Application of PET plastic sheets

PET plastic sheets have the following uses:

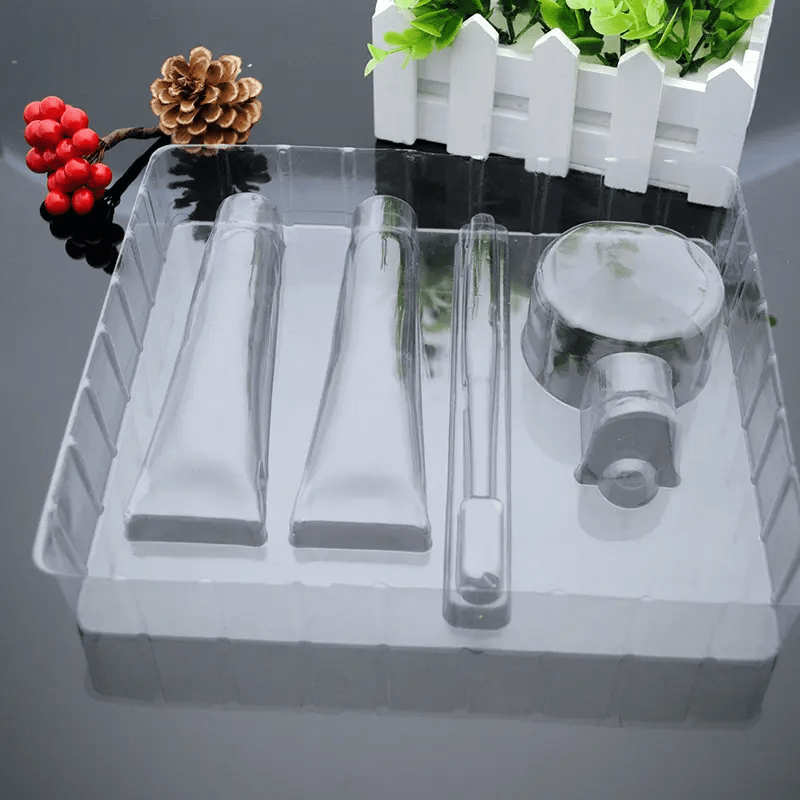

1. Blister Packaging: PET plastic sheets are used to create transparent blister packs for items like electronics, medical devices, and food products. They offer a secure yet visible packaging solution.

2. Food Trays and Containers: PET plastic sheets are widely used to produce plastic trays and containers for fresh food, such as fruits, vegetables, and bakery items. They are lightweight and provide a barrier that helps maintain freshness.

3. Beverage Lids: PET plastic sheets can be thermoformed into lids for beverage cups, offering transparency and strength to protect the contents.

4. Pharmaceutical packaging: Pet plastic sheets are used in the pharmaceutical industry to package drugs and medical devices to ensure product safety and effectiveness.

5. Cosmetic packaging: Pet plastic sheet is used for containers and lids of cosmetics and skin care products, providing good sealing and display effects.

6. Electronic product packaging: Pet plastic sheet is protect electronic components and equipment from moisture and damage.

7. Industrial component packaging: Pet plastic sheets are used to package mechanical parts and accessories to ensure safety during transportation.

8. Label and sticker packaging: Pet plastic sheet rolls is can be used to make water-resistant and wear-resistant label packaging.

Advantages of PET plastic sheets

PET plastic sheet has the following advantages:

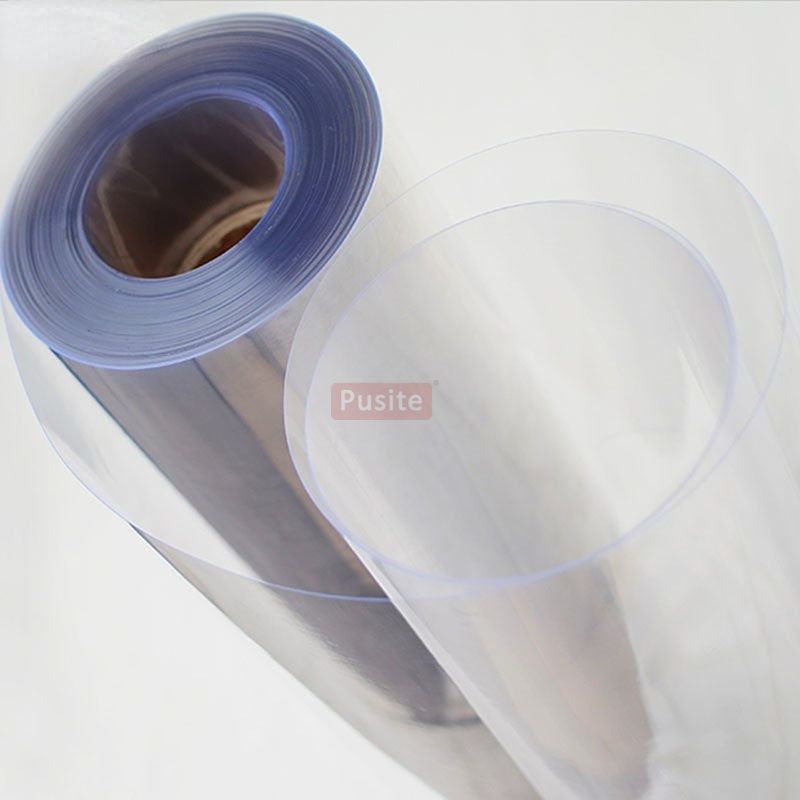

1. Excellent Clarity: PET plastic sheets can provides high transparency, enhancing product visibility and appeal.

2. Good Barrier Properties: PET plastic sheets offers resistance to moisture, gases, and UV light, protecting contents from spoilage and degradation.

3. High Strength and Durability: PET plastic sheets are withstands impact and puncture, ensuring the safety of packaged goods.

4. Heat Resistance: PET plastic sheets are suitable for various applications that require high-temperature processing or storage.

5. Lightweight: PET plastic sheets reduces shipping costs and makes handling easier.

6. Recyclability: PET plastic sheets can be recycled, contributing to sustainability and reducing environmental impact.

7. Chemical Resistance: PET plastic sheets have resistant to many chemicals, making it versatile for different applications.

8. Cost-Effectiveness: PET plastic sheets can provides good performance at a competitive price, making it a popular choice for manufacturers.

These advantages make PET plastic sheets ideal for a wide range of packaging and industrial applications.

About of PET plastic sheets

PET plastic sheets are a kind of thermoplastic plastic film made of polyethylene terephthalate (PET).

Physical and Chemical Properties

| Water absorption | 0.06%~0.129% |

| Impact strength | 64.1~128J/m |

| Rockwell hardness | M 90~95 |

| Elongation | 1.8%~2.7% |

| Melting point | 250~255°C |

| Operating temperature | -100~120°C |

| Flexural strength | 148~310MPa |

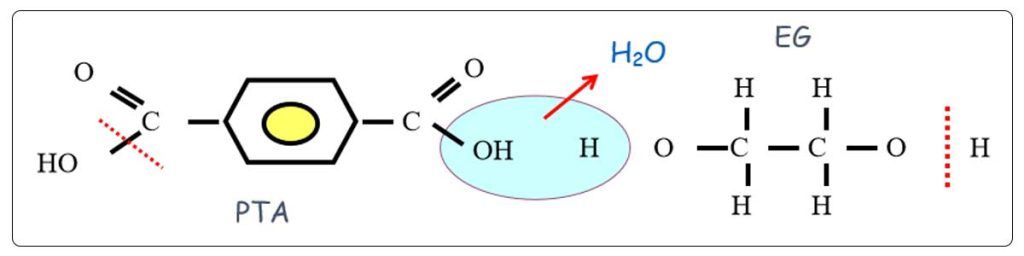

Chemical structure of PET material

PET plastic sheets has the following characteristics:

Transparency: PET film generally has good transparency, making it very popular in packaging and display applications.

Chemical resistance: It has good resistance to a variety of chemicals and is suitable for various industrial applications.

Strength and toughness: Relatively high mechanical strength and toughness make it not easy to break during transportation and use.

Heat resistance: It can remain stable within a certain temperature range and is not easy to deform.

Recyclability: PET material is recyclable, which helps to protect the environment.

More Products