transportation: Ensures that components are securely held in place during transit, preventing physical damage and reducing the risk of static discharge.

2. Blister Packaging

Protection: Encases small electronic parts, shielding them from environmental factors such as dust, moisture, and mechanical impact.

Visibility: The clear nature of PS plastic allows for easy visual inspection of the components without opening the package.

Convenience: Blister packs are lightweight and can be designed with easy-open features for quick access to the components.

3. ESD Protective Packaging

Electrostatic Discharge Protection: Prevents static build-up and discharges that could damage sensitive electronic components.

Additional Layer of Security: Especially important for highly sensitive components that require extra protection beyond standard antistatic measures.

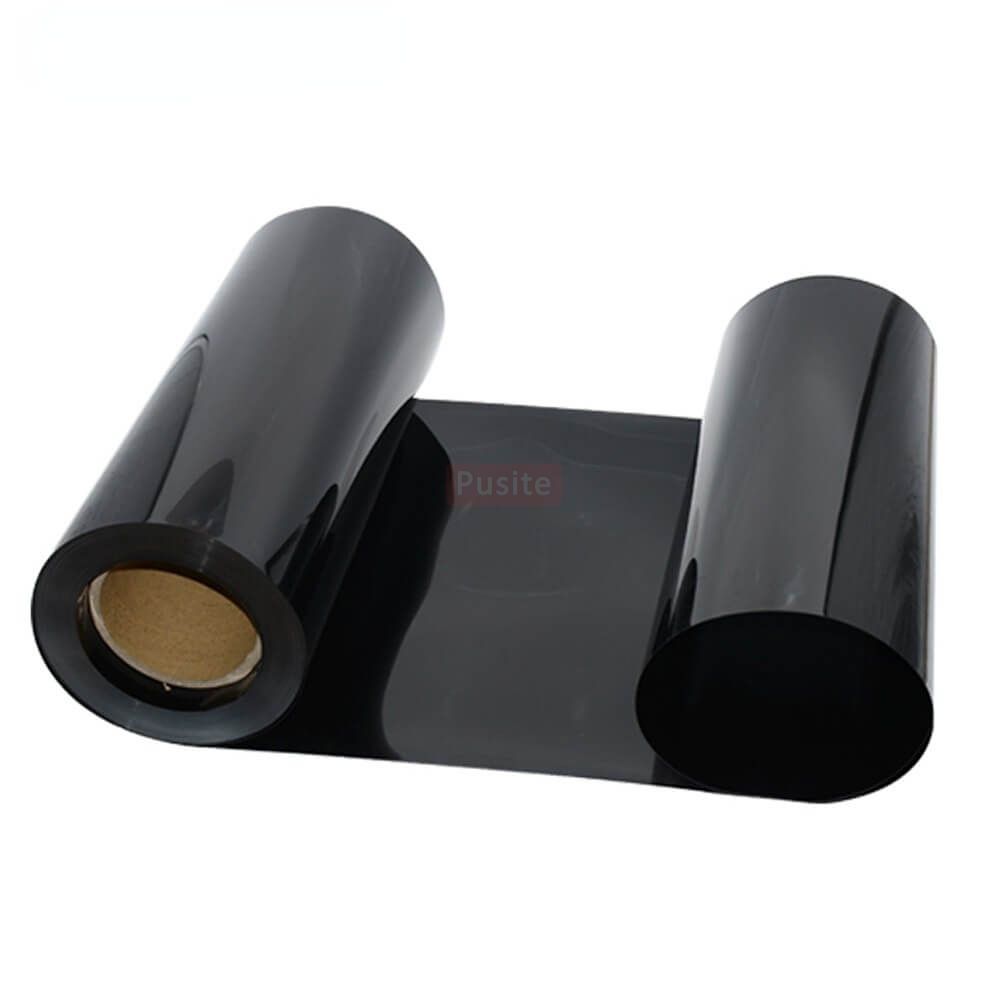

Surface conductive PS plastic roll

Surface conductive PS (polystyrene) plastic roll is a type of polystyrene plastic film roll that possesses surface conductivity. This material achieves its conductive properties by incorporating conductive agents into the surface of the polystyrene substrate.

Manufacturing Method

The production of this material typically involves the following steps:

Substrate Preparation: Select polystyrene rolls with appropriate thickness and specifications.

Conductive Agent Addition: Apply or incorporate conductive agents onto the surface of the polystyrene. Common conductive agents include carbon powder, metal particles, or conductive polymers.

Forming and Processing: Process the treated polystyrene rolls into the desired dimensions and shapes to produce the final product.

Thermoforming Process

Sheet Heating: The PS plastic roll is unwound and passed through heaters to reach the appropriate forming temperature.

Forming: The heated sheet is then fed into a thermoforming machine where it is shaped into the desired tray design using a mold.

Cooling and Trimming: The formed trays are cooled and trimmed to the final dimensions.

Selecting the Right Material

When selecting a surface conductive PS plastic roll for thermoforming electronic trays, consider the following:

1. Surface Resistivity Requirements: Ensure the material meets the specific ESD protection requirements for your application.

2. Thickness of the Roll: Depending on the size and weight of the components to be stored, choose an appropriate thickness for durability and protection.

3. Supplier Quality: Source the material from reputable suppliers to ensure consistency in quality and performance.

4. Suppliers and Standards: Look for suppliers who specialize in ESD protective materials and adhere to industry standards such as ANSI/ESD S20.20 for ESD control.

Pusite conductive PS plastic roll is a versatile and cost-effective solution for thermoforming electronic trays. It is your best choice and we look forward to your consultation.