Reasons for HIPS Plastic Rolls as Food Packaging Trays

As the food packaging industry evolves, there is an increasing demand for sustainable, cost-effective, and high performance materials that meet both consumer and regulatory expectations. High Impact Polystyrene (HIPS) plastic rolls are gaining popularity as an ideal choice for food packaging trays, thanks to their exceptional features and benefits across several key factors:

Material Performance and Food Safety

HIPS plastic is known for its excellent rigidity, durability, and ease of molding, making it a reliable option for food packaging trays. Its high-impact resistance ensures that food products remain safe during transportation and handling. Importantly, HIPS is approved for direct food contact by regulatory bodies, ensuring that the material meets food safety standards. It is also highly resistant to moisture, oils, and fats, making it ideal for a variety of food items, from fresh produce to ready-to-eat meals.

Environmental and Sustainability Considerations

As sustainability becomes a key priority for the packaging industry, HIPS plastic rolls offer a responsible choice. The material is 100% recyclable, which helps reduce waste and supports circular economy initiatives. Moreover, HIPS is made from petrochemical sources that are increasingly being adapted for eco-friendly practices, making it an important player in reducing the environmental footprint of packaging materials.

Cost-Effectiveness and Production Efficiency

HIPS plastic rolls provide a cost-effective solution for food packaging manufacturers. The material is inexpensive to produce and easy to process, leading to lower production costs. Additionally, HIPS can be thermoformed into various tray shapes and sizes with high efficiency, reducing waste and maximizing production output. This helps food packaging companies streamline their manufacturing processes while ensuring high-quality standards.

Industry Trends and Regulatory Drivers

The global food packaging industry is witnessing a shift towards more sustainable materials due to regulatory pressures and consumer demand for eco-friendly products. Governments and organizations are pushing for stricter regulations on packaging waste, and HIPS plastic rolls are well-positioned to meet these standards. Many countries are now imposing bans on single-use plastics, and HIPS provides a sustainable alternative that can align with new policies and regulations, making it a future-proof material for food packaging.

Consumer Experience and Brand Value

HIPS packaging trays not only offer superior product protection but also enhance the consumer experience. With its clear, glossy finish, HIPS trays provide an aesthetically pleasing presentation that improves product visibility and appeal. For brands, using HIPS can help build a positive image by aligning with consumer preferences for safe, high-quality, and sustainable packaging. This can lead to increased brand loyalty and consumer trust, contributing to long-term business success.

Technological Innovation

The evolution of HIPS plastic technology has led to improvements in its properties, including enhanced clarity, heat resistance, and printability. Innovations such as the development of biodegradable HIPS variants and advanced coating technologies have made it even more attractive for food packaging applications. These technological advancements enable brands to meet specific packaging requirements while maintaining product integrity and reducing environmental impact.

Global Supply Chain and Localized Production

The global demand for HIPS plastic rolls for food packaging is supported by a well-established supply chain that ensures consistent availability of the material. Local production facilities, including those in key markets, are able to manufacture and distribute HIPS plastic rolls efficiently, reducing lead times and ensuring quick response to market demands. Additionally, HIPS production is adaptable to various geographical locations, facilitating both local and international supply chain needs.

HIPS plastic rolls represent a forward-thinking choice for food packaging trays, offering a combination of safety, sustainability, cost-efficiency, and market alignment. As the packaging industry continues to prioritize performance and environmental responsibility, HIPS is becoming an indispensable material for food packaging solutions that meet the growing demands of consumers, regulators, and brands alike.

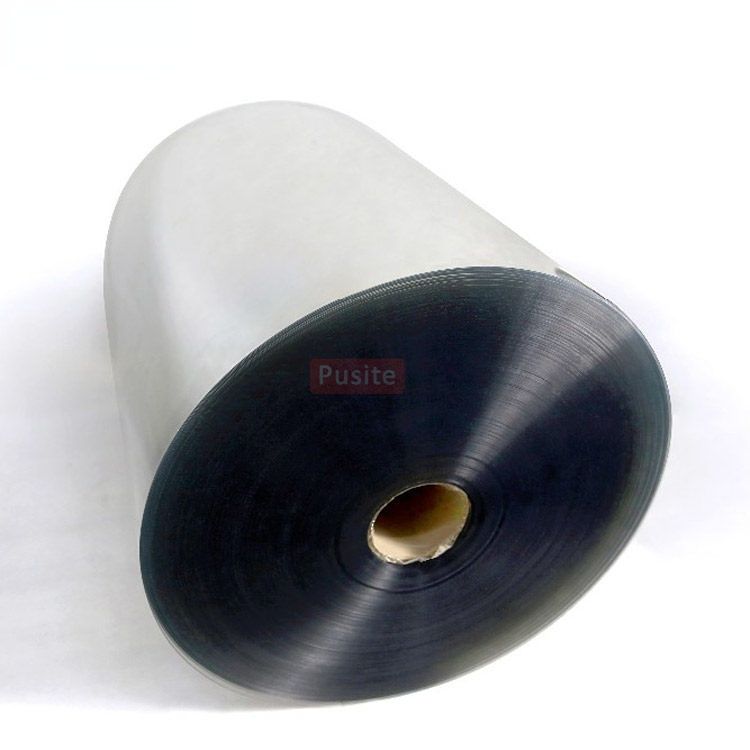

What is HIPS Plastic Rolls?

HIPS (High Impact Polystyrene) Plastic Rolls are a type of thermoplastic material known for their high impact resistance, rigidity, and ease of processing. HIPS is commonly used in a variety of industries, including packaging, electronics, food containers, and consumer goods.

Here are some key features of HIPS Plastic Rolls:

1. Impact Resistance: HIPS has a high impact strength, making it durable and resistant to breakage or cracking under stress.

2. Thermoforming Capability: HIPS is ideal for thermoforming processes, where it can be heated and molded into different shapes. This makes it popular in packaging applications for creating items like trays, lids, and clamshell containers.

3. Surface Quality: HIPS has a smooth surface, which makes it suitable for printing, coating, or applying labels, often used in consumer product packaging and promotional materials.

4. Versatility: HIPS plastic rolls can be used in a wide range of applications, from food packaging to parts for electronics, signage, and even displays.

5. Cost-Effective: HIPS is an affordable material, making it an attractive option for high-volume production where cost is a consideration.

What products can we provide?

Pusite can provide you with food grade HIPS plastic rolls, PP plastic rolls,PET plastic rolls.