Material Composition:

HIPS PlasticPrice Range:

$1.28-$1.99Thermoforming impact resistance HIPS plastic rolls are a type of plastic rolls material that is specifically designed for use in the thermoforming process. Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature and then shaped into a mold. Whether you're packaging food, electronics, or consumer goods, these sheets provide the performance and versatility you need to create high-quality packaging solutions.Pusite is a professional manufacturer of HIPS plastic rolls.

Thermoforming Impact Resistant HIPS (High Impact Polystyrene) plastic rolls are specially modified materials designed for the thermoforming process. They offer exceptional impact resistance while retaining the excellent processing properties of polystyrene. Widely used in industries such as packaging, consumer goods, electronics, and automotive, these plastic rolls provide durability and strength while maintaining a cost-effective solution. With excellent thermoforming characteristics, they are the ideal material for creating durable, impact-resistant products.

1. High Impact Resistance

Thermoforming Impact Resistant HIPS plastic rolls are engineered to provide superior impact resistance compared to standard polystyrene. This enhanced impact strength ensures that the material can withstand significant physical stress without cracking or breaking, making it ideal for protective packaging and other high-impact applications.

2. Excellent Thermoforming Properties

These plastic rolls are highly suitable for thermoforming, where the material is heated to a pliable temperature and shaped into molds. It retains its shape after cooling, offering precise and detailed molding for various packaging and product designs.

3. Wide Range of Applications

Commonly used for food packaging, pharmaceutical packaging, and electronic product packaging, Thermoforming Impact Resistant HIPS is perfect for producing thermoformed blister packaging, food trays, packaging boxes, and more.

4. Cost-Effective Solution

Thermoforming Impact Resistant HIPS plastic rolls offer a great balance of high performance and affordability. Compared to other high-impact materials, they provide a cost-effective option without compromising on quality or durability, making them an ideal choice for businesses seeking high-quality yet affordable packaging solutions.

5. Environmentally Friendly

The material is made from recyclable components, making it an environmentally friendly option. It meets the growing demand for sustainable solutions in manufacturing and packaging.

Technical Specifications

Material: High Impact Polystyrene (HIPS)

Thickness Range: 0.2mm – 2.0mm

Width Range: Customizable according to customer requirements

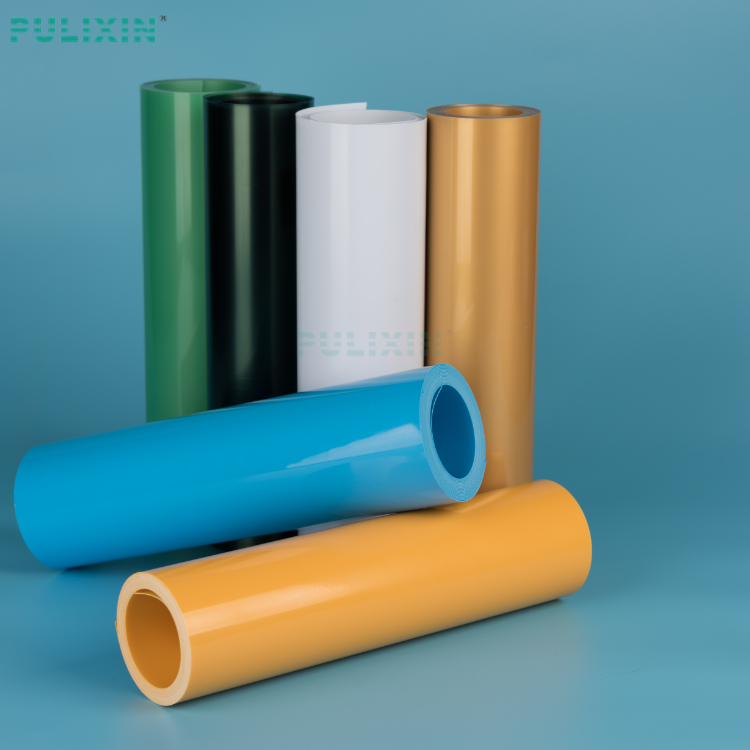

Color Options: White, black, and other customized colors

Impact Strength: Enhanced by up to 50% compared to standard PS

Surface Treatment: Available in matte, glossy, or other custom

Food Packaging: Used in producing transparent food trays and packaging boxes, ensuring food safety and integrity during transportation and storage.

Electronic Product Packaging: Ideal for creating protective casings or packaging for electronic products, providing additional impact resistance to prevent damage.

Medical Packaging: Used for pharmaceutical packaging and protective cases for medical devices, ensuring safe delivery to consumers.

Thermoforming Impact Resistant HIPS plastic rolls, with their outstanding impact resistance, excellent thermoforming properties, and broad range of applications, are the ideal material for packaging, consumer goods, electronics, and more. Whether you need a cost-effective, durable solution for product protection or want to improve manufacturing efficiency, these plastic rolls provide a reliable and high-performance option.

When choosing the right Thermoforming Impact Resistant HIPS plastic roll, the following aspects should be considered:

1. Impact resistance: According to the application requirements, select materials with sufficient impact resistance to ensure that the product can be effectively protected during the packaging process.

2. Thermoforming performance: Ensure that the plastic roll has good thermoforming properties and can be easily formed and maintain its shape after heating.

3. Thickness and width: According to the size and strength requirements of the product, select the appropriate thickness (usually 0.2mm to 2.0mm), and the appropriate width to adapt to the production line.

4. Surface treatment: Select the required surface effect (such as glossy or matte) to meet the appearance and functional requirements of the product packaging.

5. Environmental protection: Confirm whether the material meets environmental protection standards and has good recyclability.

6. Cost and supply stability: Balance product performance and cost, and ensure that suppliers provide a stable supply and reasonable prices.

In short, the selection should be based on product protection requirements, processing performance and budget. If you have any custom requirements or technical inquiries, feel free to contact us. We will provide professional services and support tailored to your needs.

|

Product Name |

Thermoforming Impact Resistance HIPS Plastic Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.