Advantages of HIPS plastic rolls for cosmetic packaging

HIPS plastic rolls (high impact polystyrene plastic sheet roll), is a commonly used plastic packaging material. It has the following advantages, making it an ideal choice for cosmetic packaging.

1. Durability: HIPS is known for its high impact resistance, making it ideal for packaging products that may be subjected to rough handling or drops. This ensures the cosmetic products remain intact and undamaged during transportation and use.

2. Aesthetic Appeal: HIPS can be easily molded and comes in various finishes, including glossy and matte. This allows for attractive packaging designs that can enhance the visual appeal of cosmetic products.

3. Printability: HIPS provides an excellent surface for printing, which is essential for branding and labeling. High-quality graphics and text can be easily applied, ensuring the packaging effectively communicates the product's brand and information.

4. Cost-Effective: Compared to other plastics, HIPS is relatively inexpensive, making it a cost-effective option for manufacturers without compromising quality.

5. Ease of Fabrication: HIPS is easy to fabricate and thermoform, allowing for the creation of complex shapes and designs. This flexibility is particularly useful for cosmetic packaging, where unique and custom designs are often desired.

6. Lightweight: HIPS is lightweight, which helps in reducing shipping costs and improving ease of handling for consumers.

7. Chemical Resistance: HIPS is resistant to a wide range of chemicals, ensuring that the packaging does not react with the cosmetic products it contains. This maintains the integrity and safety of the products.

8. Recyclability: HIPS is recyclable, making it a more environmentally friendly option compared to some other plastics. This is increasingly important as consumers and companies focus on sustainability.

9. Barrier Properties: HIPS offers good barrier properties against moisture and gases, which helps in preserving the shelf life and quality of cosmetic products.

These advantages make HIPS plastic rolls a popular choice for cosmetic packaging, balancing functionality, aesthetics, and cost-efficiency.

What is HIPS plastic rolls?

HIPS plastic rolls are rolls of High Impact Polystyrene (HIPS) material that are wound into rolls for ease of transport, storage, and processing. HIPS is a versatile, cost-effective thermoplastic known for its toughness, impact resistance, and ease of fabrication.

Characteristics of HIPS Plastic Rolls

High Impact Resistance: HIPS is designed to withstand impact, making it less likely to crack or break under stress.

Easy to Form: HIPS can be easily thermoformed, meaning it can be heated and shaped into a variety of forms and designs, making it highly versatile for different applications.

Lightweight: Despite its strength, HIPS is lightweight, which can reduce shipping costs and make handling easier.

Cost-Effective: HIPS is generally less expensive compared to other thermoplastics, making it a popular choice for large-scale production.

Specifications of HIPS Plastic Rolls

| Product Name | HIPS plastic roll |

|---|---|

| Material | HIPS vacuum forming material , 100% raw material |

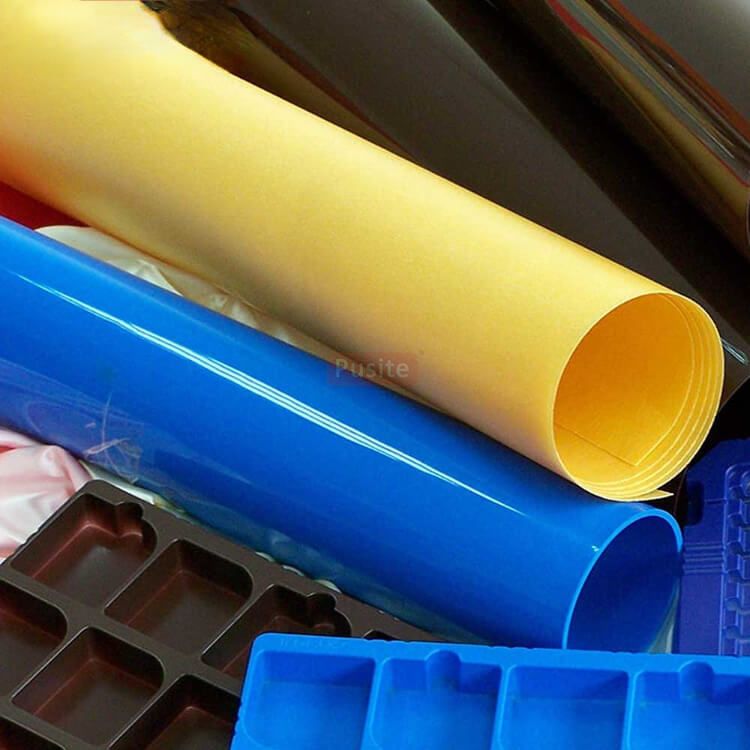

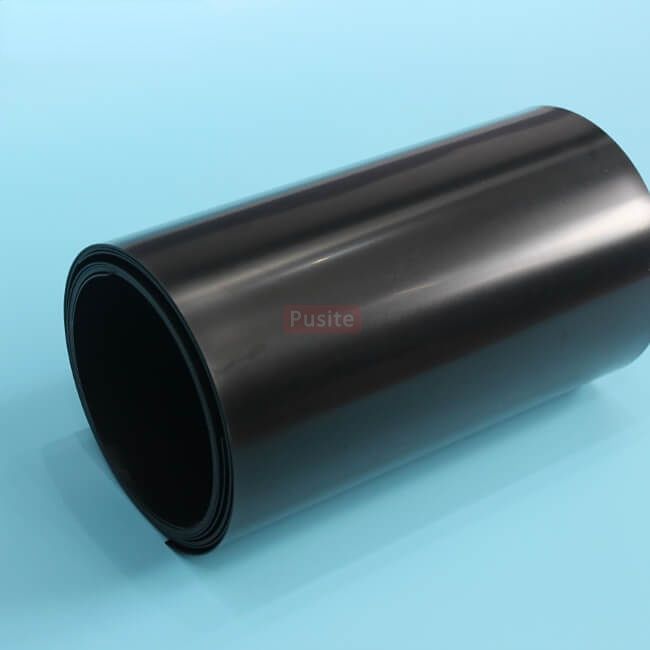

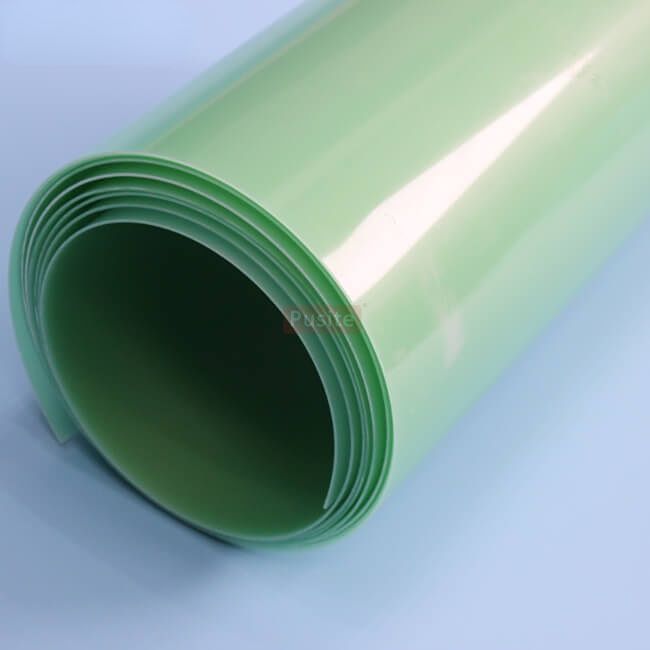

| Color | Transparent,black,green or any customized color |

| Thickness Tolerance | According to GB (higher than GB) |

| Application | Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

| Width | 300~1400mm or Customized |

| Thickness | 0.15~3mm or Customized |

| Special Treatment | Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive. |

| Features | 1.High temperature resistance, not easily melted 2.Easy to peel off and no residue requirement 3.Printable, good inking effect 4.Widely used in food and drug industry 5.Uniform thickness, smooth surface/beautiful sand ripples 6.No grains, contamination control and good processing performance |

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping ,air transportation, express,land transportation |

| Payment Term | Credit card ,T/T,L/C,Western Union,Paypal |

| Mass Production Lead Time | 3-15 days depend on order quantity |

| Certificate | ROHS,MSDS,TDS,SGS,ISO9001 |

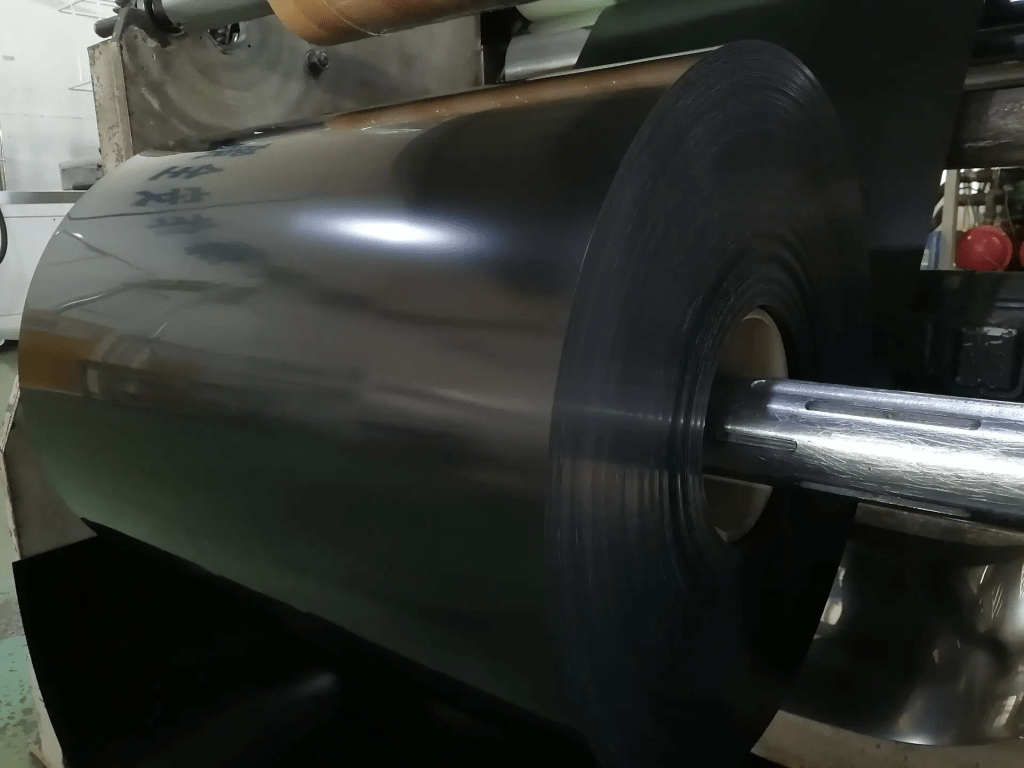

| Core Diameter | 3 inch or 6 inch depend on customer requirement |

| Packing | Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet for each roll |

Applications of HIPS Plastic Rolls

Packaging: Widely used in packaging for products that require durable, protective, and attractive packaging, such as cosmetic products, food containers, and electronic goods.

Household Items: Commonly found in products like refrigerator liners, vacuum cleaner parts, and other durable household goods.

Medical: Used for disposable medical products and trays due to its ease of sterilization and forming.

Production Process of HIPS Plastic Rolls

Extrusion: HIPS plastic rolls are typically produced through an extrusion process where the plastic is melted and forced through a die to create a continuous sheet.

Winding: The continuous sheet is then cooled and wound into rolls.

Custom Processing: These rolls can later be cut, printed, or thermoformed into the desired shapes and sizes as per the application requirements.

Pusite Advantages

Pusite (Shanghai) International Trade Co., Ltd. was established in 2009 in Shanghai, which is a production, sales and trade integration company.We can provide you with more favorable prices.

HIPS sheet rolls we offer

| Sheet type | Width mm | Thickness mm | Color | Resistance value Ω |

|---|---|---|---|---|

| HIPS normal sheet | 200-800 | 0.3-2 | Any | / |

| High impact HIPS | Any | / | ||

| HIPS black conductive | 200-800 | 0.3-2 | Black | 10^4-10^6 |

| HIPS black semi-conductive | Black | 10^6-10^9 | ||

| HIPS black volume conductive | Black | 10^4-10^6 | ||

| HIPS polymer sheet | Any | 10^8 | ||

| HIPS anti-static sheet | Any | 10^9-10^11 | ||

| HIPS coated sheet | Any | 10^3-10^9 |

Benefits in Cosmetic Packaging

Enhanced Aesthetics: Ability to create visually appealing packaging.

Protection: Provides robust protection for delicate cosmetic products.

Customization: Allows for custom shapes and designs to suit branding needs.

Efficiency: Streamlines production and reduces costs due to ease of processing and forming.

HIPS plastic rolls are a highly functional and economical material choice for a wide range of industries, particularly favored in applications where durability, printability, and cost-effectiveness are key considerations.

More products