In the world of manufacturing and packaging, selecting the right material for a specific process is crucial for ensuring efficiency, quality, and cost-effectiveness. When it comes to vacuum forming, HIPS plastic rolls (High Impact Polystyrene) have gained significant popularity as a preferred material. Known for its versatility, ease of use, and exceptional performance, HIPS plastic rolls are now recognized as one of the most reliable choices for vacuum forming applications.

What is Vacuum Forming?

Vacuum forming is a thermoforming process where a heated plastic sheet is draped over a mold, and a vacuum is applied to pull the sheet tightly against the mold, shaping it into the desired form. It is widely used for packaging, automotive parts, trays, and custom designs.

Why HIPS Plastic Rolls?

1. Easy to Mold and Shape: HIPS plastic rolls is known for its excellent thermoforming properties. It softens and becomes highly malleable when heated, making it easy to shape into complex forms. Whether you're creating intricate designs or simple shapes, HIPS plastic rolls can be precisely molded, ensuring high-quality results.

2. Durability and Strength: One of the standout features of HIPS plastic rolls is its impact resistance. It can withstand physical stresses without cracking or breaking, which makes it ideal for vacuum forming applications that require durability and long-term reliability. Whether used for protective packaging or product enclosures, HIPS provides a robust solution.

3. Cost-Effectiveness: HIPS plastic rolls is more affordable than other thermoforming materials, offering a cost-effective option without compromising quality. This affordability makes it a popular choice for industries seeking to reduce material costs while maintaining superior product performance.

4. Excellent Surface Finish: HIPS plastic rolls provide a smooth, aesthetically pleasing finish that is ideal for visual applications. It is easy to print on and can be textured or coated to meet specific requirements. This makes it a favored option for industries where both functionality and appearance are important.

5. Recyclable and Environmentally Friendly: As sustainability becomes a key focus for businesses globally, the recyclable nature of HIPS plastic makes it an attractive option. HIPS plastic can be reused, reducing environmental impact and helping businesses adhere to eco-friendly practices.

6. Wide Range of Applications: The versatility of HIPS plastic rolls extends across various industries. Whether in food packaging, medical trays, automotive parts, or electronics, HIPS can be adapted for numerous uses, thanks to its excellent balance of strength, flexibility, and ease of processing.

Applications of HIPS Plastic Rolls in Vacuum Forming

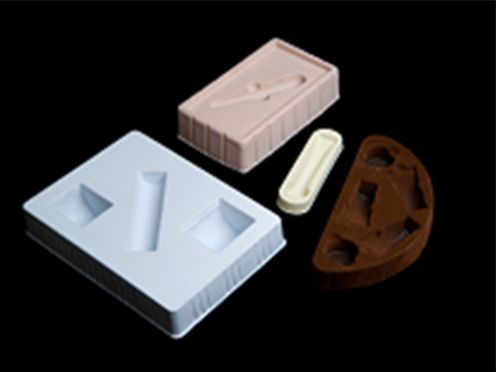

HIPS (High Impact Polystyrene) plastic rolls are widely used in vacuum forming due to their exceptional qualities, including moldability, strength, and versatility. Vacuum forming is a popular process where a heated sheet of plastic is stretched over a mold, then air is removed to form the plastic tightly to the shape of the mold. HIPS plastic is especially well-suited for this process, with numerous applications across a variety of industries.

Here are the key applications of HIPS plastic rolls in vacuum forming:

1. Food Packaging

HIPS plastic is commonly used in vacuum-formed food packaging, such as:

- Trays: For meats, fresh produce, bakery items, and deli products.

Clamshell Containers: For fast food, take-out packaging, and ready-to-eat meals. - Blister Packs: For single-serving food items, like snacks and confectionery.

HIPS’s ability to resist moisture, combined with its non-toxic properties, makes it an ideal choice for food-related packaging. Its clear surface also ensures that the contents are visible to consumers.

2. Medical Packaging and Trays

HIPS plastic is frequently used in medical and pharmaceutical packaging, including:

- Trays for Surgical Instruments: Vacuum-formed HIPS trays are used to store and protect medical instruments during sterilization and transport.

- Medical Blisters and Pouches: For pharmaceutical tablets and capsules.

- Protective Covers: HIPS provides lightweight yet durable protection for sensitive medical devices.

The rigidity and strength of HIPS, combined with its safety and ease of molding, make it a preferred material for the medical industry.

3. Consumer Goods Packaging

HIPS plastic rolls are used to create vacuum-formed packaging for various consumer products, such as:

- Electronic Enclosures: Lightweight protective casings for items like televisions, radios, and household appliances.

- Toys: Packaging that is molded to fit toys or hobby items securely.

- Cosmetic Packaging: For compact makeup cases, cosmetic trays, and skincare product containers.

The versatility of HIPS allows manufacturers to create custom designs, ensuring a secure fit for products while maintaining an appealing presentation.

4. Protective Packaging for Fragile Items

HIPS plastic rolls is also used to create protective packaging for fragile items like:

- Electronics: Custom-molded trays and inserts to hold electronics safely during shipping.

- Glassware: Vacuum-formed foam trays made from HIPS to hold delicate glass products.

- Ceramics and Furniture: Protection for fragile decorative pieces or furniture components during transit.

The strength of HIPS ensures that fragile items are well-protected while maintaining a light weight for easier handling.

5. Custom Molding for Specialized Products

HIPS plastic rolls can be used in custom vacuum forming for specialized products, such as:

- Prototype Development: Manufacturers often use HIPS to create prototypes for new product designs.

- Specialty Packaging: Customized solutions for unique-shaped products.

The flexibility of HIPS allows it to be shaped into various forms to meet the needs of different industries.

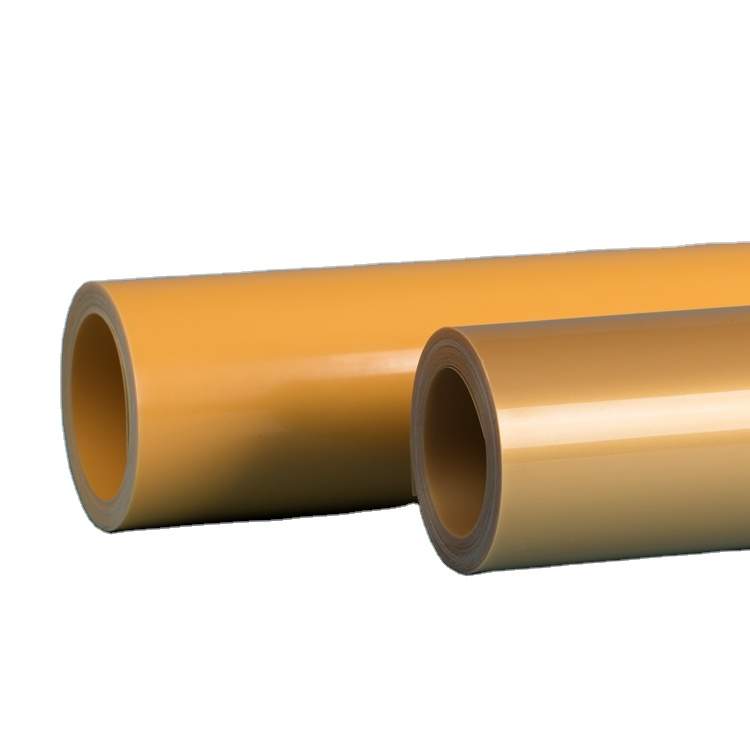

Pusite can provide HIPS plastic rolls

| Product Name | Vacuum Forming HIPS Plastic Sheet |

| Material | 100% virgin HIPS raw material |

| Color | Any color |

| Certificate | SGS, ROHS, ISO, etc. |

| Grade | Medical grade, food grade, and conductive grade |

| Width | 300~1400mm |

| Thickness | 0.15~3mm |

| Application | Mainly applied to the packaging of food, medicine, electronics, cosmetics & gifts. |

| Our Advantage |

|

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping, air transportation, express, land transportation |

| Payment Term | Credit card, T/T, L/C, Western Union, Paypal |

| Surface | Glossy/matt |

| Form | By roll or cut sheet form |

Why choose Pusite HIPS Plastic Roll?

At Pusite, we offer high quality HIPS (High Impact Polystyrene) plastic rolls that are perfect for packaging a wide range of products, here are the reasons why you should choose us:

1. Superior Quality: Our HIPS plastic rolls are manufactured to the highest standards, ensuring your products are durable and impact-resistant.

2. Cost-effective: We offer affordable solutions that don’t compromise on quality, helping you save on production costs.

3. Multiple Applications: Our HIPS rolls are perfect for a wide range of industries, including food packaging, medical, consumer goods, and automotive.

4. Customization: We offer custom sizes and specifications to meet your exact needs.

5. Reliable Delivery: With Pusite, you can count on timely and efficient delivery, ensuring your production runs smoothly.

6. Excellent Support: Our experienced team offers expert guidance to help you choose the right materials and ensure the best results.

Pusite is your trusted partner for high quality, affordable, and reliable HIPS plastic rolls. Let us help you with your manufacturing and packaging needs.