Material Composition:

HIPS PlasticPrice Range:

$1.25-$1.69/kgPusite's wholesale vacuum forming HIPS (High Impact Polystyrene) plastic rolls are made of 100% pure raw materials, ensuring the product's high strength and durability. This gives it superior stability and reliability during the vacuum forming process.

Our wholesale vacuum forming HIPS plastic rolls are high-quality materials specifically designed for a variety of vacuum forming applications. HIPS (High Impact Polystyrene) is renowned for its excellent formability, durability, and cost-effectiveness, making it an ideal choice for numerous industries.

1. High Impact Resistance: HIPS plastic rolls offer outstanding impact strength, ensuring that formed products are less prone to damage during transportation and use.

2. Easy to Form: This material is easy to shape when heated, making it suitable for complex mold designs and precise detail replication.

3. Lightweight: HIPS plastic rolls are lightweight, helping to reduce the weight of the final product while maintaining strength.

4. Eco-Friendly: HIPS is recyclable, meeting environmental standards and reducing environmental impact.

5. Multiple Specifications: We provide HIPS plastic rolls in various thicknesses and widths to meet diverse customer needs.

1. Food Packaging: Used for producing food trays, containers, and lids, compliant with food safety standards.

2. Electronics: Ideal for manufacturing protective casings and liners for electronic products.

3. Medical Devices: Suitable for producing disposable medical devices and packaging.

4. Retail Displays: Used for creating display stands, trays, and packaging boxes.

5. Industrial Components: Ideal for manufacturing various industrial parts and enclosures.

| Product Name | Wholesale Vacuum Forming HIPS Plastic Sheet |

| Material | 100% virgin HIPS raw material |

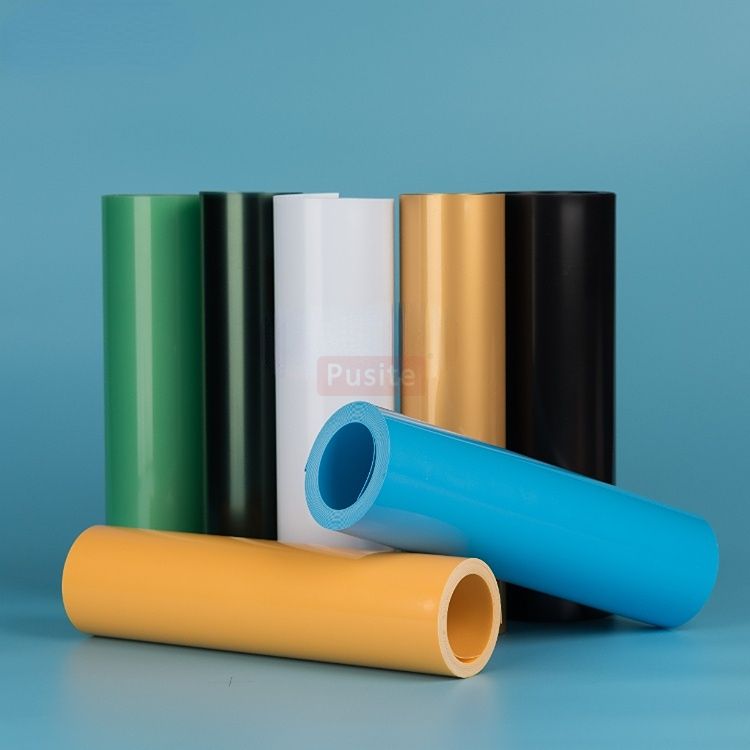

| Color | Any color |

| Certificate | SGS, ROHS, ISO, etc. |

| Grade | Medical grade, food grade, and conductive grade |

| Width | 300~1400mm |

| Thickness | 0.15~3mm |

| Application | Mainly applied to the packaging of food, medicine, electronics, cosmetics & gifts. |

| Our Advantage |

|

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping, air transportation, express, land transportation |

| Payment Term | Credit card, T/T, L/C, Western Union, Paypal |

| Surface | Glossy/matt |

| Form | By roll or cut sheet form |

The reasons for choosing Pusite Wholesale Vacuum Forming HIPS Plastic Rolls can be explained from the following aspects:

1. High quality materials

Pusite's HIPS (High Impact Polystyrene) plastic rolls are made of 100% pure raw materials, ensuring the high strength and durability of the product. This makes it have superior stability and reliability during the vacuum forming process.

2. Customized services

Pusite can provide customized color and specification services according to the specific needs of customers. This means that you can choose any color and size of Vacuum Forming HIPS Plastic Rolls you want, making the packaging perfectly match the brand image.

3. Wide range of applications

This plastic roll is widely used in many industries such as food, pharmaceuticals, electronics, cosmetics and gift packaging to meet the packaging needs of different fields. It has good formability and transparency, suitable for high-end packaging solutions.

4. Strict quality control

Pusite has a strict QC (quality control) team with a quality satisfaction rate of 99%. Each batch of products will be strictly tested to ensure that it meets the highest quality standards. This is the confidence guarantee for customers in long-term cooperation.

5. Obtain multiple certifications

The products have passed multiple international certifications such as SGS, ROHS, ISO, etc. to ensure compliance with global standards and regulatory requirements. This is especially important for industries that require compliance (such as medicine, food, etc.).

6. High cost performance

Pusite's HIPS plastic rolls are still very cost-effective. By optimizing the production process, the HIPS plastic rolls provided by Pusite can effectively control costs while ensuring quality, ensuring that customers get high-quality and competitive prices.

In general, choosing Pusite Wholesale Vacuum Forming HIPS Plastic Rolls means that you will get a high quality, high-performance and flexible plastic roll that can effectively support your packaging needs in various industries.

Here’s a brief overview of precautions for using Vacuum Forming HIPS Plastic Rolls:

1. Storage: Keep rolls in a cool, dry place, away from direct sunlight and heavy pressure to prevent deformation.

2. Temperature: Heat the plastic to the recommended temperature (150-200°C) for optimal forming results.

3. Handling: Use gloves to avoid fingerprints and scratches, and handle with care to prevent damage.

4. Cutting: Use proper cutting tools for clean edges, and be cautious of sharp edges after trimming.

5. Ventilation: Ensure proper ventilation when heating to avoid inhaling fumes.

6. Recycling: Recycle used plastic according to local guidelines for environmental sustainability.

These precautions help ensure the best results and safety when using HIPS plastic rolls.

|

Product Name |

Wholesale Vacuum Forming HIPS Plastic Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.