There are some key differences between conductive PP (polypropylene) rolls and conductive PS (polystyrene) rolls in terms of performance, application and characteristics. Here are the main differences between them:

Material properties

Conductive PP Rolls

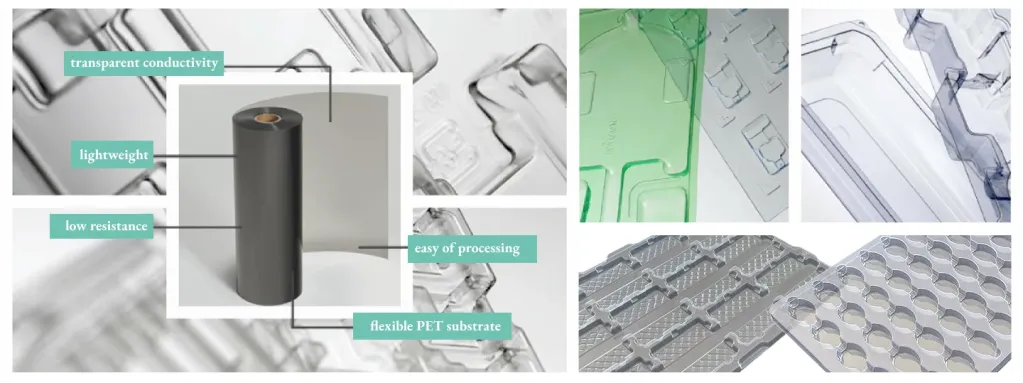

Lightweight: PP plastic material itself is light and suitable for applications that need to reduce weight.

Toughness: PP plastic has good toughness and impact resistance, making it superior in mechanical strength.

Chemical resistance: PP plastic has strong resistance to a variety of chemicals and is suitable for chemical and medical applications.

Conductive PS Rolls

Transparency: PS plastic has good transparency and can be used for packaging that needs to display content.

Rigidity: PS plastic material has good rigidity, but relatively high brittleness and may break under impact.

Formability: PS is easy to process and form, suitable for products with complex shapes.

Conductive properties

Both are conductive by adding conductive fillers (such as carbon black or metal powder), but conductive PP usually achieves a better balance between conductivity and heat resistance, while conductive PS may show better conductivity in low temperature environments.

ESD PP sheet roll

- Width: 300~800mm

- Thickness: 0.3~2.0mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

- Molding Process: Vacuum forming

- Conductive polystyrenesheet Surface resistance can reach 10^4~10^6.

- Semi-conductive polystyrenesheet Surface resistance can reach 10^6~10^9.

- Ordinary anti-static polystyrenesheet Surface resistance can reach 10^9~10^12.

- Permanent anti-static polystyrenesheet The surface resistance is as high as 10^6~10^9.

ESD HIPS sheet roll

- Width: 300~850mm

- Thickness: 0.2~2.0mm

- Weight: 50-150kg/roll

- Shape: Roll/Sheet

- Molding Process: Vacuum forming

- Conductive polystyrenesheet Surface resistance can reach 10^4~10^6.

- Semi-conductive polystyrenesheet Surface resistance can reach 10^6~10^9.

- Ordinary anti-static polystyrenesheet Surface resistance can reach 10^9~10^12.

- Permanent anti-static polystyrenesheet The surface resistance is as high as 10^6~10^9.

Thermal stability

Conductive PP: has good high temperature resistance and is suitable for high temperature processing and applications.

Conductive PS: has low heat resistance and is easily deformed in high temperature environments, and is not suitable for high temperature applications.

Application areas

Conductive PP rolls: are widely used in anti-static packaging of electronic components, chemical industry, medical devices, automotive parts, etc., suitable for applications requiring strength and chemical stability.

Conductive PS rolls: are mainly used in packaging of electronic products, disposables and transparent containers, etc., suitable for applications requiring transparent display and lower costs.

Cost:

Conductive PS rolls are usually less expensive and are suitable for large-scale production and disposable occasions, while conductive PP sheets may be slightly more expensive in terms of performance and durability.

Environmental impact:

PP materials are relatively more environmentally friendly and are favored for their recyclability and lower environmental impact. PS materials have certain challenges in recycling.

Conductive PP rolls and conductive PS rolls have their own advantages and disadvantages. Choosing the right material requires comprehensive consideration based on the needs, performance requirements and cost-effectiveness of the specific application. For applications that require toughness, chemical resistance and high temperature stability, conductive PP is more suitable; for applications that require transparency and low cost, conductive PS may be a better choice.